Call Today: 916-259-1868

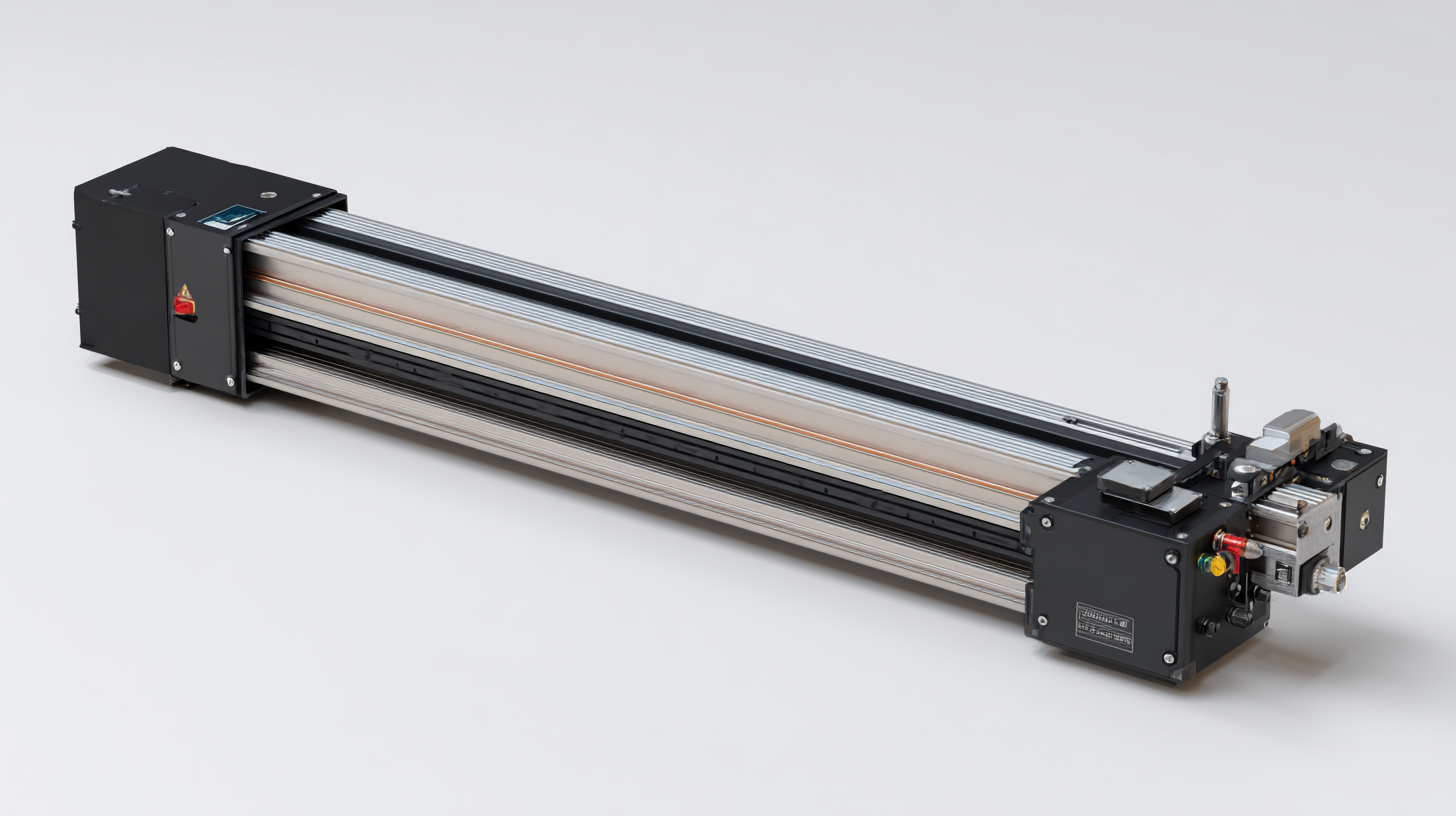

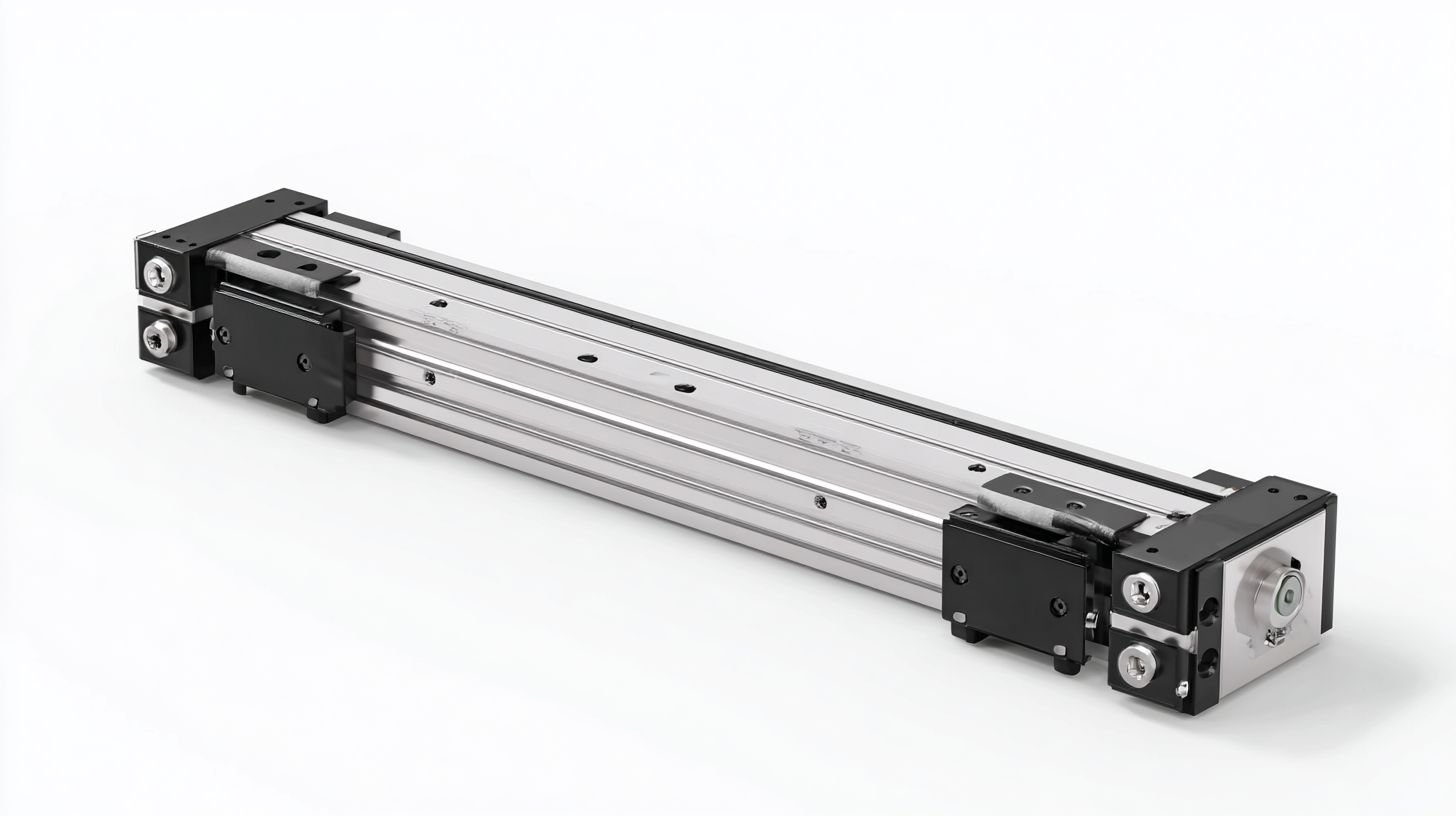

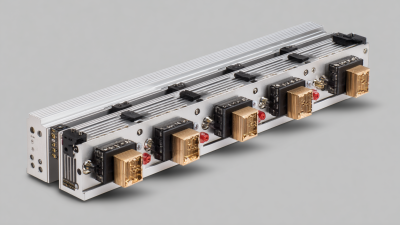

In the ever-evolving landscape of industrial technology, flat linear motors have emerged as a pivotal innovation, setting new standards for performance and efficiency. As industries strive for greater precision and speed, these motors are not just enhancing operational capabilities but are also redefining the fundamentals of automation and machinery design. The versatility of flat linear motors allows them to be integrated seamlessly into various applications, from advanced manufacturing processes to robotics and transportation systems.

This article delves into the top five innovations in flat linear motors anticipated for 2025. These breakthroughs promise to revolutionize industry by providing solutions that are faster, more efficient, and increasingly reliable. As we explore these advancements, we will highlight how flat linear motors are pushing the boundaries of what's possible, fostering a new era of smart manufacturing and automation. With their unique characteristics, flat linear motors are poised to become indispensable tools in the reimagining of industrial workflows, ultimately leading to enhanced productivity and performance across sectors.

As industries push towards smarter and more efficient systems, flat linear motors have emerged as a pivotal technology in manufacturing. These motors, known for their compact design and exceptional efficiency, play an essential role in the development of automated systems and robotics. According to a recent report, the global market for linear motors is projected to grow by 20% annually, highlighting the increasing reliance on this technology to streamline processes and reduce energy consumption.

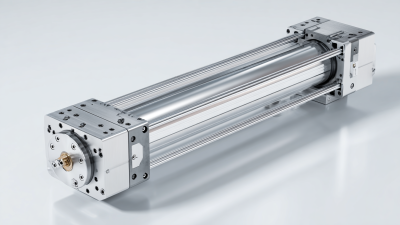

Flat linear motors are particularly advantageous in applications requiring precision and speed. With their ability to provide direct linear motion, they eliminate the need for traditional mechanical linkages, resulting in a cleaner and more efficient setup. A research study indicates that integrating flat linear motors into assembly lines can improve production rates by up to 30%, while also reducing maintenance costs. This data underscores the transformative potential of these motors in creating agile manufacturing systems that adapt quickly to changing demands.

As industries continue to prioritize sustainability and energy efficiency, the innovative designs of flat linear motors are paving the way for a smarter future. Leveraging their small size and inherent efficiency, they contribute to the development of energy-efficient manufacturing solutions that significantly lower operational costs while enhancing performance. Consequently, the industry is witnessing a surge in the adoption of these motors, marking a significant shift towards a more efficient manufacturing landscape.

This bar chart illustrates the projected efficiency improvements in manufacturing processes driven by the top 5 innovations in flat linear motors by 2025. The data highlights the expected percentage increase in system efficiency, showcasing how these innovations are set to transform industry operations.

Flat linear motors are emerging as a pivotal innovation in various industries, significantly contributing to environmental sustainability. According to a report by MarketsandMarkets, the global flat linear motor market is expected to grow from USD 2.1 billion in 2022 to USD 3.5 billion by 2026, largely driven by their efficiency and reduced energy consumption. These motors, by eliminating the need for traditional rotational components, not only enhance operational efficiency but also lower the carbon footprint associated with production and transportation.

Moreover, flat linear motors generate less waste heat compared to conventional drive systems, translating to lower cooling requirements and extended equipment lifespan. A study by the International Energy Agency highlights that energy-efficient motors can reduce energy consumption in manufacturing by up to 30%. This reduction is critical as industries seek solutions to meet increasingly stringent environmental regulations. By adopting flat linear motors, companies can achieve significant energy savings while also aligning with the global push for greener technologies, ultimately fostering a more sustainable industrial landscape.

The integration of advanced flat linear motor designs is reshaping various industries by enhancing precision engineering and performance. Recent reports from industry leaders indicate that these innovations can improve efficiency by up to 30% compared to traditional motor technologies. With the ability to provide instantaneous torque and high-speed operation, flat linear motors are becoming essential in applications such as robotics, semiconductor manufacturing, and transportation systems. This shift is expected to produce a 15% reduction in energy consumption, showcasing their role in sustainable manufacturing practices.

The integration of advanced flat linear motor designs is reshaping various industries by enhancing precision engineering and performance. Recent reports from industry leaders indicate that these innovations can improve efficiency by up to 30% compared to traditional motor technologies. With the ability to provide instantaneous torque and high-speed operation, flat linear motors are becoming essential in applications such as robotics, semiconductor manufacturing, and transportation systems. This shift is expected to produce a 15% reduction in energy consumption, showcasing their role in sustainable manufacturing practices.

Tips for optimizing the performance of flat linear motors include the importance of proper alignment during installation, which can significantly impact accuracy. Additionally, regular maintenance and monitoring of thermal performance can prevent overheating and extend the lifespan of these motors. Manufacturers should also consider investing in software solutions that enhance control algorithms, allowing for more precise movements and better integration with sophisticated automated systems.

The advancements in flat linear motors are not just about speed; enhanced designs have made them more compact and lightweight, providing industry professionals with the versatility to adapt to rapidly changing market demands. As research continues, expect further innovations that will push the boundaries of what flat linear motors can achieve in precision engineering.

The implementation of flat linear motors is transforming various industries by delivering unparalleled cost-effectiveness. These motors eliminate the need for complex mechanical components, reducing maintenance costs and downtime. The streamlined design also means lower energy consumption, making them an environmentally friendly choice with long-term financial benefits. Businesses leveraging this technology are not only seeing immediate savings but are also enhancing their operational efficiency.

Tip: When considering the switch to flat linear motor technology, conduct a thorough cost-benefit analysis to assess potential savings in energy and maintenance.

Additionally, the scalability of flat linear motors allows companies to adapt and innovate their processes without hefty investments. This adaptability supports a swift return on investment, a crucial aspect for industries aiming to remain competitive. The reduced noise and vibration also mean a more pleasant working environment, which can boost productivity levels.

Tip: Collaborate with experienced manufacturers to explore customized solutions that fit your specific operational needs, ensuring maximum efficiency and cost savings.

The rise of flat linear motors is transforming various industries by providing a competitive edge through enhanced efficiency and precision.

For instance, the automotive sector is increasingly integrating flat linear motors into assembly lines, enabling faster and more accurate placement of components.

According to a report by MarketsandMarkets, the global market for linear motors is expected to reach $5.29 billion by 2025, driven primarily by innovations in flat linear motor technology.

This growth highlights the industry's shift towards automation, where manufacturers seek to reduce operational costs and improve product quality.

In the logistics and material handling industry, flat linear motors facilitate streamlined operations through their ability to operate without mechanical wear.

A study from ResearchAndMarkets has indicated that the adoption of these motors can increase the speed of automated guided vehicles (AGVs) by up to 20%, significantly enhancing throughput in warehouses.

Furthermore, the semiconductor manufacturing sector benefits from the precision movement that flat linear motors offer, optimizing the processing times of delicate components, and contributing to higher yields.

These advancements are crucial as industries continue to seek innovative solutions to meet growing consumer demands and tighter production schedules.

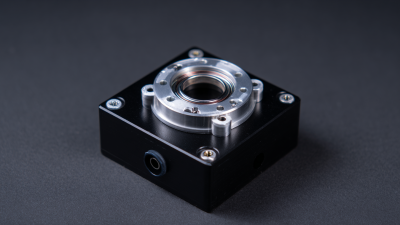

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.