Call Today: 916-259-1868

In the rapidly evolving landscape of automation and robotics, the significance of small linear motors cannot be overstated. These compact yet powerful devices play a crucial role in driving precision and efficiency across a range of applications, from medical devices to industrial machinery. According to a recent report by Markets and Markets, the global market for linear motors is projected to grow from $2.3 billion in 2022 to $3.6 billion by 2027, underscoring the strong demand for innovative motor solutions. As more industries recognize the advantages of small linear motors—such as their high speed and reliability—the need for selecting the right model for specific projects becomes increasingly paramount.

Expert in motion control technology, Dr. Emily Zhang, emphasizes, "The future of engineering lies in efficient motion solutions, with small linear motors at the forefront of this revolution." Her insights highlight not only the technological advancements in motor design but also the increasing demand for versatile applications. In this context, understanding the various types of small linear motors and their respective benefits is essential for engineers and developers striving for excellence in their projects. This article will explore the top 10 small linear motors you should consider, ensuring you make informed decisions that align with your project requirements and objectives.

Small linear motors are becoming increasingly vital in various applications, ranging from robotics to precision manufacturing. According to a recent report by MarketsandMarkets, the global linear motor market is projected to grow from USD 5.53 billion in 2020 to USD 8.71 billion by 2025, reflecting a compound annual growth rate (CAGR) of 9.3%. This growth is driven by the demand for automation across industries that require efficient and precise motion control.

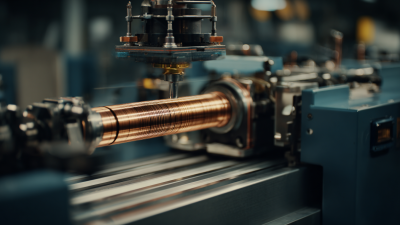

One of the key advantages of small linear motors is their ability to provide direct linear motion without the need for mechanical conversion, leading to increased efficiency and reduced wear. Their applications span across sectors such as medical equipment, where they are used in devices like syringe pumps, and in CNC machinery, where precise positioning is crucial. Research by Technavio highlights that the adoption of small linear motors in the manufacturing sector is expected to rise because of their reliability and the growing trend towards miniaturization in electronic devices. As these motors become more sophisticated, incorporating features like smart connectivity and integrated feedback systems, they are set to play an essential role in the future of automation and robotics.

This chart represents the maximum thrust (in Newtons) of the top 10 small linear motors suitable for various projects. The data reflects the performance of these motors, highlighting their potential applications in robotics, automation, and other engineering fields.

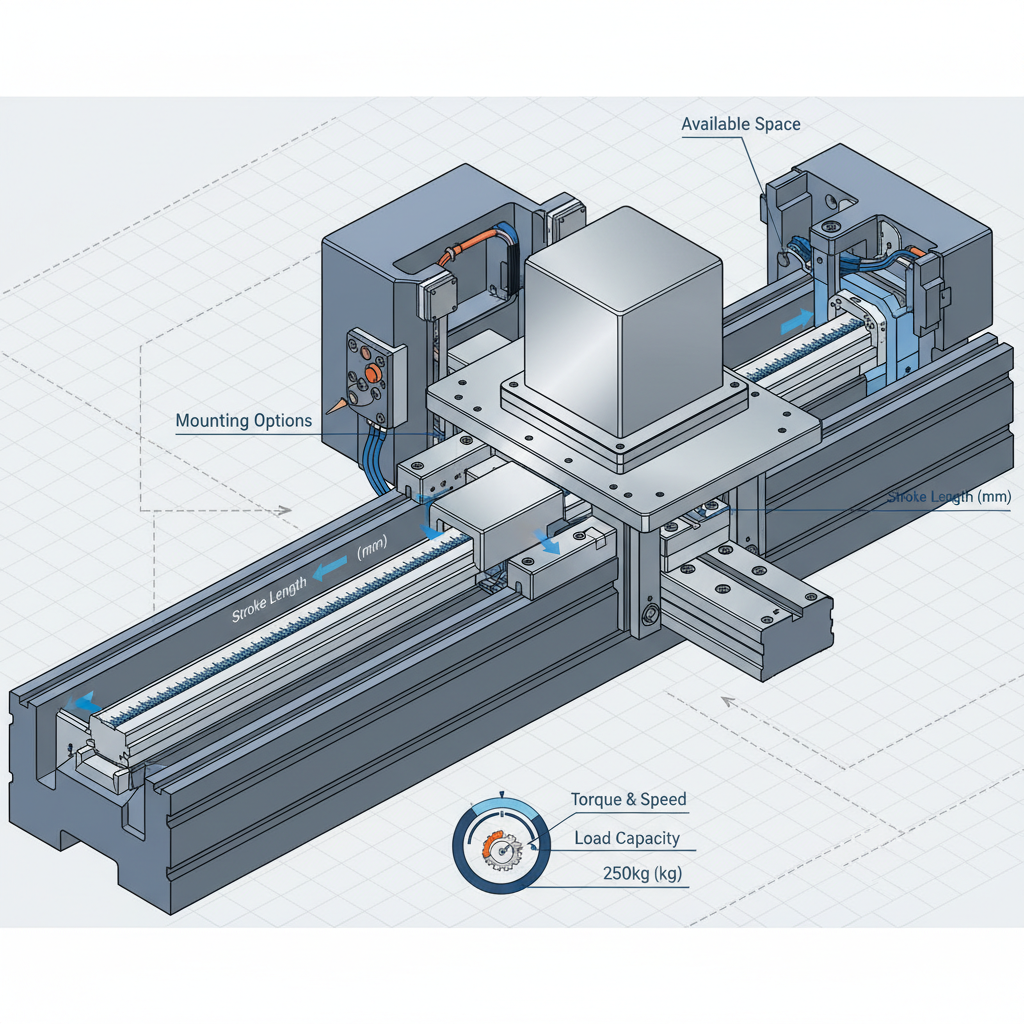

When selecting small linear motors for your projects, understanding the key factors involved in their performance is crucial. One of the primary considerations is the motor's load capacity. According to a report by the International Electromechanical Alliance, small linear motors typically exhibit load capabilities ranging from a few grams to several kilograms, influencing the type of application they are suitable for. This specification helps in selecting the right motor to achieve optimal performance without compromising the application’s integrity.

Another significant factor is the speed and stroke length. The linear motor's speed can affect the automation process, and as per the 2022 Linear Motion Technologies report, many small linear motors provide speeds of up to 300 mm/s with customizable stroke lengths that can vary between 10 mm to over 500 mm. Understanding the correlation between speed and stroke is essential for tasks requiring precision and efficiency.

**Tips:** When determining which motor to use, consider the application environment. For example, if the motor will operate in a high-temperature setting, ensure you select one rated for such conditions. Additionally, always refer to the manufacturer's data sheets for specifics on power consumption and cooling requirements to prevent overheating during prolonged use.

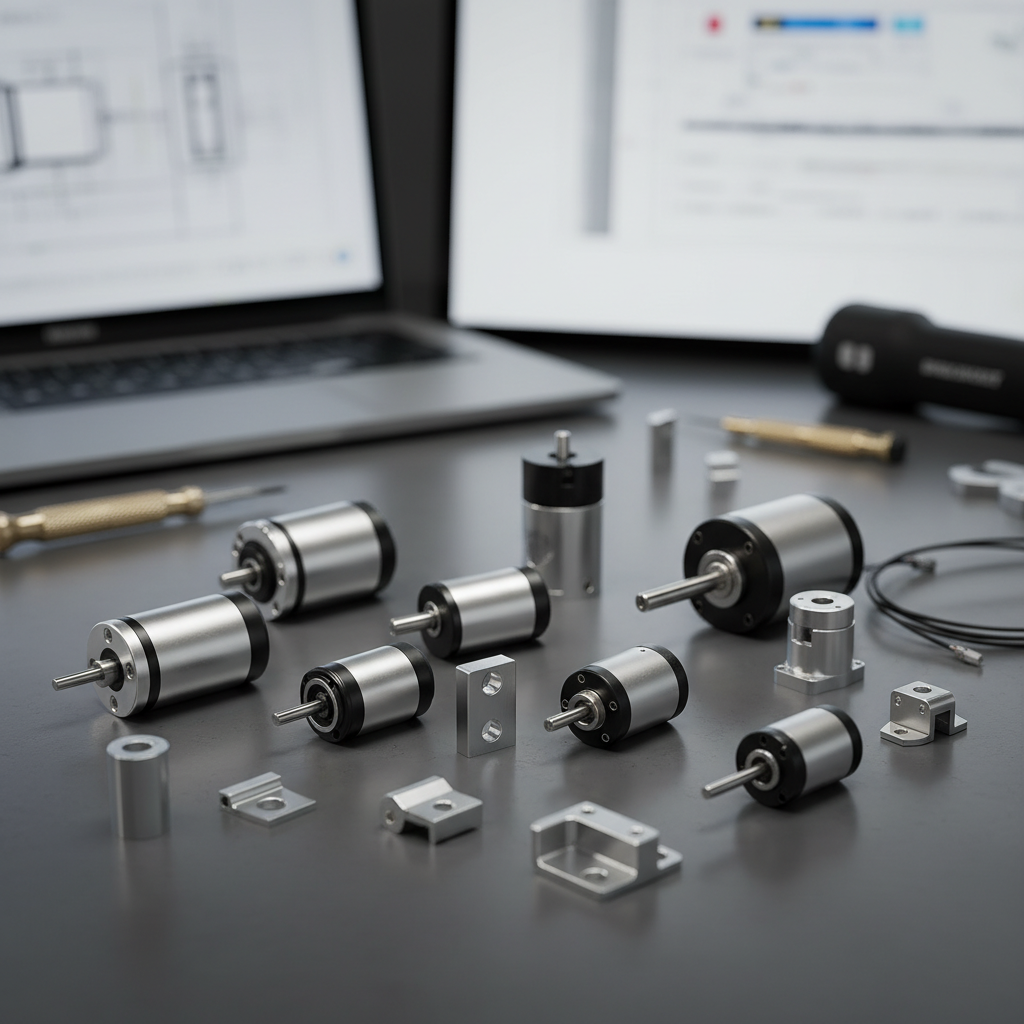

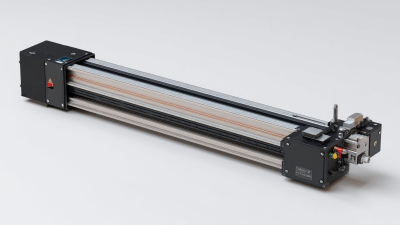

When working on your projects, finding the right small linear motor can significantly enhance functionality and efficiency. With various options available, it’s crucial to choose motors that cater to your specific needs, whether for hobby robotics, CNC machines, or automated systems. These small linear motors offer precision and reliability, making them ideal for a range of applications.

Tips: Always evaluate the specifications of each motor, including stroke length, force output, and speed. Consider the operating environment and whether your projects require a waterproof or low-noise motor. Additionally, exploring nano and micro motor options can lead to innovative solutions for compact designs.

When selecting a motor, think about your future project needs as well. Investing in motors that allow for easy customization and scalability can save you time and resources down the line. Compatibility with pre-existing components also plays a vital role in ensuring a smooth integration process. By taking these factors into account, you'll be well-equipped to make informed decisions that enhance your project's success.

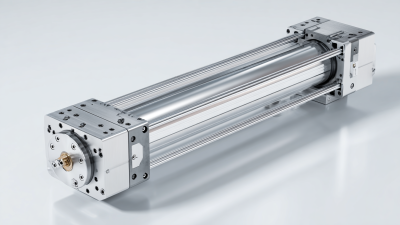

When selecting a small linear motor for your project, it's essential to conduct a thorough comparative analysis of specifications. Key factors to consider include the motor’s load capacity, speed range, and precision. For instance, motors with higher force ratings typically provide better performance for demanding applications, while those with refined speed controls are ideal for tasks requiring delicate movements. Additionally, evaluate the motor's power consumption, as energy efficiency can significantly impact long-term operational costs.

Tip: Look for motors that offer customizable features. Many manufacturers provide options to modify parameters such as stroke length and mounting configurations. Tailoring these specifications to your requirements ensures optimal compatibility with your project, ultimately enhancing performance and reliability.

Another crucial aspect to examine is the motor's thermal management and durability. Your chosen motor should not only perform well under standard conditions but also withstand environmental fluctuations. Pay attention to materials used in construction, as high-quality components can lead to greater longevity and better performance over time.

Tip: Stay informed about the latest developments in motor technology. Advances in materials and control systems can provide innovative solutions to enhance your project's effectiveness while potentially reducing costs.

When integrating linear motors into your designs, planning for precise motion control is paramount. Start by defining the required stroke length and load capacity for your application. Selecting a motor that not only meets these specifications but also provides the necessary torque and speed is crucial. Additionally, consider the linear motor's mounting options and available space within your design, as this will impact the ease of installation and overall performance.

Another best practice involves ensuring compatibility with control systems. Linear motors often require specific drivers that match their characteristics. Make sure to choose a controller that allows for smooth operation and can handle the feedback mechanism needed for closed-loop control. Moreover, cable management should not be overlooked; using flexible cables and proper routing techniques will minimize wear and contribute to the longevity of both the motor and the overall system. By taking these considerations into account, you can enhance the reliability and efficiency of your project with linear motors.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.