Call Today: 916-259-1868

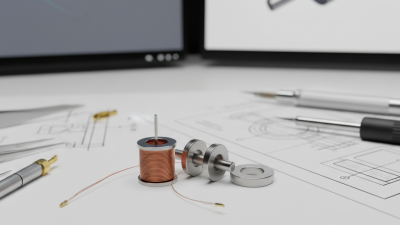

In precision applications, the choice of actuator is crucial. Miniature voice coil actuators stand out due to their compact design and high responsiveness. According to a recent industry report, the demand for these actuators is expected to grow by 15% annually. This growth is driven by sectors like robotics, medical devices, and aerospace.

These actuators offer precise control, allowing for finer adjustments in a limited space. Their simple construction results in lower manufacturing costs. Moreover, they deliver significant force within a small footprint. However, designers must consider specific limitations, such as thermal effects and non-linearities in performance.

The versatility of miniature voice coil actuators makes them appealing. Yet, they require careful integration to achieve optimal results. Understanding their specifications and potential trade-offs is essential for engineers. A well-informed choice can lead to innovative solutions in demanding applications.

Miniature voice coil actuators are gaining traction in precision engineering. They provide unique advantages that stand out. First, their compact size allows for integration into tight spaces. This is crucial in applications where every millimeter matters. Additionally, their quick response time enhances operational efficiency. This leads to improved responsiveness in dynamic systems.

Tips: When selecting a miniature voice coil actuator, consider the load requirements. Ensure that the actuator can handle the expected force without straining.

Another benefit is their simplicity in design. Fewer components generally mean lower failure rates. However, it’s essential to acknowledge the limitations. These actuators have maximum displacement constraints. Overextending their range may lead to performance issues.

Tips: Regularly check the actuator's operational range to prevent damage. Understand the specific dynamics of your application.

Lastly, the precision control offered by these actuators is remarkable. They maintain accuracy even in challenging environments. Still, thorough testing is necessary to fully understand their capabilities. It's easy to overlook nuances that could impact performance.

Miniature voice coil actuators are essential for precision applications. They are compact and efficient, ideal for tasks where space is limited. These actuators excel in delivering high performance in a small footprint. According to a report by MarketsandMarkets, the demand for miniature actuators is expected to grow significantly, driven by advancements in automation and robotics.

One key characteristic of these actuators is their rapid response time. They can operate within milliseconds, providing quick adjustments. This feature is critical in precise applications such as medical devices or optical systems. Additionally, they offer fine control over movement, with resolutions often reaching up to micrometers. Their non-contact design minimizes wear, enhancing durability and lifespan, making them highly reliable.

However, challenges exist. The low power capabilities of some miniature voice coil actuators may limit their applications. Also, heat generation needs careful management during operation to prevent performance issues. As industries push for greater precision, understanding these limitations is crucial for effective implementation. Balancing size, power, and efficiency remains a topic of ongoing research and development.

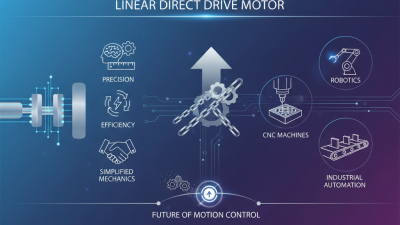

Miniature voice coil actuators are ideal for a variety of applications. They excel in environments where precision is crucial. For instance, in medical devices, these actuators control delicate movements. Think about surgical instruments that require exact positioning. This level of control can mean the difference between success and failure.

Moreover, in optical systems, precision is non-negotiable. Miniature voice coil actuators adjust lenses and mirrors with remarkable accuracy. These small devices can move in increments that are hard to perceive. This ability to fine-tune can enhance image quality significantly. Yet, designing these systems is challenging. Engineers must balance force, size, and speed. Finding the right actuator for specific needs requires careful thought.

Manufacturing automation also benefits from miniature voice coil actuators. They help robots execute tasks with speed and precision. In assembly lines, even minor movements impact overall efficiency. Using these actuators can optimize the precision needed in repetitive tasks. Handling them properly during integration is critical. Any oversight can lead to inconsistencies. This underscores the importance of diligence in design and application.

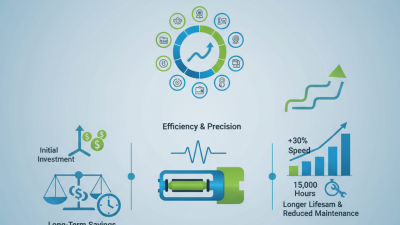

Miniature voice coil actuators (VCAs) are gaining traction in precision applications. They offer distinct advantages over traditional actuation technologies, like solenoids or pneumatic systems. For example, VCAs can provide response times as fast as 1 millisecond, whereas traditional systems often lag at around 10 milliseconds. This speed can make a significant difference in applications requiring quick adjustments, such as optical alignment in lasers.

Moreover, VCAs excel in control accuracy. They can achieve positioning resolutions in the micrometer range. Traditional actuators, on the other hand, may struggle with precision, particularly under load. According to recent industry reports, VCAs can attain positioning accuracies of up to 0.1% of the full stroke, compared to at least 1% in traditional systems. This translates to better performance in high-stakes environments, like medical devices or aerospace applications.

However, choosing VCAs isn't just a straightforward decision. Their compact size can pose challenges for cooling and heat dissipation. In addition, integration with existing systems may require more effort. These factors warrant careful consideration during the selection process. Despite these hurdles, the advantages of VCAs in performance and precision cannot be ignored. They represent a viable option for applications demanding high standards.

When selecting a miniature voice coil actuator, several factors matter. First, consider the size and weight of your application. Compact spaces require light actuators that fit seamlessly. Heavy or bulky options may lead to installation challenges. Aim for a model that strikes the right balance between power and size.

Next, examine the force-output requirements. Different applications demand varying levels of force. Understand the load conditions your actuator will face. Decide if you need precision movement or high speed. Each choice impacts application performance. Note that finding the perfect fit often involves trade-offs. You may sacrifice some speed for accuracy or vice versa.

Lastly, take into account the power supply and control options. How easily can the actuator connect to your system? Compatibility with your existing setup simplifies integration. Ensure the actuator’s characteristics align with power availability. In the end, the selection process can feel overwhelming. You might not find the ideal solution right away, requiring further adjustments and re-evaluations.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.