Call Today: 916-259-1868

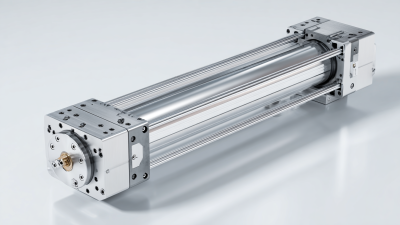

In the rapidly evolving landscape of manufacturing, the integration of advanced technologies is pivotal for enhancing automation and precision. Among these innovations, the linear voice coil motor (LVCM) stands out for its ability to provide high-performance motion control, thereby significantly improving production efficiency. According to a report by MarketsandMarkets, the global linear motor market is projected to reach $3.24 billion by 2026, with LVCMs playing a critical role in sectors such as automotive, electronics, and robotics. The unique characteristics of LVCMs, including high acceleration, precise positioning, and low maintenance needs, enable manufacturers to optimize processes and achieve greater productivity. As industries continue to adopt automation strategies, understanding the advantages of linear voice coil motors will be essential for staying competitive in the market.

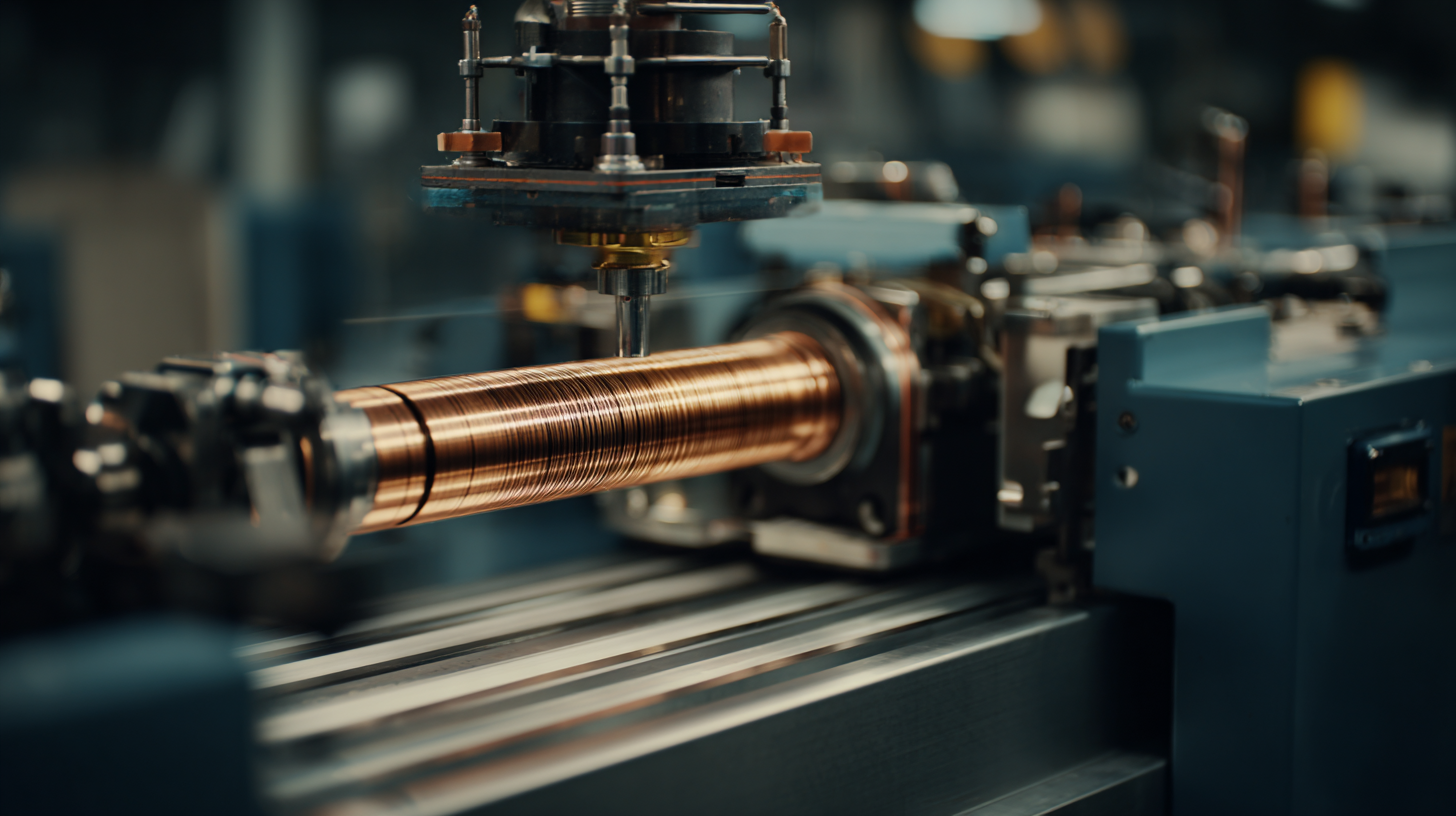

Linear voice coil motors (VCMs) are pivotal components in modern manufacturing automation, offering precise control in various applications. These motors operate on the principle of

electromagnetic induction, enabling fast and accurate positioning, which is crucial for tasks that require meticulous movement.

Their mechanism involves a coil suspended in a magnetic field, allowing for linear motion with minimal friction. This design leads to high responsiveness, translating into efficient operation in manufacturing processes, especially when precision is paramount.

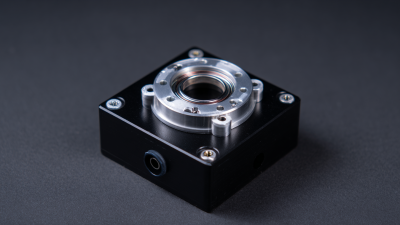

Recent advancements highlight the versatility of VCMs across different sectors. For instance, their application in miniature camera modules showcases the integration of hollow linear ultrasonic motors for focusing mechanisms.

This innovation not only enhances the camera's precision but also caters to the increasing demand for compact design in technology. Similarly, the anticipated growth

in the voice coil motor market underscores the rising importance of these devices in various sectors, including automation and medical technologies.

With projections indicating substantial market increases, it's evident that VCMs will play a critical role in shaping the future landscape of manufacturing automation.

Linear voice coil motors (VCMs) are revolutionizing automation in manufacturing by offering unmatched precision and efficiency. Their compact design and high force-to-size ratio make them ideal for demanding applications, such as in surgical robots and precision assembly lines. As the industry anticipates continued growth, the VCM market is projected to increase from approximately $3.53 billion in 2023 to around $6.91 billion by 2033, demonstrating a robust CAGR of 6.1%. This significant growth emphasizes the increasing reliance on linear voice coil motors to enhance the capabilities of automated systems.

Implementing linear voice coil motors presents several advantages for manufacturing processes. These motors provide rapid acceleration and precise positioning, which are crucial for maintaining quality standards in high-speed production environments. For instance, the latest advancements in VCM technology have led to the development of units that are not only smaller but capable of producing high force with low energy consumption. This is an essential factor for manufacturers aiming to increase operational efficiency while minimizing costs.

Tips: When considering the integration of linear voice coil motors, it's essential to evaluate the specific requirements of your applications. Additionally, monitor emerging technologies and market trends to leverage innovations that could enhance your automation strategies further. Always consult with experts to ensure optimal performance and alignment with industry standards.

| Dimension | Description | Advantages |

|---|---|---|

| Precision | Ability to achieve high levels of accuracy in motion control. | Enhanced product quality and reduced waste. |

| Response Time | Fast actuation and movement adjustments. | Increased production speed and efficiency. |

| Load Capacity | Ability to handle varying loads with stability. | Flexibility in manufacturing processes. |

| Integration | Compatibility with existing systems and technologies. | Ease of implementation and minimized downtime. |

| Maintenance | Low maintenance requirements. | Cost savings over time. |

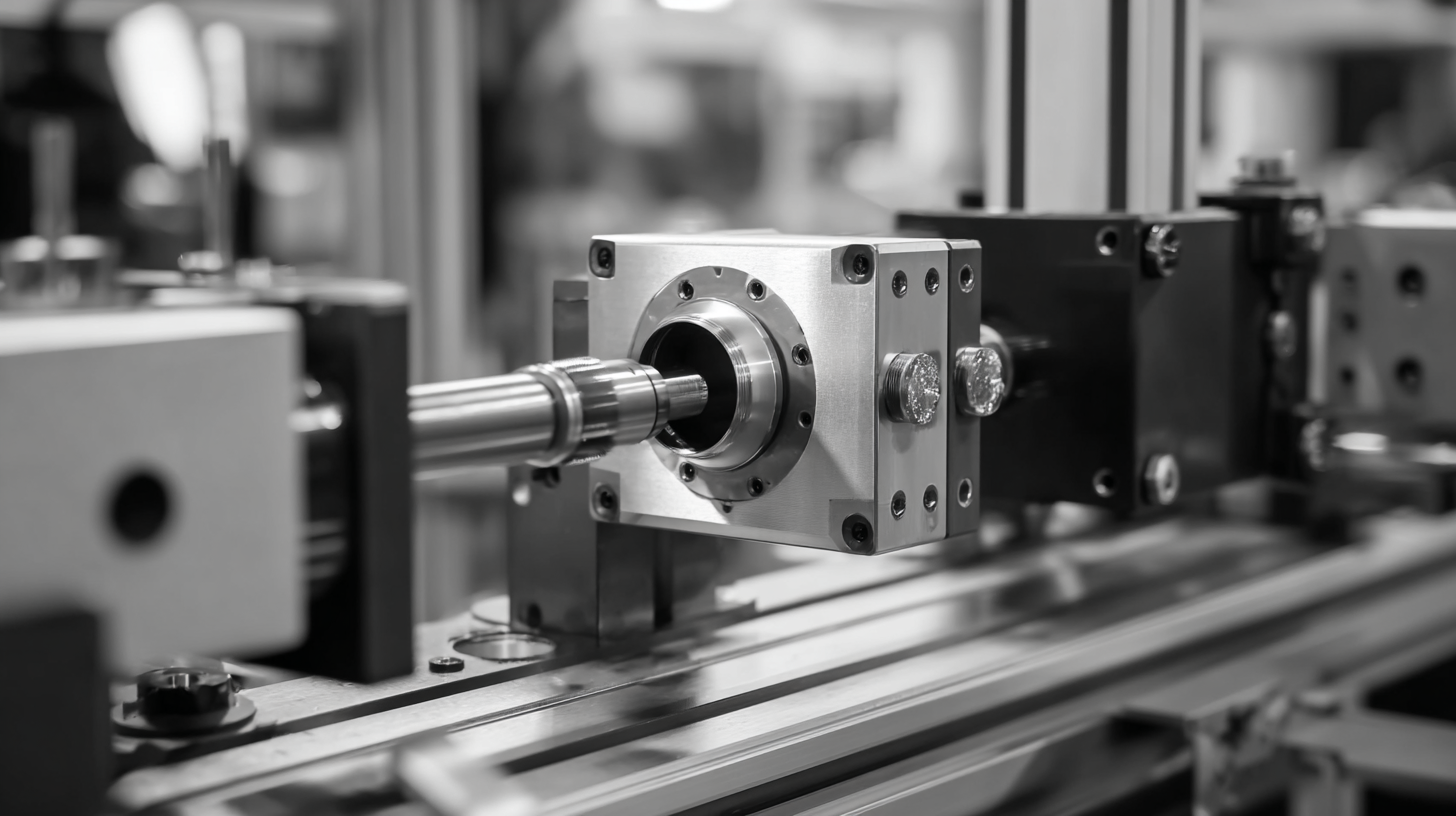

Linear Voice Coil Motors (VCMs) are revolutionizing automation in manufacturing processes, especially in applications requiring

high precision and compact design. These motors are increasingly utilized in industries such as electronics, medical devices, and robotics, where exact movements are critical. With capabilities to deliver motion increments as small as one nanometer, VCMs enable

advanced functionalities such as optical focusing, laser machining, and precise positioning in assembly lines. Their

brushless design and zero cogging characteristics make them ideal for environments demanding both speed and accuracy.

Linear Voice Coil Motors (VCMs) are revolutionizing automation in manufacturing processes, especially in applications requiring

high precision and compact design. These motors are increasingly utilized in industries such as electronics, medical devices, and robotics, where exact movements are critical. With capabilities to deliver motion increments as small as one nanometer, VCMs enable

advanced functionalities such as optical focusing, laser machining, and precise positioning in assembly lines. Their

brushless design and zero cogging characteristics make them ideal for environments demanding both speed and accuracy.

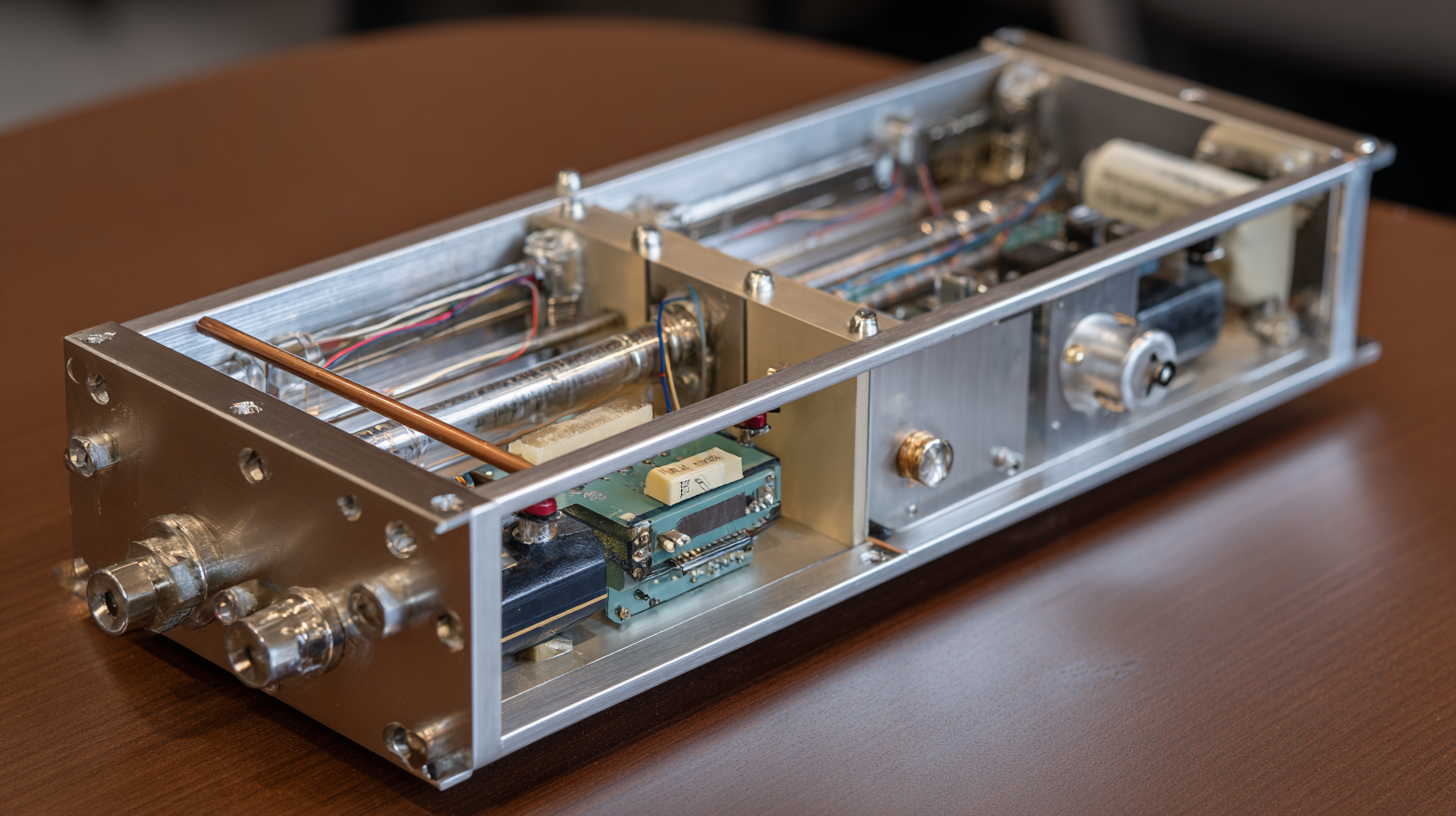

One notable application of linear voice coil motors is in nanopositioning systems, which require high-resolution actuation for tasks such as wafer handling and dynamic vibration control. The miniature versions of these motors, with compact strokes and high efficiency, meet the industry's demand for smaller components without compromising performance. As the market for humanoid robots and other automated solutions expands, the role of linear voice coil motors will become increasingly significant, ensuring that manufacturing processes remain at the cutting edge of precision engineering.

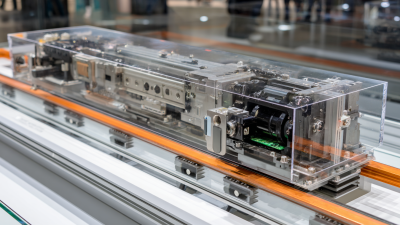

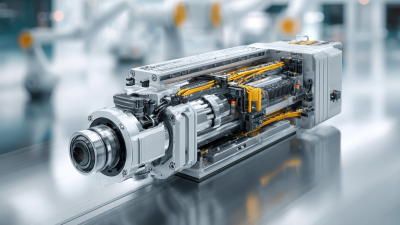

Integrating linear voice coil motors into manufacturing processes can significantly enhance automation efficiency. These motors provide precise control and rapid response, making them ideal for tasks that require high accuracy and reliability. According to a report by e-works Research, top manufacturers are increasingly adopting intelligent production lines equipped with automation solutions that leverage such advanced technologies, which can result in a 20-30% increase in productivity.

Integrating linear voice coil motors into manufacturing processes can significantly enhance automation efficiency. These motors provide precise control and rapid response, making them ideal for tasks that require high accuracy and reliability. According to a report by e-works Research, top manufacturers are increasingly adopting intelligent production lines equipped with automation solutions that leverage such advanced technologies, which can result in a 20-30% increase in productivity.

Tip: When integrating voice coil motors, ensure to conduct a thorough needs assessment to tailor the motor specifications to your unique production requirements. This will optimize performance and increase the lifespan of the machinery.

Recent advancements in smart manufacturing demonstrate the value of seamless automation. In an innovative setup, robotic arms work alongside intelligent logistics systems to streamline parts assembly and transportation. Implementing linear voice coil motors into these operations can drastically reduce cycle times, as they are capable of executing rapid linear movements that traditional motors may struggle to achieve.

Tip: It is crucial to prioritize the training of your workforce in handling new automation technologies effectively. This ensures that the team can maximize the potential of voice coil motors, leading to smoother transitions and operational efficiencies.

As we look towards the future of automation in manufacturing, the advancements in Linear Voice Coil Motor (VCM) technology are of critical importance. By 2025, humanoid robots are expected to enter mass production, significantly boosting industrial processes. This shift is not merely about manufacturing efficiency but also about enhancing precision and speed, which VCMs excel at. With their ability to deliver high-performance motion control, VCMs are reshaping automation landscapes, enabling the development of accelerated and more reliable production lines.

The VCM market shows promising growth forecasts, expected to rise from approximately 2.5 billion USD in 2024 to an impressive 4.1 billion USD by 2033, reflecting a compound annual growth rate (CAGR) of 6.1%. This surge underscores the increasing reliance on motion control technologies in various sectors, from robotics to aerospace. As manufacturers continue to recognize the advantages of VCMs in achieving precise movements and reducing cycle times, the integration of these motors into automation solutions will likely become more pronounced, paving the way for innovations and enhanced operational capabilities across industries.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.