Call Today: 916-259-1868

The selection of the best linear rotary motor for your project can significantly impact the efficiency and performance of your machinery or automation systems. According to a recent report by the International Federation of Robotics, the demand for linear rotary motors has seen a remarkable increase, with an estimated annual growth rate of over 8% in the industrial automation sector. This trend underscores the importance of making informed decisions when choosing these components, as their effectiveness can affect not only product quality but also the overall operational costs.

When navigating the vast array of options available, understanding the key specifications and features that differentiate linear rotary motors is crucial. Factors such as torque, speed, size, and thermal management can profoundly influence the motor's functionality in your application. A study published in the Journal of Mechanical Engineering indicates that improper selection can lead to inefficiencies and increased maintenance costs, highlighting the necessity for a thorough evaluation process. This article aims to equip you with the top 10 tips for choosing the best linear rotary motor that aligns with your project's specific requirements, ensuring optimal performance and reliability.

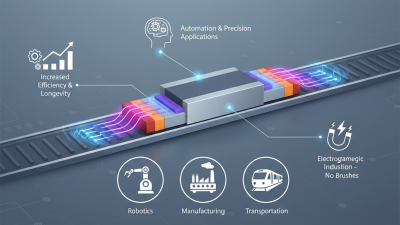

Linear rotary motors are innovative devices that combine the principles of linear and rotary motion in a single system. These motors allow for precise control in applications ranging from robotics to automation in manufacturing. Understanding their unique functionalities is essential when integrating them into your projects. The versatility of linear rotary motors makes them suitable for tasks that require both linear movement and rotational actions, such as in CNC machines, conveyor systems, and advanced robotics.

When considering the best linear rotary motor for your project, one of the essential tips is to assess the force and torque requirements you need. This involves evaluating the load the motor will handle and the speed at which you require the movement. It's crucial to ensure that the motor you select can provide adequate performance without overloading, which can lead to durability issues.

Another vital tip is to pay attention to the motor’s control system compatibility. Ensure that the motor can seamlessly integrate with existing control systems and software used in your project. This facilitates smoother operation and easier adjustments to the performance of the motor. By focusing on these aspects, you can effectively enhance your project's efficiency and performance while utilizing the unique benefits of linear rotary motors.

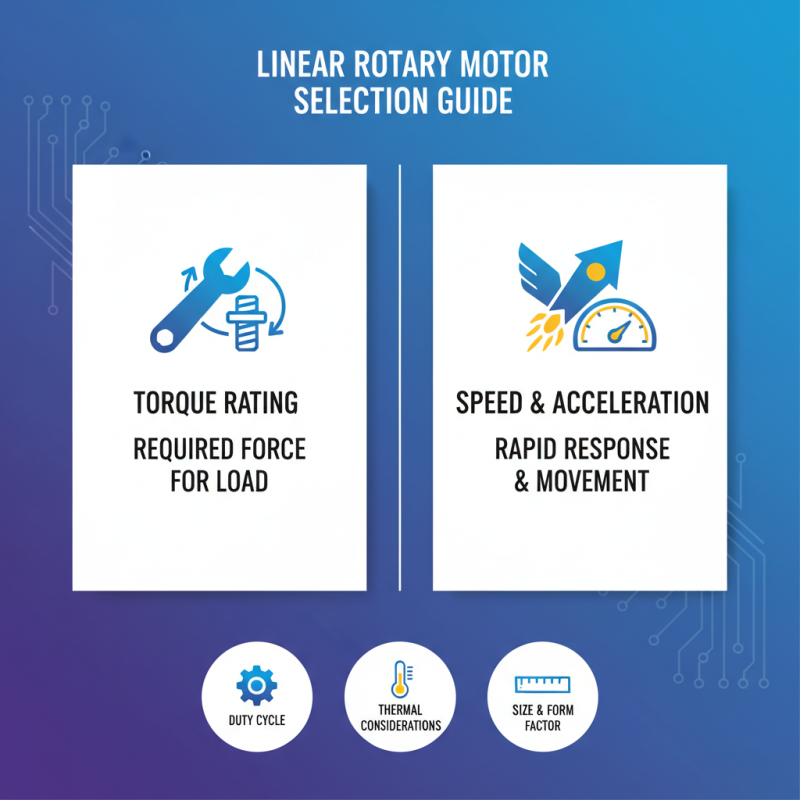

When selecting a linear rotary motor for your project, it's crucial to focus on key specifications that directly impact performance and suitability for your specific application. One of the primary considerations is the motor's torque rating. Ensuring that the motor can deliver the required torque under varying operational conditions is essential for achieving optimal performance. Additionally, understanding the motor's speed characteristics, including maximum speed and acceleration capabilities, is vital for applications that demand rapid operational response.

Another important specification to consider is the motor's interface options. Different projects may require compatibility with various control systems, so it's essential to evaluate the available communication protocols and input formats. This ensures a seamless integration into your existing system. Furthermore, pay attention to the motor's physical dimensions and mounting options, as these factors will significantly influence installation and operational efficiency.

When choosing a motor, always assess the thermal performance metrics as well. Motors that operate efficiently under thermal stress will exhibit enhanced reliability and longevity, reducing maintenance needs and downtime. Investing time in understanding these specifications will help in selecting a linear rotary motor that aligns perfectly with your project's unique requirements.

When selecting a linear rotary motor for your project, assessing

the power and torque requirements is crucial for optimal performance. Understanding the specific needs of your application ensures that the motor can handle the desired load while operating efficiently. Begin by analyzing the maximum load and speed your project demands. This involves calculating the necessary torque required to move the load at the specified speed. Remember that torque can vary significantly based on the load type and motion dynamics, so accurate calculations are vital.

One tip for gauging motor suitability is to consider the operating environment. Factors such as temperature, humidity, and potential contaminants can affect motor performance. It’s essential to choose a motor specifically designed to withstand the environmental challenges your application may face. Additionally, think about the power supply available; ensuring compatibility can prevent underperformance or motor damage.

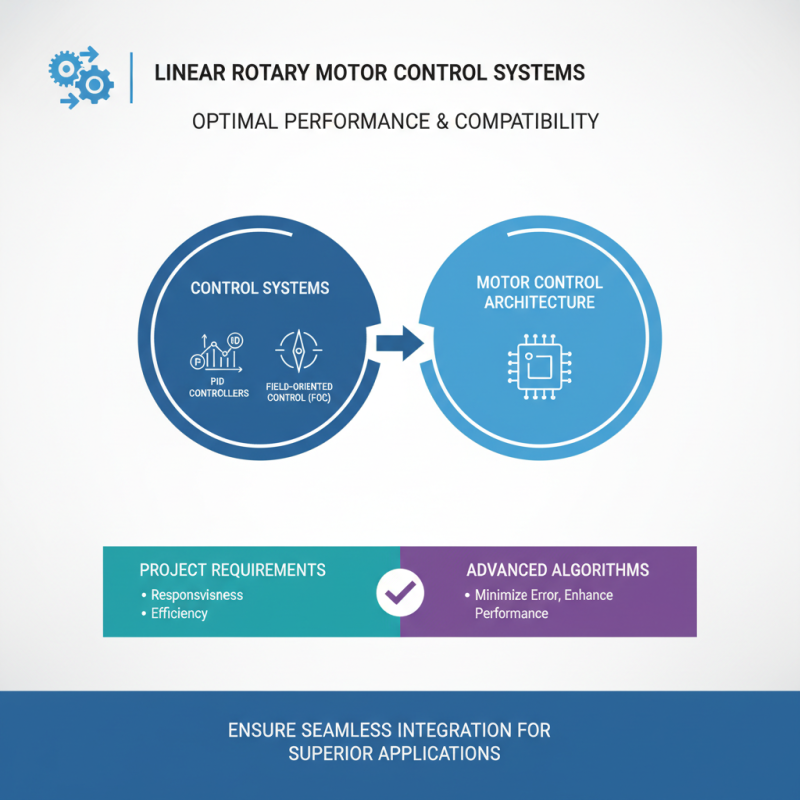

When selecting a linear rotary motor for your project, evaluating the control systems and ensuring compatibility is crucial. A deep understanding of the motor’s control architecture can significantly affect the performance and efficiency of your application. Most modern linear rotary motors are compatible with a variety of control systems, such as PID controllers and field-oriented control (FOC) systems, which help in precisely managing the motor’s operation. It is essential to determine which control system best aligns with your project's requirements; for instance, applications demanding high responsiveness and precision may benefit from advanced control algorithms that minimize error and enhance performance.

In addition to the control system, compatibility with existing hardware and software is another vital factor. This includes checking if the motor can interface seamlessly with other components such as drives, sensors, and controllers, potentially leveraging standard communication protocols like CANopen or EtherCAT. Ensuring robust data exchange and ease of integration will not only streamline your development process but also enhance the overall functionality of your project. Conducting thorough compatibility tests will help mitigate risks related to system integration, making sure that all components work harmoniously together.

When selecting the best linear rotary motor for your project, one of the pivotal factors to consider is the balance between costs and performance. Investing in a high-quality motor often leads to greater efficiency, longer lifespan, and enhanced reliability. However, it is essential to understand the specific performance requirements of your application to avoid overspending on features that may be unnecessary. A detailed cost analysis should include not only the purchase price but also potential maintenance costs and energy consumption over time.

One tip for making an informed decision is to prioritize your project’s needs. List the essential features that your motor must have, such as torque, speed, and precision. This approach enables you to focus on quality without getting sidetracked by extravagant specifications that may inflate your budget. Additionally, consulting with industry experts or utilizing product reviews can provide valuable insights into the performance and cost-effectiveness of various motor options, ensuring that you make a well-rounded choice for your project.

Another important aspect to consider is the long-term implications of your motor choice. Cheaper options might seem tempting, but they can end up costing more due to frequent replacements or repairs. Evaluating the total cost of ownership will help in identifying motors that offer the best value while still meeting performance standards. By staying aligned with your project’s objectives and carefully analyzing costs and performance, you'll be in a better position to select a linear rotary motor that meets your needs without compromising on quality.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.