Call Today: 916-259-1868

In today's fast-paced industrial landscape, the pursuit of efficiency and performance has never been more critical. Recent reports indicate that automation systems integrating linear motors can enhance overall operational effectiveness by over 30%, a substantial improvement that is hard to overlook (International Automation Association, 2023). Linear motors, known for their ability to provide direct drive solutions with minimal friction and wear, are changing the way industries operate. The rise of Industry 4.0 emphasizes the need for precision and speed, pushing manufacturers to adopt cutting-edge technologies. According to a study by the Robotics and Automation Journal, industries utilizing linear motors have reported reductions in cycle time and increased throughput, making them a central component in modern automation strategies. As companies strive to remain competitive in a global market, the implementation of linear motors stands out as a transformative approach to optimizing productivity and enhancing overall performance.

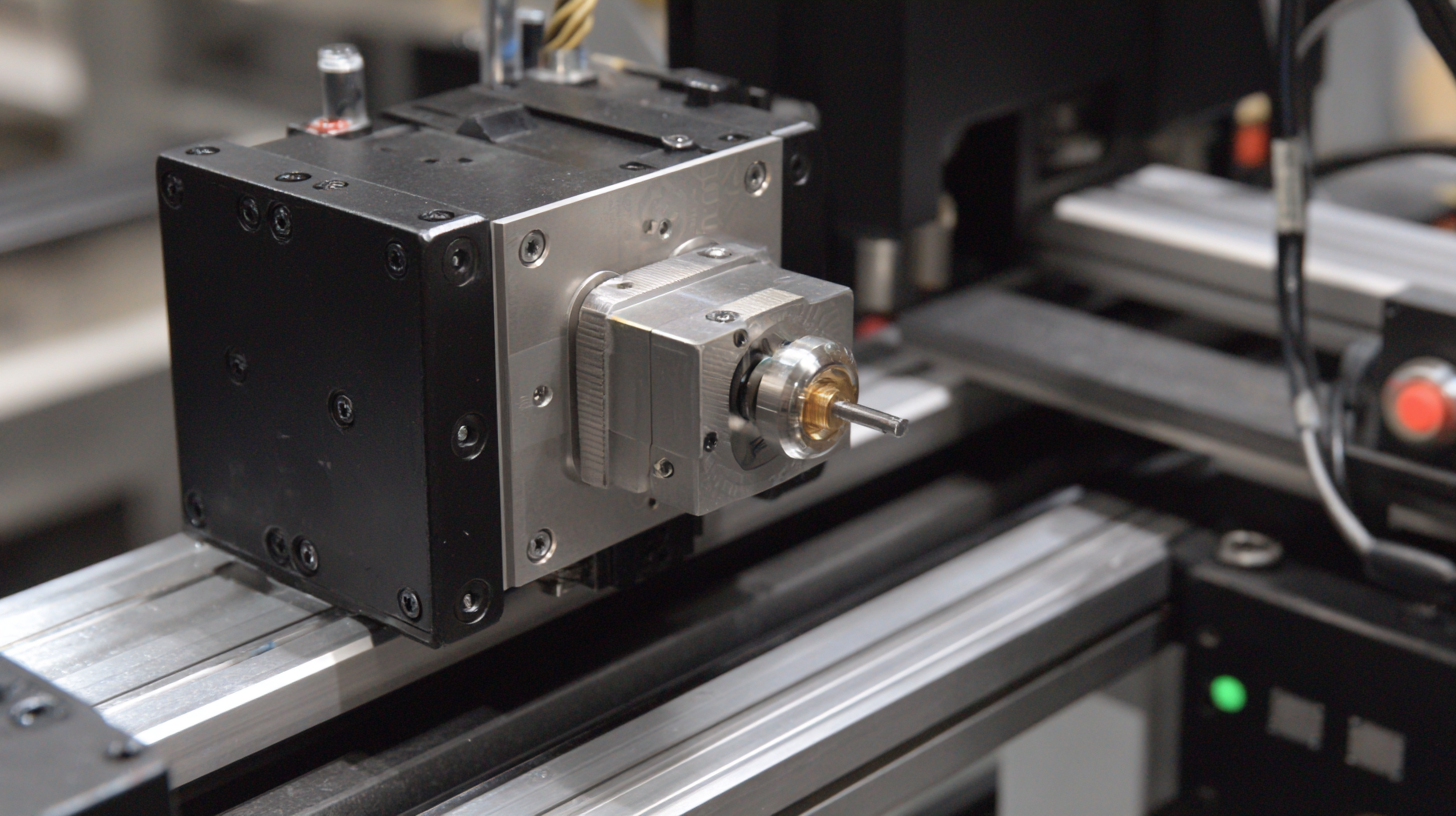

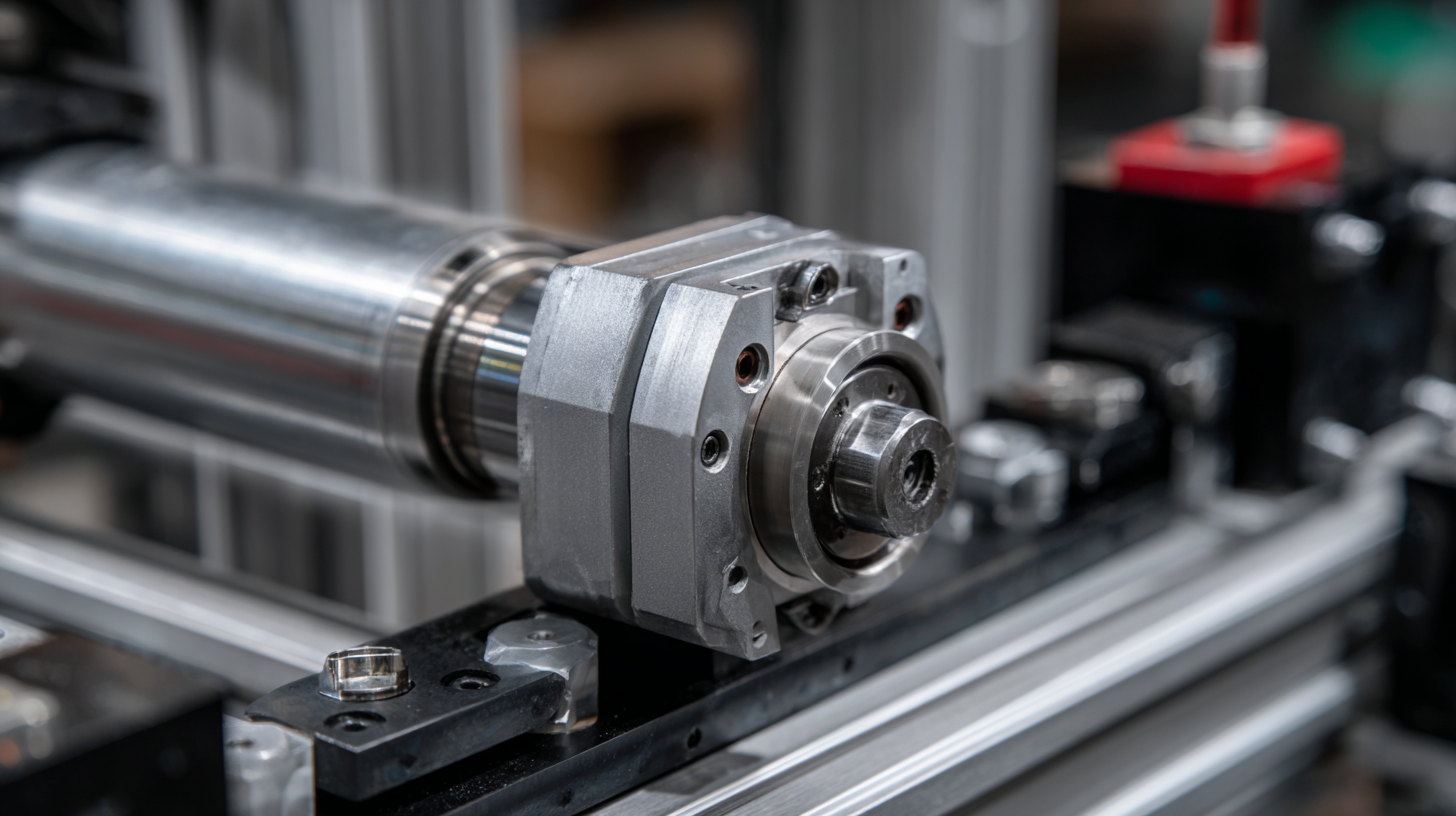

Linear motors are a transformative technology at the heart of modern automation systems, offering distinct advantages over traditional rotary motors. Operating on the principle of magnetic levitation, linear motors convert electrical energy directly into linear motion, allowing for greater precision and speed. This direct drive mechanism eliminates the need for mechanical components like gears and belts, which can introduce friction and limit performance. As a result, linear motors deliver smoother and more efficient motion, significantly enhancing the responsiveness of industrial applications.

In addition to improved speed and precision, linear motors provide remarkable scalability and flexibility in automation systems. Their design enables easy integration into various configurations, allowing for tailored solutions that meet specific operational needs. With their ability to maintain high performance over prolonged periods, linear motors can enhance productivity by reducing maintenance requirements and downtime. Furthermore, the higher acceleration and deceleration rates afforded by these motors lead to shorter cycle times, ultimately boosting overall system efficiency by more than 30%. This combination of factors makes linear motors an essential component in the advancement of automated processes across industries.

This chart illustrates the performance improvements when using linear motors compared to traditional motors in automation systems, showing a significant increase of over 30% in efficiency.

The integration of linear motors into automation systems has led to remarkable improvements in performance metrics, which are compelling for industries aiming to optimize productivity. According to a report by the International Society of Automation, systems that employ linear motors can achieve efficiency gains exceeding 30%, primarily due to their high acceleration rates and reduced mechanical complexity. This not only minimizes the energy consumption often associated with traditional rotary motors but also shortens cycle times in production environments.

Further analysis by the Manufacturing Technology Centre has revealed that linear motors significantly enhance operational flexibility, allowing automation systems to respond dynamically to varying production demands. Metrics show that these systems exhibit up to 50% faster response times, contributing to a more agile production line. Additionally, the elimination of mechanical wear found in traditional systems results in lower maintenance costs and increased uptime, translating into a more reliable operation over time. As industries continue to seek competitive advantages, the efficiency gains associated with linear motors make them an essential consideration for future automation strategies.

Integrating linear motors into existing automation systems offers a strategic pathway to enhance operational efficiency. A thorough assessment of the current system is essential to identify the areas where linear motors can provide the most significant impact. This involves analyzing the required speeds, precision, and load capacities of the tasks involved. Once the potential benefits are identified, organizations can begin selecting appropriate linear motor technologies that align with their operational needs.

Implementation strategies should also focus on seamless integration with legacy systems to minimize disruptions. Utilizing advanced control systems that support both traditional and linear motor technologies can facilitate a smooth transition. Training personnel on the new system is crucial to ensure that they can effectively operate and troubleshoot the updated machinery. Additionally, phased integration, where linear motors are deployed in stages, allows for continuous assessment and optimization, ultimately leading to a performance boost exceeding 30% in automation processes.

Linear motors are becoming increasingly vital in automation systems, offering significant performance enhancements of over 30%. However, deploying these advanced technologies presents several challenges that must be carefully navigated to maximize their benefits. Best practices for effectively incorporating linear motors into industrial applications include comprehensive training for personnel, modular designs for easier maintenance, and careful consideration of operational environments. Emphasizing precision and reliability can lead to improved automation processes, ultimately driving higher efficiency and reducing downtime.

Moreover, as industries strive towards sustainability, integrating linear motors can align with broader eco-friendly initiatives. By embracing these technologies, companies can not only enhance their operational capabilities but also contribute to sustainable development goals. This approach fosters a circular economy where resources are utilized more efficiently, aligning with the urgent need for innovative solutions in manufacturing and production sectors. The focus on precision in motion control allows for smarter resource management, ensuring that industries can meet both performance objectives and environmental responsibilities.

The landscape of automation systems is rapidly evolving, and innovations in linear motor technology are driving this transformation. Contemporary advancements are geared towards enhancing precision, speed, and reliability, enabling automation systems to operate with unprecedented efficiency. For instance, newer linear motor designs incorporate advanced materials and magnetic configurations that significantly reduce energy consumption while maximizing output. The implementation of smart sensors and control algorithms further enables real-time monitoring and adjustments, making systems more adaptive and responsive to varying operational demands.

Looking ahead, we can anticipate several emerging trends that will shape the future of linear motor technology and automation efficiency. The integration of artificial intelligence (AI) into linear motor systems is set to enhance predictive maintenance and optimize performance configurations. Furthermore, the development of compact and lightweight motor designs will facilitate easier integration into space-constrained environments, while advancements in sustainability will lead to greener production methods. These trends indicate a promising horizon where linear motors not only enhance the efficiencies of automation systems but also align with global sustainability goals, ultimately reshaping industries across the board.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.