Call Today: 916-259-1868

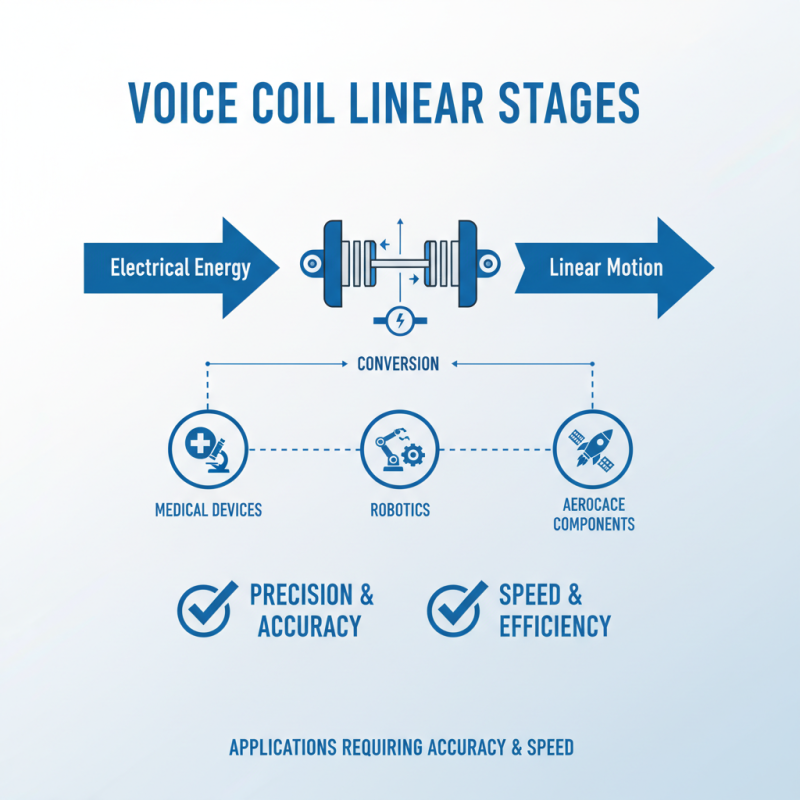

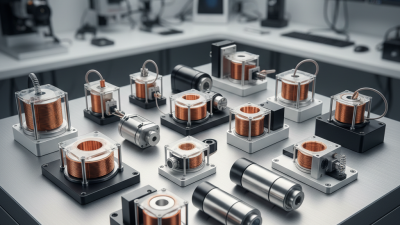

The voice coil linear stage is an innovative device with various applications. It is designed for precision movement in different industries. This technology excels in tasks requiring high accuracy and speed.

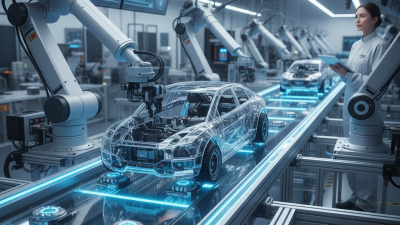

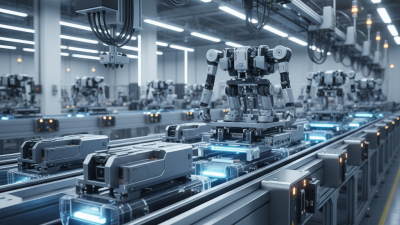

One notable application is in robotics. Voice coil linear stages help robots move with precision. They enable fast and reliable positioning in complex tasks. Medical devices also benefit from this technology. Procedures requiring accuracy are simplified, enhancing patient safety.

This technology is not without challenges. The initial costs can be high for implementation. Moreover, the maintenance of voice coil linear stages requires careful consideration. Despite these drawbacks, their advantages often outweigh the downsides. The benefits lead to significant advancements in automation and control systems.

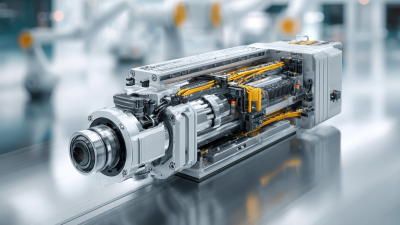

Voice coil linear stages are essential for many applications. They provide precise linear motion with a simple design. These stages use electromagnetic force to create movement, making them efficient and reliable. They are commonly found in robotics, automation, and medical devices. Their compact size allows for integration in tight spaces, which is crucial in many fields. The high accuracy of these systems helps in delivering consistent results.

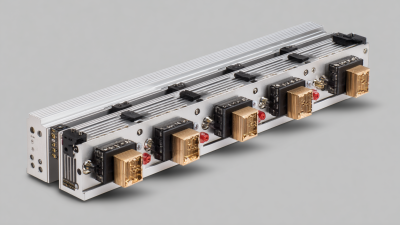

In terms of functionality, voice coil stages offer quick response times. They can accelerate and decelerate rapidly, enabling dynamic operations. This is particularly beneficial in applications like laser cutting or 3D printing. However, these systems may struggle with heavy loads. This limitation can impact performance in certain scenarios. Additionally, they often require precise control systems for optimal functioning. Sometimes, users may overlook the need for comprehensive calibration. This oversight can lead to unexpected inaccuracies in movement.

Users appreciate the ease of integration with existing systems. However, challenges in programming and maintenance can arise. Operators need a good understanding of the controls. Ensuring proper alignment is also critical for achieving desired outcomes. Despite these drawbacks, the advantages of voice coil linear stages often outweigh the potential issues. They remain a popular choice for many high-performance applications.

Voice coil linear stages are widely used in various industries for precision applications. These systems convert electrical energy into linear motion. This makes them ideal for tasks that require accuracy and speed. They can be found in medical devices, robotics, and even aerospace components.

In the medical field, for example, voice coil linear stages streamline processes like laser surgery. They allow for precise movements, which are crucial during delicate procedures. Additionally, in robotics, these stages enhance the functionality of robotic arms. They provide quick and accurate positioning for assembly and manufacturing tasks. Yet, challenges remain in optimizing their control systems and minimizing vibrations.

Aerospace applications also benefit from these linear stages. They play a key role in testing components under simulated conditions. However, the complexity of these systems can lead to issues. Engineers must carefully address limitations in performance and ensure reliability. Improvement in design and technology may offer more efficient solutions.

Voice coil linear stages offer significant advantages in precision motion control applications. The simplicity of their design allows for straightforward integration into various systems. These stages provide a high level of accuracy and repeatability, often achieving resolutions in the micrometer range. Reports indicate that voice coil systems can deliver positioning accuracy levels of 20 micrometers or better, making them suitable for high-tech industries, including semiconductor manufacturing and biomedical applications.

Another benefit is their rapid response time. Voice coil motors can accelerate quickly and adjust positions with minimal delay. This responsiveness enhances overall system efficiency. In fact, many engineers have noted a time reduction of up to 30% in cycle times compared to traditional systems. This is crucial in environments where speed is key to productivity. However, the setup can be complex. Proper calibration requires time and expertise. Mistakes in alignment might lead to suboptimal performance.

Another detail to consider is their operational range. While these stages excel in small movements, they may struggle with larger displacements. Some applications demand greater linear travel, which can exceed the capabilities of voice coil designs. Nevertheless, enhancements in technology and design are helping to bridge this gap. Still, potential users must weigh their specific needs against these limitations.

When selecting a voice coil linear stage, several factors must be kept in mind. The load capacity of the system is crucial. It influences the stage’s ability to perform under pressure. If the load is too heavy, the motion may become unstable. Additionally, consider the required speed and acceleration. Different applications have varying demands. High-speed operations need robust designs.

Precision is another vital aspect. The stage must maintain accuracy in positioning. This accuracy impacts results in delicate experiments or manufacturing processes. Users should also evaluate the stroke length based on their specific applications. Longer strokes can give more flexibility, but may introduce complications in control.

Integration with existing systems needs careful thought. The compatibility of electronics and control systems is essential. Moreover, installation space can't be overlooked. Limited space might restrict options. Lastly, monitoring and feedback mechanisms are important for real-time adjustments. Reflecting on these factors ensures that the chosen voice coil stage meets application needs effectively.

Voice coil linear stages are increasingly popular in various applications. These devices offer precise movement control, making them ideal for automation tasks. They are commonly used in robotics, medical devices, and testing equipment. Their simplicity and effectiveness are appealing. However, as applications grow, so do the challenges.

Future trends in voice coil linear stage technology focus on improved efficiency. Research is ongoing to enhance response times and reduce power consumption. These improvements could make the technology more accessible for different industries. Additionally, miniaturization is a key trend, allowing for smaller, more compact designs. This shift opens up new possibilities in tight spaces where traditional systems cannot fit.

Despite these trends, there are challenges to consider. The need for affordability is crucial. As demands grow, costs must also be managed. Companies may struggle with balancing quality and price. Long-term reliability is another concern. Striving for perfection can sometimes lead to compromises in durability. As the technology evolves, these factors will require careful reflection and innovation.

| Application Area | Advantages | Future Trend |

|---|---|---|

| Medical Devices | Highly precise positioning for surgical instruments | Integration with robotics for enhanced procedures |

| Material Handling | Responsive to changes in load and speed | Adoption of AI for optimized performance |

| Electronics Testing | Minimal settling time for fast testing cycles | Increased automation in testing processes |

| Optical Systems | Smooth linear motion for focusing and alignment | Miniaturization of components for compact designs |

| Semiconductor Manufacturing | Extreme precision in wafer handling | Advanced sensors for real-time adjustment |

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.