Call Today: 916-259-1868

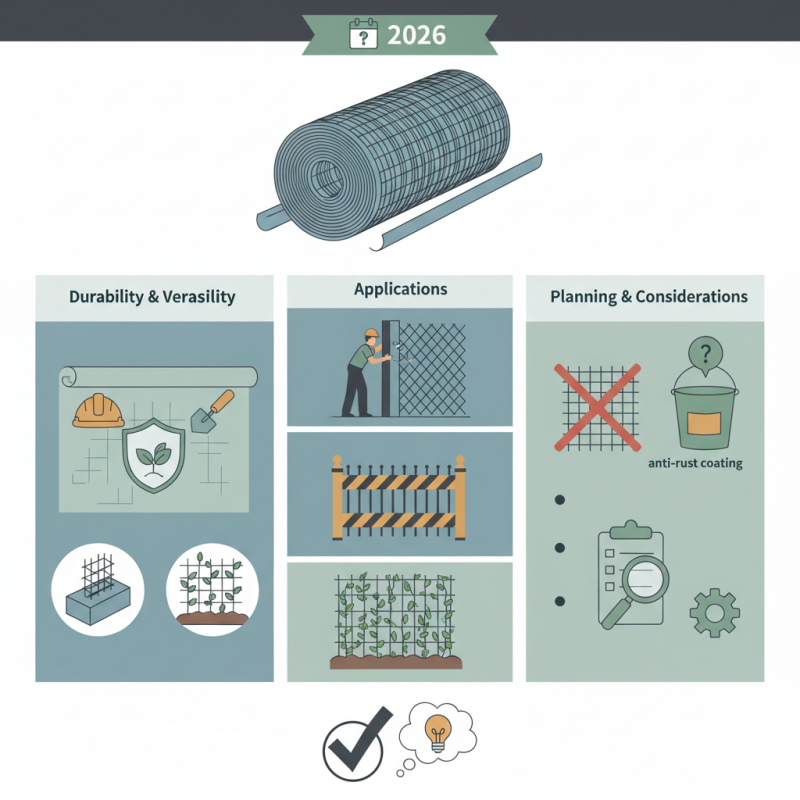

When planning a project that requires durability and versatility, consider using welded wire mesh. This material is made from high-quality steel wires, joined together through welding. It provides a strong framework for various applications, from construction to gardening.

welded wire mesh can serve multiple purposes. For instance, it can be used to reinforce concrete structures, create protective barriers, or support plants in your garden. The uniformity of welded wire mesh also adds an aesthetic touch. However, it isn’t always the best choice for every situation. In some cases, the mesh may not provide adequate support or may rust if not properly coated. It’s essential to evaluate your specific needs.

Ultimately, using welded wire mesh effectively requires planning. Understanding your project’s requirements is crucial. Be mindful of the potential shortcomings of this material, as not all projects will benefit from its use. Reflect on these details before proceeding.

Welded wire mesh is a versatile material used across various projects. It consists of steel wires joined by welding at intersections. This weld creates a strong grid structure. Various gauges and mesh sizes are available. You can select based on the intended application. For instance, a larger mesh may suit fencing, while smaller sizes work better for concrete reinforcement.

When using welded wire mesh, consider the material specifications. Steel is common, known for its durability and strength. Galvanization offers added protection against corrosion. This is crucial for outdoor projects where exposure to elements is a concern. Additionally, the mesh's wire diameter affects its strength and application. Thicker wires enhance structural integrity, yet they can be more challenging to handle.

Understanding how to cut and shape welded wire mesh can be tricky. Measuring accurately prevents waste and ensures precision. Mistakes can happen, like miscalculating sizes or not accounting for overlaps. It’s essential to reflect on these aspects in your planning phase to avoid frustrations during the installation process.

Welded wire mesh comes in various types, each serving specific project needs. For instance, standard welded wire mesh features square or rectangular openings. This type is commonly used in concrete reinforcement and flooring. Its strong structure supports heavy loads and enhances durability. A well-constructed slab benefits from this reliable material, but not all projects require such strength.

Another type is welded wire fencing, designed for security and animal enclosures. This mesh offers a lightweight yet robust solution for gardens or livestock areas. It is easy to install and provides excellent visibility. However, its protective qualities might not be sufficient for all pets. Sometimes, heavier gauge materials are necessary for larger animals or more aggressive situations.

Finally, decorative welded wire mesh adds a stylish touch to architectural designs. It can be used for partitions, fencing, or gates. While it looks appealing, its primary function is still to provide security. It’s crucial to ensure that the decorative features don’t compromise strength. Each type of welded wire mesh has distinct advantages and limitations. Understanding these can lead to better project outcomes.

Welded wire mesh is a versatile material in various projects. From gardening to home construction, its uses are numerous. One key aspect is cutting and shaping it effectively.

Before starting, gather the right tools. You will need heavy-duty wire cutters, a measuring tape, and gloves for safety. Measure the dimensions needed. Cutting the mesh can be tougher than expected. Ensure you secure it firmly before making any cuts. It’s essential to cut slowly and steadily to avoid pesky accidents. Although the mesh is strong, precision is crucial.

When installing welded wire mesh, proper techniques are essential for ensuring durability and effectiveness. Begin by measuring the area accurately. Cut the mesh to size before installation. Ensure the borders fit snugly without gaps. Use gloves during the process to avoid injuries from sharp edges.

Secure the mesh with reliable fasteners. Galvanized nails or wire ties work well. Ensure they are tightly fastened without over-stretching the mesh. A common mistake is applying too much tension, which can lead to unsightly buckling over time.

Consider the underlying surface before installation. Uneven ground can create potential issues later. Use a level tool to verify flatness. If you notice any serious imperfections, address them now. Not paying attention to details may lead to problems in structural integrity later on. Each step matters, and perfection isn’t always achievable. However, learning from mistakes during the installation process will help achieve better results in future projects.

Welded wire mesh is a versatile material, widely used in various construction and landscaping projects. However, to ensure its longevity, proper maintenance is essential. Regular inspections can help identify rust or damage early. Look for any signs of wear and tear. This can prevent larger, costlier issues down the line.

Cleaning the mesh is important, especially in harsh weather. Dust and grime can build up and lead to corrosion. A simple rinse with water can often do the trick. Occasionally, applying a protective coating can enhance durability. Keep in mind that neglecting maintenance may result in the mesh deteriorating faster than expected.

It’s crucial to consider the environment where the mesh is placed. Areas with heavy moisture or salty air can accelerate wear. Adjust your maintenance routine accordingly. In regions with heavy snowfall, consider off-season care as well. Taking the time to focus on these aspects can greatly extend the life of welded wire mesh structures. Proper care leads to better performance and satisfaction with your projects.

| Project Type | Welded Wire Mesh Size (inches) | Application | Maintenance Tips |

|---|---|---|---|

| Garden Fencing | 48 x 24 | Secure plant areas | Regularly check for rust; paint every 2 years |

| Concrete Reinforcement | 60 x 60 | Enhance strength of concrete | Inspect for bend and wear; clean before pouring concrete |

| Animal Caging | 36 x 36 | Contain livestock safely | Inspect joints and panels; replace damaged sections |

| Architectural Features | 48 x 48 | Decorative elements | Clean with mild soap; ensure structural integrity |

| Construction Fencing | 48 x 12 | Site safety barriers | Secure loose ends; check for stability |

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.