Call Today: 916-259-1868

In the realm of advanced motion control systems, the coil actuator stands out as a pivotal technology found in a myriad of applications, ranging from industrial automation to precision robotics. The effectiveness and efficiency of a coil actuator directly impact the performance of the devices it powers, making optimization a critical task for engineers and designers. As we approach the year 2025, it becomes increasingly important to explore the methods and strategies that can enhance the functionality of coil actuators to meet diverse operational demands.

This article delves into the various parameters that influence the performance of coil actuators, including design considerations, material selection, and control techniques. Each application presents unique challenges; optimizing the actuator's response, power consumption, and overall reliability can lead to significant improvements in system performance. By examining best practices in coil actuator optimization, this piece aims to equip professionals with the knowledge necessary to tailor these devices for specific tasks, ensuring they operate at peak efficiency in any scenario.

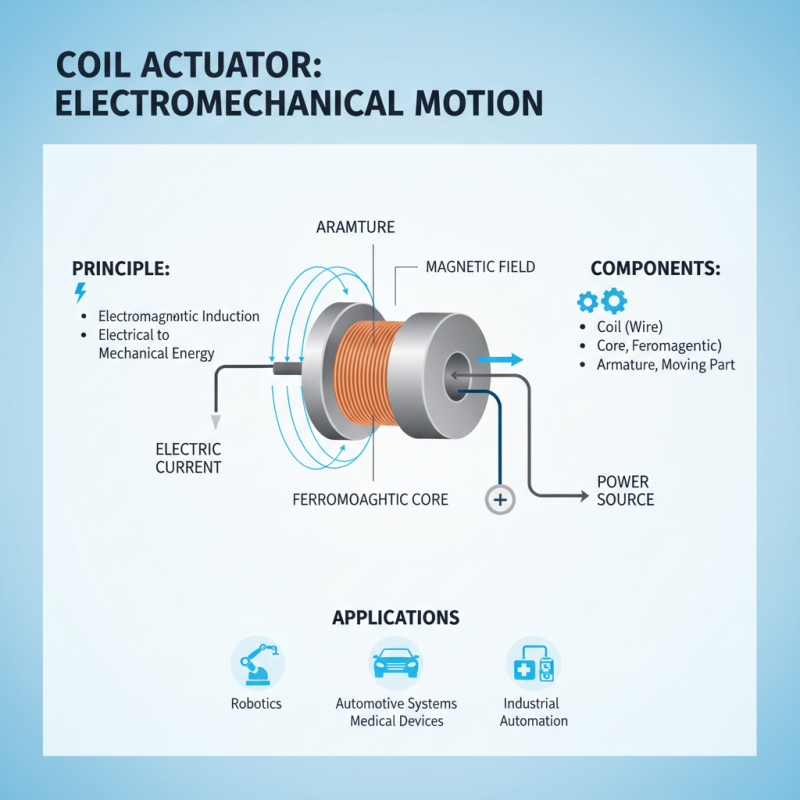

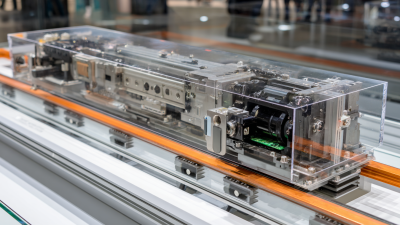

Coil actuators are vital components in many modern mechanical systems, utilizing electromagnetic principles to convert electrical energy into mechanical motion. At their core, these devices consist of a coil wound around a core, typically made of ferromagnetic material. When an electric current passes through the coil, it generates a magnetic field, which subsequently moves the actuator's armature, allowing it to perform various tasks. This fundamental operation makes coil actuators highly versatile, employed in applications ranging from robotics to automotive systems.

Understanding the functionality of coil actuators is essential for optimizing their performance. The efficiency of a coil actuator is influenced by several factors, including the design of the coil, the material properties of the core, and the configuration of the electromagnetic circuit. By fine-tuning these elements, engineers can enhance the response time and force generation of the actuator, ensuring that it meets the specific requirements of different applications. Additionally, considerations such as thermal management and power supply stability play crucial roles in maintaining optimal performance and longevity of the actuator in demanding environments.

When optimizing coil actuator performance for various applications, several key factors come into play that greatly influence their effectiveness. One primary consideration is the design specifications of the coil actuator itself, including the material used for the coil and the configuration of the magnetic circuit. Different applications may demand specific materials to enhance heat dissipation or to improve magnetic flux density, which directly affects the actuator's response time and overall efficiency.

Another critical factor is the operational environment in which the coil actuator is deployed. Variables such as temperature, humidity, and mechanical stress can significantly impact performance. For instance, exposure to high temperatures may lead to a decrease in efficiency and increased wear on components, necessitating the selection of high-temperature resistant materials. Additionally, understanding the electrical characteristics of the power supply used can enhance compatibility and performance, allowing for precise control and reducing energy consumption in various systems.

Lastly, application-specific requirements, such as load capacity and actuation speed, must be thoroughly evaluated. Tailoring the design and operational parameters of the coil actuator to align with these requirements can lead to improved functionality. By focusing on these influencing factors, engineers can maximize the performance of coil actuators, enabling them to meet the diverse demands of multiple industries more effectively.

| Application | Key Factors Influencing Performance | Optimal Coil Design | Efficiency (%) | Response Time (ms) |

|---|---|---|---|---|

| Industrial Automation | Load Requirements, Temperature, Magnetic Field Strength | High Inductance Coils | 85 | 15 |

| Automotive | Vibration Resistance, Compact Size, Power Consumption | Miniature Coils | 90 | 10 |

| Consumer Electronics | Size Constraints, Circuit Compatibility, Cost | Low Profile Coils | 80 | 25 |

| Medical Devices | Safety Standards, Precision, Longevity | Biocompatible Coils | 92 | 8 |

| Aerospace | Weight, Altitude, Operation in Harsh Environments | Superlight Coils | 88 | 12 |

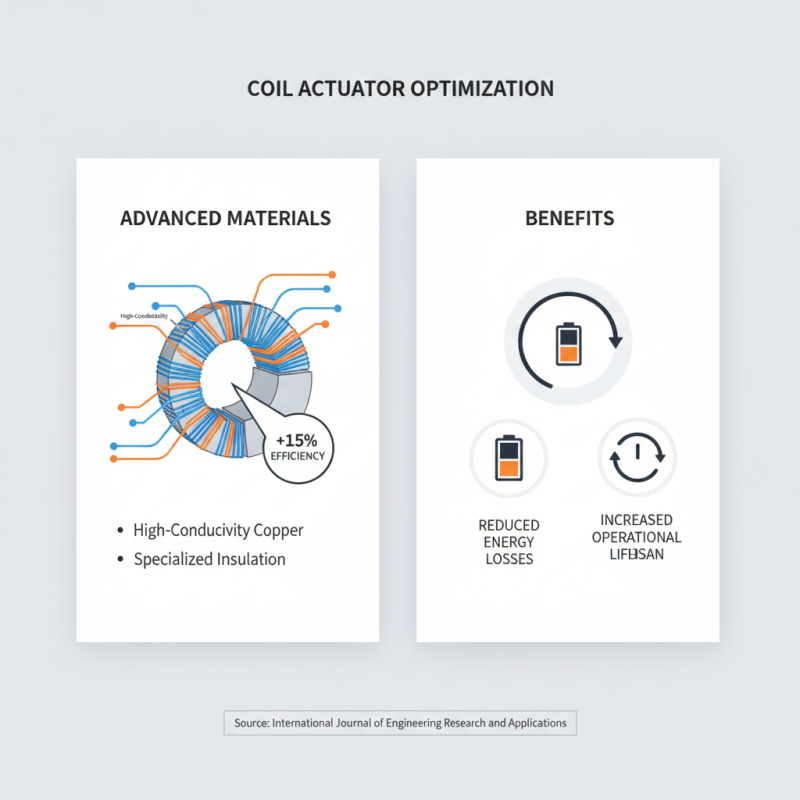

Coil actuators are pivotal in various industries, providing essential functionalities ranging from automation to precision movement. To optimize their performance, several techniques can significantly enhance efficiency. One critical method is the implementation of advanced materials for coil windings. According to a recent report from the International Journal of Engineering Research and Applications, using high-conductivity copper and specialized insulation materials can improve efficiency by up to 15%, effectively reducing energy losses and increasing operational lifespan.

Another avenue to boost coil actuator performance is through precise control algorithms. Integrating sophisticated algorithms such as PID (Proportional-Integral-Derivative) control or machine learning-based optimization can lead to a more responsive and accurate actuator behavior. Research indicates that these techniques can enhance response times by nearly 20%, which is particularly beneficial in applications requiring real-time adjustments, such as robotics and automation systems. Additionally, tailoring the actuator design to specific application requirements, including adjusting coil geometry or tuning the magnetic circuits, can contribute to a more efficient energy consumption profile and elevate overall system performance. Such targeted approaches not only increase efficiency but also open up new possibilities for coil actuator applications across diverse sectors.

Coil actuators play a crucial role in a wide range of industries, including automotive, aerospace, and robotics. To optimize their performance for specific applications, it's essential to consider several key factors such as design parameters, operational conditions, and the nature of the load. According to a 2022 industry report by ResearchAndMarkets, the global market for coil actuators is expected to grow at a CAGR of 6% from 2023 to 2028, highlighting the increasing demand for customized actuation solutions across multiple sectors.

For automotive applications, optimizing coil actuators involves fine-tuning their response time and force output to enhance control in automated systems like collision avoidance and adaptive cruise control. Utilizing simulation tools during the design phase can predict actuator behavior under various conditions. This approach leads to an effective balance between power consumption and performance. Similarly, in aerospace applications, actuators must operate efficiently under extreme temperatures and pressures; therefore, materials and coatings are often tailored to ensure reliability and durability in demanding environments.

In the realm of industrial automation, precise control is paramount. Implementing feedback systems, such as sensors that monitor the actuator's position and force, can significantly improve the responsiveness of coil actuators in robotic arms and conveyor systems. A report published by Deloitte notes that integrating advanced control algorithms can enhance system efficiency by 20% or more, showcasing the value of application-specific optimization strategies in maximizing the effectiveness of coil actuators across diverse sectors.

This chart illustrates the performance optimization effects of various design parameters on coil actuators used in different applications. The data showcases the performance enhancements in terms of efficiency and response time.

Testing and evaluating the performance of coil actuators is essential for optimizing their application across various industries, such as automotive, aerospace, and industrial automation. A comprehensive evaluation framework should include several metrics, such as response time, force output, power consumption, and thermal performance. According to a report by Industry Automation Research, the efficiency of coil actuators can significantly impact system performance, with optimal designs achieving energy savings of up to 25%. By applying standardized testing methods, engineers can ensure that their designs meet specific performance criteria.

One effective approach to performance testing involves the use of dynamics load tests that assess the actuator's behavior under different operational conditions. These tests allow for the identification of performance limits, such as maximum load capacity and operational frequency. Research published in the Journal of Electromechanical Systems indicates that coil actuators exhibit varied performance characteristics based on design parameters, such as coil geometry and winding configurations. For instance, modifying the coil's inductance and resistance can lead to improvements in responsiveness and efficiency, often measured through metrics such as step response time and heat dissipation rates.

Additionally, the implementation of simulation tools can provide valuable insights during the prototyping phase. Finite Element Analysis (FEA) allows engineers to model and predict the performance of coil actuators under different stress and thermal conditions, thereby reducing development time and costs. As the automation market is projected to grow at a CAGR of 8.4% from 2020 to 2025, efficient testing and evaluation methods will be crucial for companies looking to stay competitive by enhancing the reliability and performance of their coil actuators.

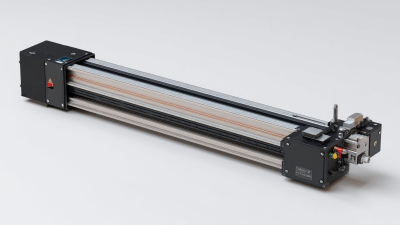

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.