Call Today: 916-259-1868

In the rapidly evolving field of automation and motion control, "magnetic linear drive" systems have emerged as a game-changing technology, offering unparalleled efficiency and performance for various applications. According to Dr. Emily Chen, a leading expert in motion engineering, "The advent of magnetic linear drives represents a significant leap forward; they not only simplify design but also enhance precision while reducing maintenance costs." This insight underscores the growing importance of understanding and selecting the right magnetic linear drive systems for optimal results.

As industries across the globe strive for greater automation and productivity, the demand for reliable and efficient drive systems continues to rise. Magnetic linear drives utilize magnetic fields to achieve smooth and direct motion without the need for mechanical contact, reducing wear and tear while providing high-speed operation. The increasing adoption of these systems in manufacturing, robotics, and transport signifies their pivotal role in modern engineering.

This article delves into the top five magnetic linear drive systems available on the market today. By examining their features, performance metrics, and application suitability, we aim to equip decision-makers with the knowledge necessary to make informed choices in their pursuit of enhanced efficiency and performance. Whether you are in the automotive sector, robotics, or material handling, understanding these innovative systems is key to staying ahead in a competitive landscape.

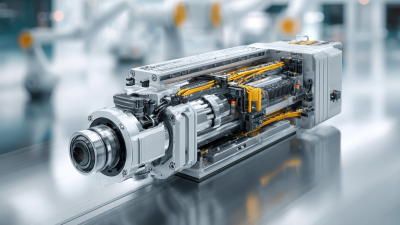

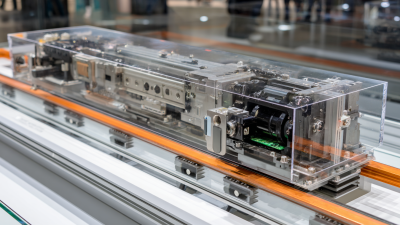

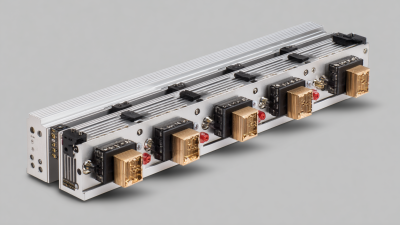

Magnetic linear drive systems represent a significant advancement in motion control technology, utilizing magnetic fields to create linear motion without the need for traditional mechanical components. These systems operate on the principle of electromagnetic forces, providing smooth, efficient, and precise movement. Their design eliminates friction and wear commonly associated with mechanical systems, resulting in lower maintenance requirements and longer lifespans. This efficiency is particularly beneficial in applications requiring high-speed operation and accurate positioning, such as automation, robotics, and material handling.

The versatility of magnetic linear drives enhances their appeal across various industries. In manufacturing, they enable rapid transport of fragile materials, ensuring they remain undisturbed during transit. In healthcare, precision drive systems are utilized in MRI machines and robotic surgical tools, where accuracy and reliability are paramount. Furthermore, these systems play a crucial role in advanced manufacturing technologies, including 3D printing and CNC machining, where exactness can significantly impact product quality. As industries continue to seek innovative solutions for efficiency and performance, magnetic linear drive systems stand out as a leading choice for modern applications.

When evaluating the efficiency of magnetic linear drive systems, several key factors come into play. One of the most significant aspects is the design of the magnetic circuit. An optimized design ensures that magnetic flux is efficiently utilized, minimizing losses due to leakage or saturation. High-quality materials for magnets and coils also play a crucial role, as they can greatly impact the overall performance, leading to smoother operation and reduced energy consumption.

Another critical factor influencing the efficiency of magnetic linear drives is the control system employed. Advanced control algorithms can enhance the precision and responsiveness of the drive, resulting in better performance characteristics. Additionally, the integration of sensors for feedback allows for real-time adjustments to optimize the drive's operation under varying load conditions. This adaptability makes it possible to achieve higher overall efficiency, even in dynamic environments where performance can fluctuate.

When selecting the best magnetic linear drive systems, it's essential to consider their features and specifications to maximize efficiency and performance. These systems typically include elements like high-speed capabilities, precise positioning accuracy, and low maintenance requirements. A top-performing magnetic linear drive should ideally feature a robust design that minimizes friction and wear, thereby prolonging its lifespan and ensuring consistent operation.

One of the standout features to look for is the integrated feedback mechanism, which enhances the control and precision of the system. Additionally, many contemporary systems are designed to be compact and lightweight, facilitating easier integration into existing machinery without compromising on strength or durability. High force output relative to size is another significant specification that can drastically improve system productivity.

Tips: When evaluating magnetic linear drive systems, always consider the specific application you have in mind. Different systems may excel in particular niches—be sure to analyze intricate details such as load capacity and speed requirements. Another important factor is the thermal management capability; effective cooling systems are vital for maintaining optimal performance during extended operations.

| Model | Max Speed (m/s) | Payload Capacity (kg) | Stroke Length (mm) | Power Consumption (W) | Efficiency (%) |

|---|---|---|---|---|---|

| Model A | 3.5 | 50 | 1000 | 150 | 90 |

| Model B | 4.0 | 60 | 1200 | 180 | 92 |

| Model C | 5.5 | 70 | 1500 | 200 | 95 |

| Model D | 6.0 | 80 | 1400 | 250 | 93 |

| Model E | 7.0 | 90 | 1600 | 275 | 96 |

The performance of magnetic linear drive systems can be assessed through various metrics that indicate their efficiency and suitability for diverse applications. Key performance indicators typically include speed, acceleration, force output, and energy consumption. By analyzing these metrics, one can discern how different systems cater to unique operational needs. For instance, systems designed for high-speed applications may prioritize rapid acceleration and deceleration capabilities, whereas those intended for heavy loads may focus more on force output and stability at lower speeds.

In a comparative analysis, it becomes evident that not all magnetic linear drive systems are created equal. Some systems excel in energy efficiency, utilizing advanced technologies that minimize power consumption while maintaining performance levels. Others may demonstrate significant advantages in responsiveness and precision, essential for applications in automation and robotics. By taking a deeper look at these performance metrics, engineers and operators can make informed decisions, selecting the most appropriate magnetic linear drive system tailored to specific operational requirements.

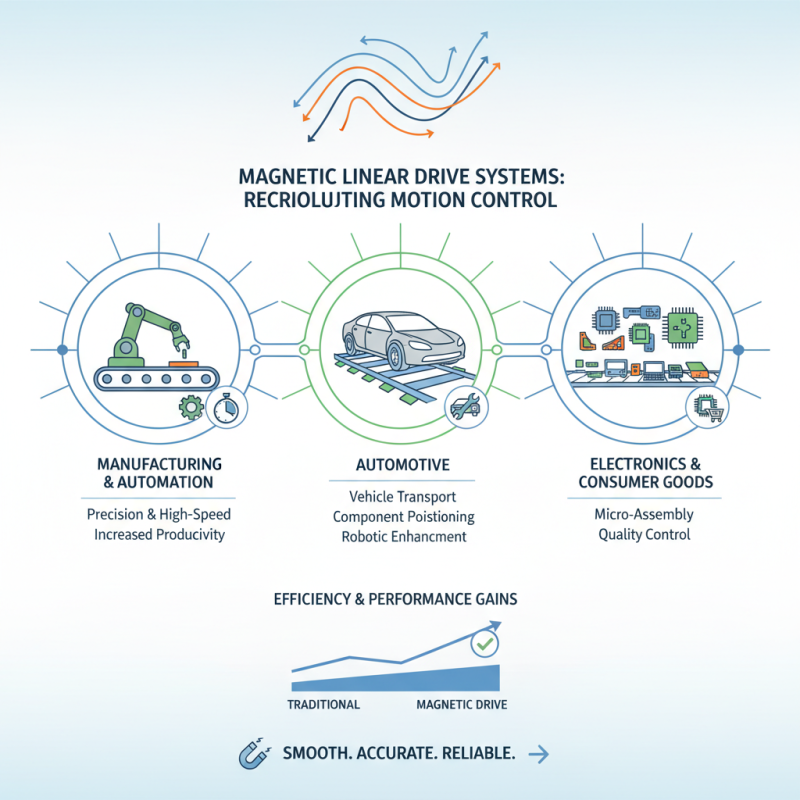

Magnetic linear drive systems are revolutionizing various industries by providing efficient and high-performance solutions for motion control. One of the primary use cases is in manufacturing, where these systems are employed in automated assembly lines. Their precision and high-speed capabilities significantly increase productivity by ensuring smooth and accurate movement of components. Industries such as automotive, electronics, and consumer goods heavily rely on magnetic drives for tasks like positioning, transporting materials, and enhancing robotic automation.

Another significant application of magnetic linear drives is in the transportation sector, particularly in magnetic levitation (maglev) trains. These systems enable high-speed travel with minimal friction, resulting in lower energy consumption and reduced wear on components. Additionally, magnetic drives are finding uses in medical equipment, such as MRI machines, where precision and cleanliness are crucial. The healthcare sector is increasingly adopting these systems for patient positioning and in surgical robots, demonstrating their versatility and impact across multiple fields.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.