Call Today: 916-259-1868

The 2026 landscape of rotary voice coil actuators is evolving rapidly. Innovations in design and function are shaping industries. These actuators offer precise motion control and are becoming vital in various applications.

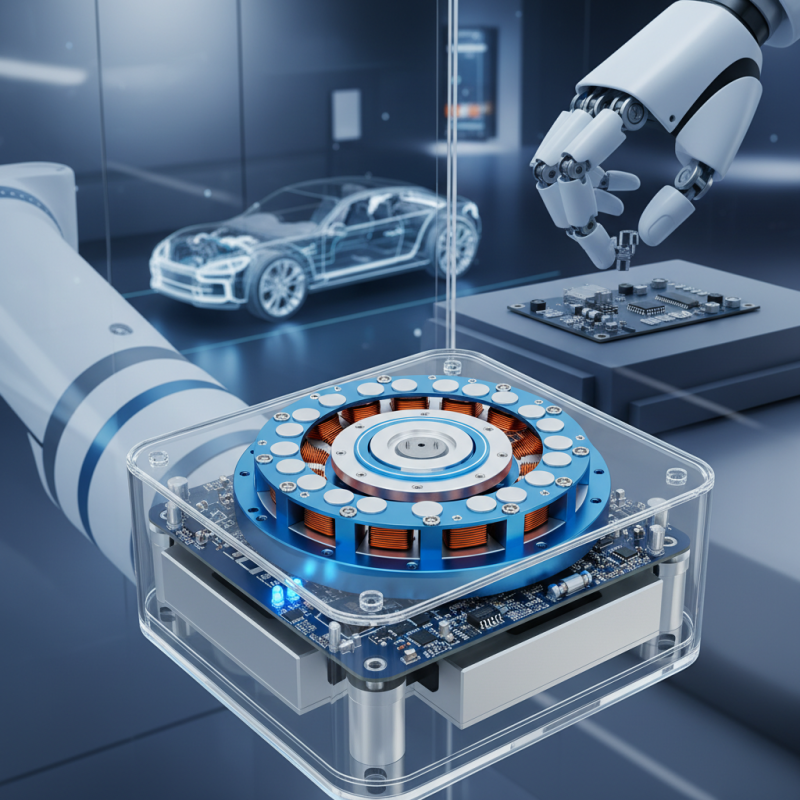

In automotive technology, rotary voice coil actuators enhance performance in electric vehicles. They improve steering systems and increase efficiency. In robotics, they enable precise movements, allowing robots to perform delicate tasks. However, challenges remain, especially in integrating these devices seamlessly into existing systems.

As industries adopt new technologies, the performance and reliability of rotary voice coil actuators must be closely examined. The quest for improvement is ongoing, as each innovation presents unforeseen obstacles. Reflecting on these advancements can lead to better solutions and understanding of their impact on our world.

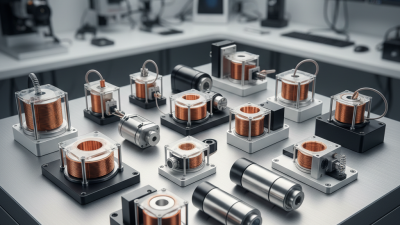

The design landscape for rotary voice coil actuators in 2026 is evolving rapidly. New concepts focus on improving efficiency and precision. Lightweight materials are gaining traction, allowing for better performance without adding bulk. Innovations in magnet configurations promise enhanced force output. Yet, the challenge remains. How to balance power and size effectively?

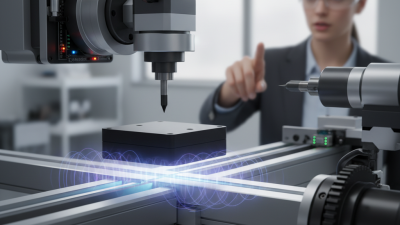

Incorporating advanced sensors into actuators is one innovative idea. This allows for real-time feedback and adjustments during operation. The integration of smart technologies is a trend worth noting. However, this also leads to increased complexity in design. Striking the right balance between simplicity and functionality will require careful thought.

Modular designs are being explored as well. This allows for customization based on user needs. While flexibility is a benefit, it can also complicate manufacturing processes. Each design phase necessitates a reevaluation of goals and practical application. Innovations are exciting, yet they invite the need for ongoing reflection and improvement. The path ahead is filled with potential, yet it will not be without its hurdles.

Rotary voice coil actuators (RVCAs) are becoming essential in various industries. Their ability to provide precise motion control makes them valuable in robotic applications. In surgical robots, RVCAs allow for fine manipulations during procedures, enhancing both accuracy and safety. The compact design of these actuators fits well into limited spaces, often required in medical instruments.

Another significant application is in aerospace. RVCAs are used for flight control surfaces, where rapid response time and reliability are critical. They can adapt to changing conditions, but their implementation does require careful calibration. In manufacturing, RVCAs contribute to automation, enabling faster assembly lines. However, integrating these systems is not always straightforward, as coordination with existing equipment can pose challenges.

The automotive sector also benefits from RVCAs. They facilitate advanced features in vehicles, like adaptive steering systems. Unfortunately, there can be a steep learning curve for engineers. Understanding how to optimize these systems can take time. Moreover, with increasing demands for efficiency, there may be pressure to rush the development process. This can lead to oversights that impact overall performance.

Recent advancements in materials for rotary voice coil actuators are transforming the industry. Engineers are exploring novel composites that enhance performance and efficiency. These materials improve thermal stability, allowing actuators to operate at higher speeds without overheating. Reports suggest that actuator reliability can increase by up to 30% with better materials.

The use of lightweight alloys in voice coil designs is becoming more common. This reduces the overall weight while maintaining strength. As a result, systems become more responsive, improving user experiences in various applications. For instance, automation and robotics sectors could benefit from these innovations, driving efficiency. Data from market analysis indicates that the global demand for advanced actuators is projected to grow by 15% annually through 2026.

However, challenges persist. Manufacturers often face difficulties in sourcing high-quality materials. Not all innovations yield significant performance boosts. It’s crucial to carefully evaluate material choices to avoid overestimations. Some advancements may not justify their cost, leading to hesitation in adoption. The industry's future hinges on overcoming these hurdles while embracing breakthroughs in material science.

The integration of smart technologies into rotary voice coil actuators is transforming the landscape of various industries. These actuators are now more responsive and efficient. They can adapt to real-time environmental changes. This capability is particularly crucial in automation systems. Smart sensors enhance their performance, allowing for precise adjustments.

Tips: When selecting a rotary voice coil actuator, consider its load capacity and response time. The right choice can significantly impact your project’s success.

However, implementing smart technologies can present challenges. The initial integration may require more resources. There is a learning curve for engineers. Ensuring compatibility with existing systems can be tricky. Attention to detail is essential to avoid costly errors.

Incorporating advanced algorithms can improve actuator functionalities. This leads to better control and enhanced performance. Yet, developers must be mindful of over-engineering. Keeping solutions simple can often yield better results. Simplicity fosters reliability and ease of use. Always balance innovation with practical application in mind.

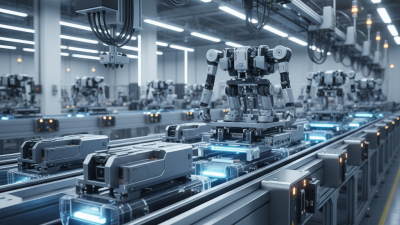

The rotary voice coil actuator is set to evolve significantly by 2026. New innovations will push the boundaries of precision and efficiency. Areas such as robotics and automation will benefit the most. These advancements will lead to smoother operation and faster response times. Emerging technologies will integrate with AI, enhancing overall functionality.

Some expect miniaturization to be a key trend. Smaller actuators can fit into compact devices. This could improve applications in medical devices and drones. However, challenges remain in maintaining performance while reducing size. It is crucial to find a balance.

Tips: Always consider the materials used. Lightweight and durable materials can lead to significant improvements. Understand that integration with existing technologies can be complex. Research and testing are vital for success in this evolving field. Remaining adaptable to change will pay off as new needs arise.

| Innovation | Application Area | Predicted Impact | Development Trend |

|---|---|---|---|

| High Precision Control Mechanisms | Robotics | Enhanced accuracy in motion control | Increasing integration with AI |

| Miniaturization Techniques | Consumer Electronics | Smaller and lighter designs | Focus on portable devices |

| Energy Efficient Models | Aerospace | Reduced power consumption | Sustainability in design |

| Smart Actuator Systems | Medical Devices | Improved performance monitoring | Increased data analytics integration |

| Modular Design | Industrial Automation | Flexibility in system configurations | Customizable solutions for various needs |

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.