Call Today: 916-259-1868

In the rapidly evolving landscape of automation and robotics, the demand for high-performance linear motor controllers is surging. According to a recent market report by Research and Markets, the global linear motor market is projected to reach USD 4.96 billion by 2026, growing at a CAGR of 9.3% from 2021. This growth underscores the critical role that linear motor controllers play in optimizing motion control systems across various industries, from manufacturing to aerospace.

As we look ahead to 2025, selecting the right linear motor controller for your project becomes paramount. These devices not only enhance precision and speed but also improve overall energy efficiency, which is a key consideration in today’s eco-conscious manufacturing environments.

Industry experts suggest that incorporating advanced linear motor controllers can lead to significant cost savings and productivity gains, reinforcing their necessity for modern engineering applications.

In this guide, we will explore the top 10 linear motor controllers that you must consider for your next project. By leveraging cutting-edge technology and innovative features, these controllers will help you meet the demands of increasingly complex automation tasks while ensuring reliability and performance.

Embrace the future of motion control and stay ahead in your projects by investing in the best linear motor controllers available in 2025.

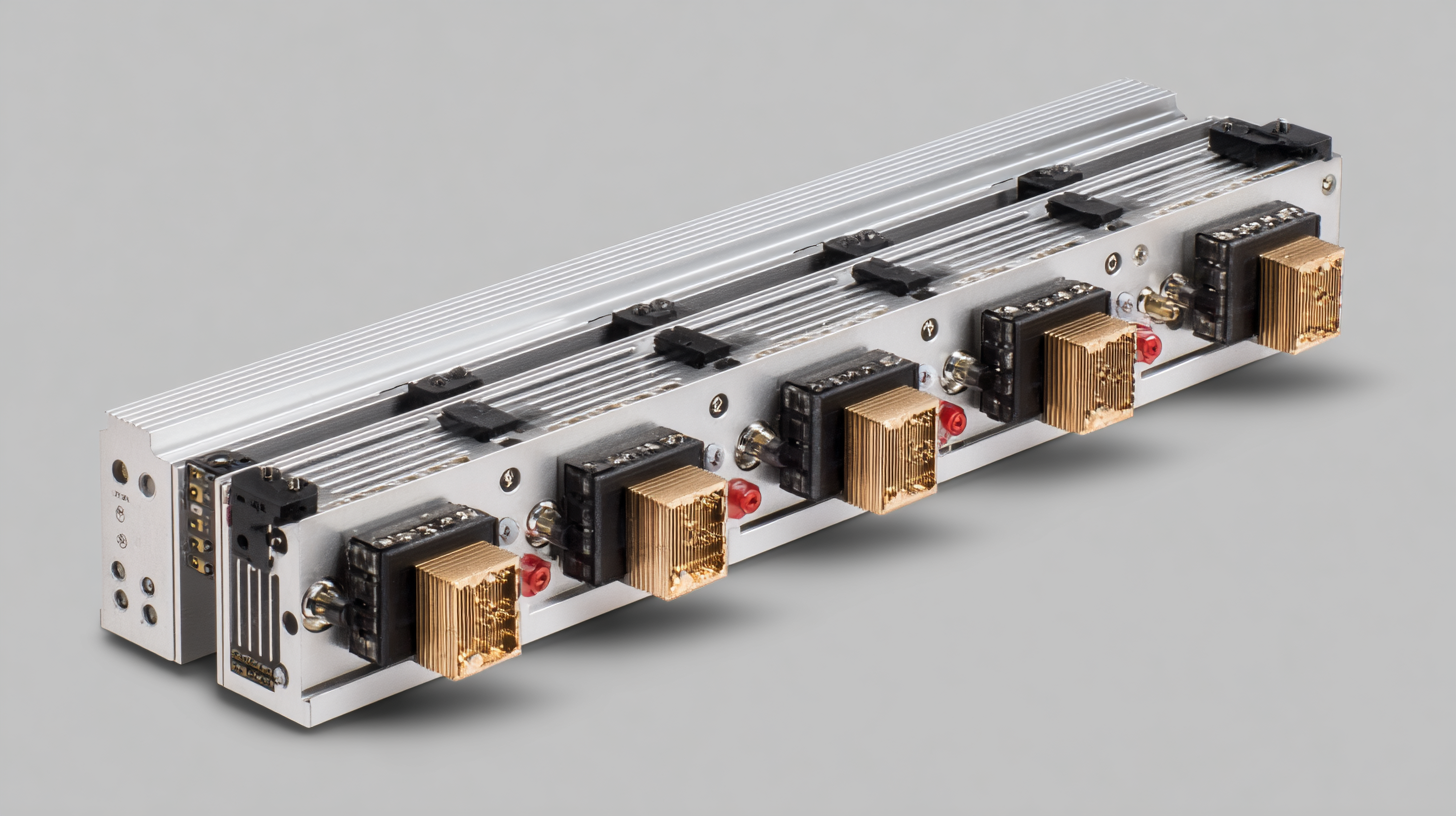

When selecting linear motor controllers for your next project, it's essential to focus on key specifications that ensure optimal performance. Top controllers on the market today offer features such as high-speed processing, precise motion control, and robust communication protocols. Look for controllers that support advanced features like adaptive speed control, which can enhance performance in dynamic applications such as electric vehicles. Recent industry reports indicate that implementing fuzzy logic in closed-loop systems can significantly improve the efficiency of brushless DC motors, with performance gains of up to 30% in some cases.

Tips: When comparing different models, pay close attention to operational bandwidth and response time. Controllers with faster response times can better accommodate rapid changes in operational parameters, leading to smoother performance. Additionally, evaluate the compatibility with existing systems; a well-integrated controller can save time during deployment and reduce overall project costs.

Furthermore, consider the scalability of the controller. As project requirements evolve, having a controller that can adapt to different motor types or configurations opens up new possibilities for innovation. Statistics show that systems designed for scalability typically reduce long-term maintenance costs by 20-25%, ensuring a better return on investment.

When selecting a linear motor controller for your next project, energy efficiency is a crucial factor that can significantly impact performance and operational costs. In a comparative analysis of leading linear motor controllers, metrics such as power consumption, thermal management, and operational speed must be evaluated. High-energy efficiency not only reduces electricity bills but also enhances the lifespan of both the motor and controller, making it a wise investment for long-term projects.

Tips: Always check the controller’s efficiency ratings provided by the manufacturer, as these can vary widely among models. Consider the application's specific requirements—certain controllers may excel in high-load conditions while others might be more efficient at lower speeds. Additionally, implementing a good cooling strategy can further enhance the performance and energy savings of your system.

Furthermore, emerging technologies and advanced algorithms in linear motor controllers could offer innovative solutions to energy efficiency. Features like regenerative braking and adaptive control strategies help to minimize energy loss. By understanding these capabilities, you can choose a controller that not only meets your project's technical specifications but also aligns with your energy sustainability goals.

This chart displays the energy efficiency metrics of the top 10 linear motor controllers considered for upcoming projects. The data is based on various performance tests that measure efficiency.

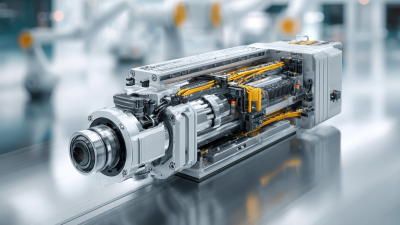

The automation industry is experiencing a significant transformation with the rise of smart linear motor controllers. These advanced devices are not only enhancing precision in motion control but are also integrating sophisticated algorithms and communication capabilities that allow for real-time adjustments and diagnostics. This shift is largely driven by the increasing demand for efficiency and accuracy in various applications, ranging from robotics to conveyor systems. As industries strive for greater productivity, smart linear motor controllers are becoming essential components, providing improved performance compared to traditional controllers.

Moreover, the implementation of IoT technologies is propelling the evolution of linear motor controllers. These smart systems can connect to cloud platforms, enabling remote monitoring and data analysis, which in turn facilitates predictive maintenance. This trend enhances operational reliability and reduces downtime, making it a valuable investment for manufacturers. As automation applications expand, the importance of integrating smart technologies into linear motor controllers will become even more pronounced, positioning these devices at the forefront of innovation in the automation sector.

Investing in high-performance linear motor controllers can significantly enhance the success of engineering projects, particularly in sectors such as automation, robotics, and manufacturing. A recent report by ResearchAndMarkets estimates that the linear motor market will reach USD 6.5 billion by 2025, driven by the increasing demand for precision and speed in motion control applications. As projects scale in complexity, the need for reliable and efficient motion control solutions becomes crucial, underlining the value of investing in top-tier controllers.

Moreover, a cost-benefit analysis reveals that while the initial investment in high-performance linear motor controllers may be higher compared to standard options, the long-term savings often justify the price. According to a study by Mordor Intelligence, businesses that adopted advanced linear motor technologies reported a 20-30% reduction in maintenance costs and improved energy efficiency by over 15%. These controllers not only provide enhanced performance but also contribute to lower operational costs and increased productivity, making them a strategic asset for project success.

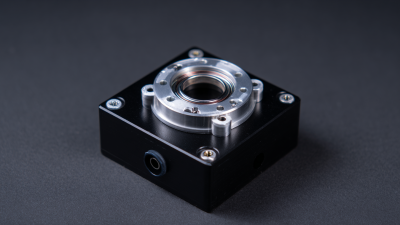

As technology continues to advance, the importance of compatibility with next-generation linear motor technologies cannot be overstated. When selecting linear motor controllers for your projects, it's crucial to consider how they will integrate with future innovations. These advancements can include improvements in efficiency, precision, and even integration with smart systems. A controller that is future-proof not only extends the life of your project but also aligns with the evolutionary nature of robotic and automation systems.

Compatibility with next-gen technologies typically involves an adaptable architecture that can accommodate emerging protocols and communication standards. Controllers designed with modularity in mind allow for upgrades without requiring a complete system overhaul. This foresight in design ensures that your investment remains relevant as industry standards evolve, enabling seamless integration with newer linear motors and sophisticated feedback mechanisms. By prioritizing compatibility, engineers can reduce long-term costs and enhance the overall performance and adaptability of their systems in rapidly changing technological landscapes.

| Controller Model | Max Current (A) | Voltage Range (V) | Control Type | Communication Protocols | Compatibility |

|---|---|---|---|---|---|

| Model A | 30 | 24 - 48 | PID | Ethernet, RS-485 | Next-Gen Capable |

| Model B | 25 | 20 - 60 | FB Control | CANopen, Modbus | Future-Ready |

| Model C | 40 | 12 - 48 | Open Loop | USB, Bluetooth | Compatible with new tech |

| Model D | 20 | 10 - 36 | Closed Loop | Serial, I2C | Upgrade Friendly |

| Model E | 35 | 24 - 72 | Torque Control | EtherCAT, Ethernet | Next-Gen Ready |

| Model F | 50 | 36 - 100 | Velocity Control | RS-232, CAN | Adaptable |

| Model G | 30 | 15 - 50 | Position Control | Bluetooth, ZigBee | Scalable |

| Model H | 45 | 48 - 120 | Hybrid Control | Ethernet, RS-485 | Future-Proof |

| Model I | 60 | 24 - 96 | Advanced Control | Modbus, CANopen | Very Compatible |

| Model J | 80 | 50 - 180 | Feedback Control | EtherCAT, Serial | Highly Flexible |

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.