Call Today: 916-259-1868

In the realm of precision motion control, the voice coil stage has emerged as a transformative technology, offering unparalleled accuracy and responsiveness in various applications. According to recent industry reports, the global market for motion control systems is projected to reach approximately $24 billion by 2026, driven by the increasing demand for automation in sectors like robotics, aerospace, and semiconductor manufacturing. The voice coil stage plays a pivotal role in this growth, enabling precise linear and rotary movements with minimal latency.

In the realm of precision motion control, the voice coil stage has emerged as a transformative technology, offering unparalleled accuracy and responsiveness in various applications. According to recent industry reports, the global market for motion control systems is projected to reach approximately $24 billion by 2026, driven by the increasing demand for automation in sectors like robotics, aerospace, and semiconductor manufacturing. The voice coil stage plays a pivotal role in this growth, enabling precise linear and rotary movements with minimal latency.

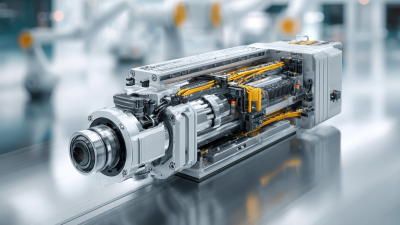

The voice coil stage operates on the principles of electromagnetic force, delivering high-performance motion capabilities that traditional systems struggle to match. This technology is particularly advantageous in high-speed applications, where quick and precise adjustments are critical. Research indicates that systems utilizing voice coil stages exhibit up to 30% improved accuracy compared to conventional linear actuators, which enhances productivity and reduces operational costs across various industries.

As industries continue to innovate, the integration of voice coil stages into complex systems not only enhances performance but also simplifies design and maintenance. With its ability to provide smooth, non-contact motion and high repeatability, the voice coil stage is set to revolutionize the landscape of precision control, making it an indispensable tool for engineers and manufacturers aiming to achieve higher efficiency and reliability in their operations.

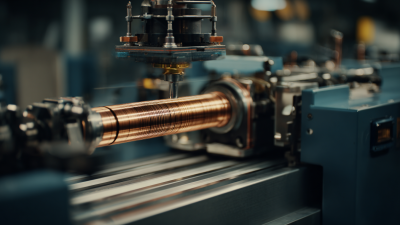

Voice coil technology has emerged as a pivotal advancement in motion control systems, primarily due to its ability to deliver rapid response times and exceptional accuracy. According to a report by MarketsandMarkets, the global motion control market is projected to reach $27.96 billion by 2025, growing at a CAGR of 7.2%. This growth is largely driven by the increasing demand for precise and efficient control in applications ranging from robotics to aerospace, where every millimeter counts. Voice coil stages, which utilize electromagnetic forces to create linear motion, offer unparalleled precision that is crucial in these high-stakes environments.

One of the significant advantages of voice coil stages is their ability to provide smooth, continuous motion without the backlash commonly associated with traditional systems. A study published by the IEEE highlighted that voice coil actuators could achieve positioning accuracy within ±0.5 micrometers, a feat that elevates them above conventional methods. This level of precision not only enhances the performance of equipment but also reduces wear and tear over time, leading to longer operational lifespans and reduced maintenance costs. As industries increasingly embrace automation and smart technologies, the adoption of voice coil technology will likely play a vital role in achieving the precision and control demanded by modern applications.

Voice coil stages have emerged as a pivotal technology in precision motion control, particularly in applications where accuracy and responsiveness are paramount. According to a report by the International Motion Control Association, the demand for high-precision motion systems is expected to grow at a CAGR of 8.5% through 2025. This growth is largely fueled by advancements in industries such as robotics, semiconductor manufacturing, and medical devices, where voice coil stages can deliver exceptional performance.

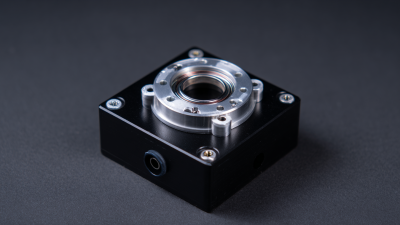

Key features of voice coil stages include high linearity, fast response times, and low hysteresis, making them ideal for applications requiring precise positioning. Performance metrics reveal that voice coil motors can achieve accelerations upwards of 200 g and a resolution down to nanometers, which is essential for tasks like laser machining and optical alignment.

Additionally, typical specifications for these systems indicate operational ranges of several millimeters to tens of millimeters, with load capacities that can accommodate both lightweight and more substantial payloads, thus enhancing their versatility across various applications. As industries continue to push for greater precision, voice coil stages are set to play a fundamental role in meeting these demanding requirements.

Voice coil stages (VCS) are becoming critical in various industries, particularly in robotics and medical devices. In robotics, VCS allow for unparalleled precision, essential for the development of humanoid robots that are expected to be mass-produced by 2025. By enabling high-resolution motion control, voice coil actuators facilitate smooth and accurate movements, which are crucial for tasks requiring dexterity and responsiveness. This technology not only enhances the performance of robotic systems but also contributes to their reliability and lifespan.

In the medical field, voice coil actuators offer significant advantages in surgical and diagnostic instruments. Their ability to provide precise motion without backlash or cogging allows for finer control in procedures where accuracy is paramount. As medical designs evolve, the integration of VCA technology ensures that devices are not only compact but also deliver high performance and efficiency.

**Tips:** When considering VCS for your projects, focus on the specific requirements of your application, such as load capacity and the precision needed. Additionally, keep abreast of technological advancements to ensure that you're leveraging the most efficient and effective solutions available in the market.

Voice coil stages are increasingly becoming a game changer in the realm of precision motion control, particularly when compared to traditional solutions. Unlike older systems that often rely on complex mechanical linkages or pneumatic actuators, voice coil stages utilize electromagnetic principles to provide direct linear motion, which enables finer control with reduced lag. This technology can achieve exceptionally high response speeds, typically in the range of millimeters per second, and positional accuracies up to a micron, making it ideal for applications requiring meticulous precision, such as laser cutting and semiconductor manufacturing.

In a comparative analysis, voice coil stages demonstrate several advantages over conventional motion control systems. Traditional solutions may involve backlash, hysteresis, and variable stiffness, which can compromise performance in high-resolution applications. Statistical data from recent industry reports indicate that voice coil actuators can reduce operational errors by as much as 30% when compared to their mechanical counterparts. Moreover, the compact design of voice coil stages allows for easy integration into existing systems, enhancing versatility without sacrificing performance. As industries increasingly demand more reliable and precise motion control, the shift towards voice coil technology is set to shape the future of engineering solutions significantly.

Voice coil technology is increasingly recognized as a game-changer in the field of motion control, particularly within precision applications. According to a report by MarketsandMarkets, the global motion control market is expected to reach $29.6 billion by 2026, with voice coil systems holding a significant share due to their ability to provide high-speed and accurate motion capabilities. These systems utilize electromagnetic forces to drive motion, allowing for rapid response times and reduced settling periods, which is essential in high-performance applications such as robotics, optics, and semiconductor manufacturing.

As industries continue to demand greater precision and speed, voice coil technology is set to play a pivotal role in the evolution of motion control systems. A study from Technavio suggests that advancements in voice coil actuators are expected to enhance their efficiency and reliability, catering to applications across medical devices, aerospace, and even automated guided vehicles (AGVs). The integration of advanced sensors and control algorithms with voice coil actuators promises to foster innovation, enabling smoother and more precise operations, thus pushing the boundaries of what is achievable in motion control.

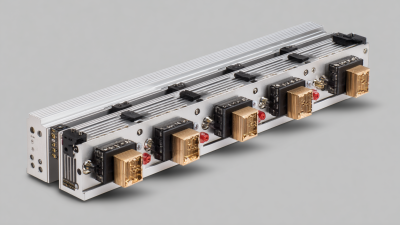

| Dimension | Value | Description |

|---|---|---|

| Max Load Capacity | 50 N | The maximum force the voice coil stage can handle. |

| Speed Range | 0 - 200 mm/s | The operational speed range for precise movements. |

| Positioning Accuracy | 1 µm | The minimum deviation from the target position. |

| Control Type | Closed-loop | Feedback control for enhanced precision and stability. |

| Typical Applications | Optics, Robotics | Common industries where voice coil stages are utilized. |

| Operation Environment | Cleanroom compatible | Design allows usage in controlled environments. |

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.