Call Today: 916-259-1868

The rise of automation technology continues to transform industries, with cylindrical linear motors playing a pivotal role in this evolution. According to a report by MarketsandMarkets, the global linear motor market is projected to reach $6.98 billion by 2026, growing at a CAGR of 9.7% from 2021. This growth is primarily driven by the increasing demand for high-precision motion control solutions across various applications, including robotics and manufacturing. Cylindrical linear motors, known for their compact design and efficient operation, are emerging as a key component in optimizing production processes and enhancing operational efficiency. As companies seek to improve their automation capabilities, understanding the advantages and applications of cylindrical linear motors becomes crucial for staying competitive in a rapidly advancing technological landscape.

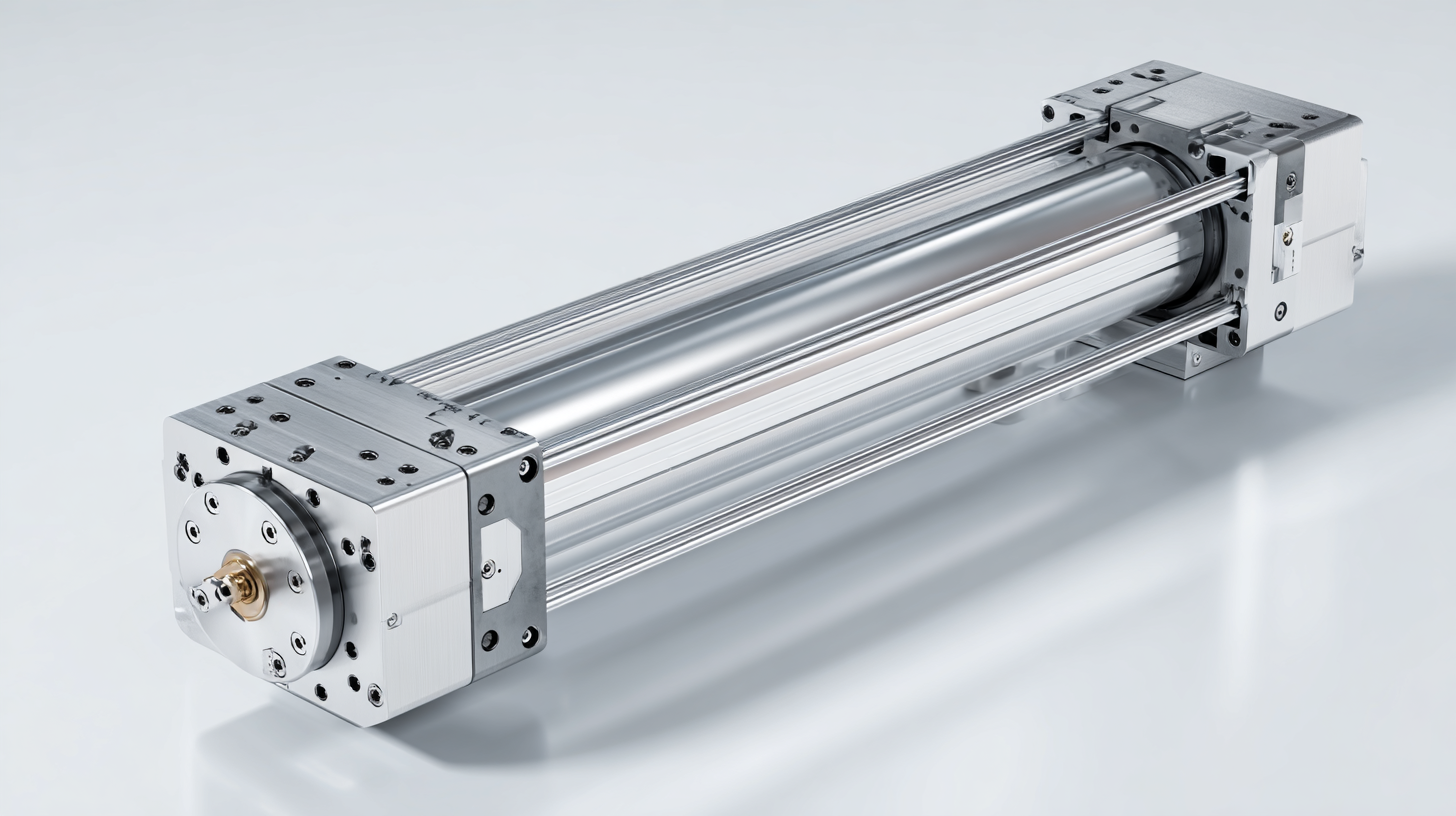

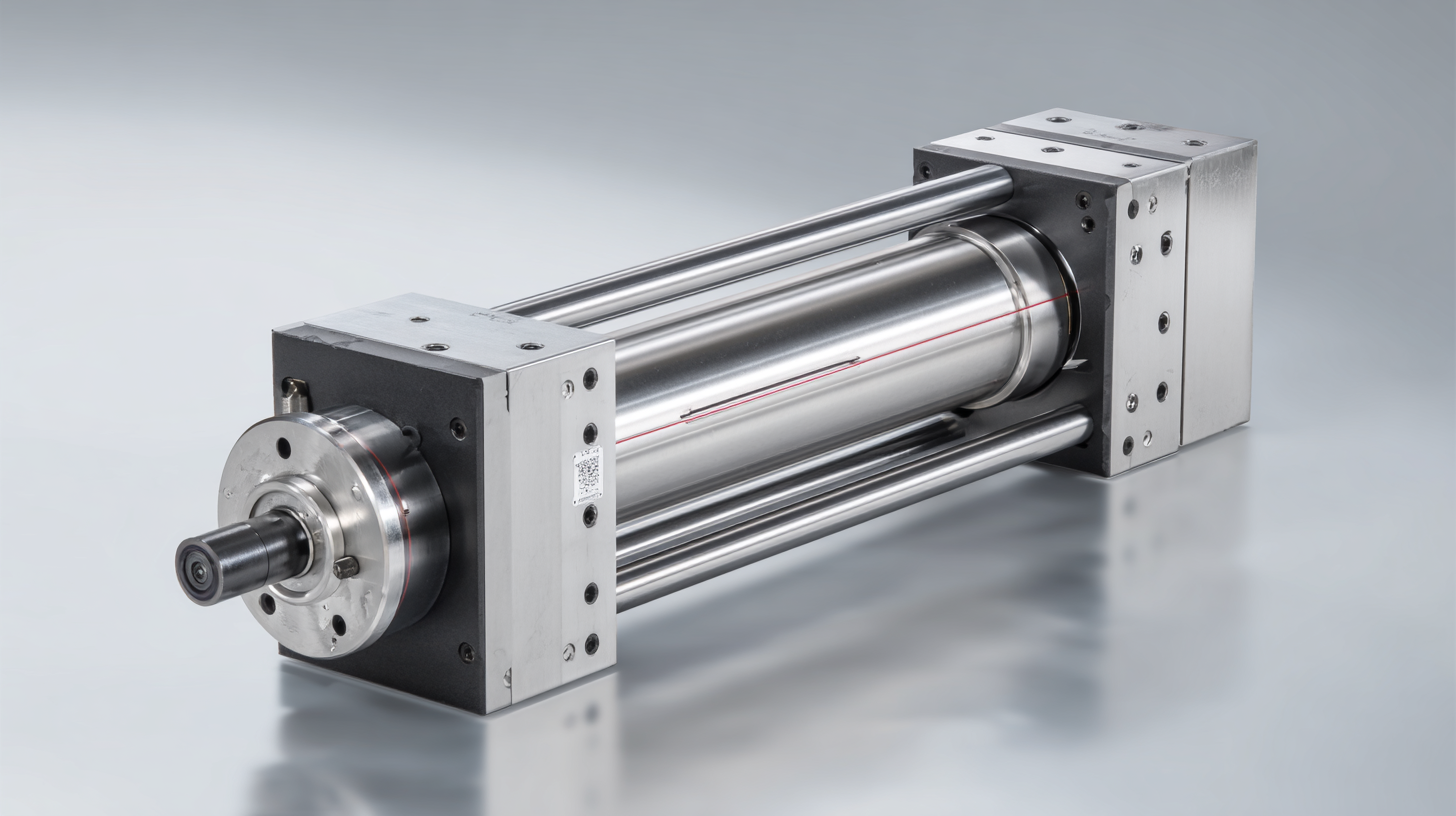

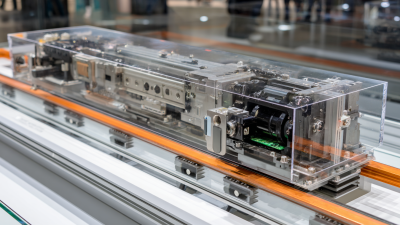

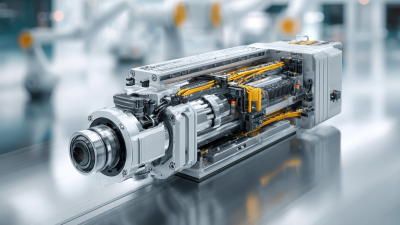

Cylindrical linear motors are transforming the landscape of automation by providing a range of advantages that enhance efficiency and precision in various industrial applications. These motors are characterized by their simplicity in design and their ability to produce linear motion without the need for complex mechanical components. This results in reduced maintenance and improved reliability, making them an ideal choice for automation systems that demand high performance and minimal downtime.

One of the key benefits of cylindrical linear motors is their flexibility in application. They can be easily integrated into various automation processes, allowing for seamless customization in production lines. This adaptability is crucial in a rapidly evolving industrial environment where demands for efficiency and responsiveness are constantly increasing. By harnessing the innovative capabilities of cylindrical linear motors, industries can unlock new possibilities and optimize their operations to meet contemporary challenges head-on.

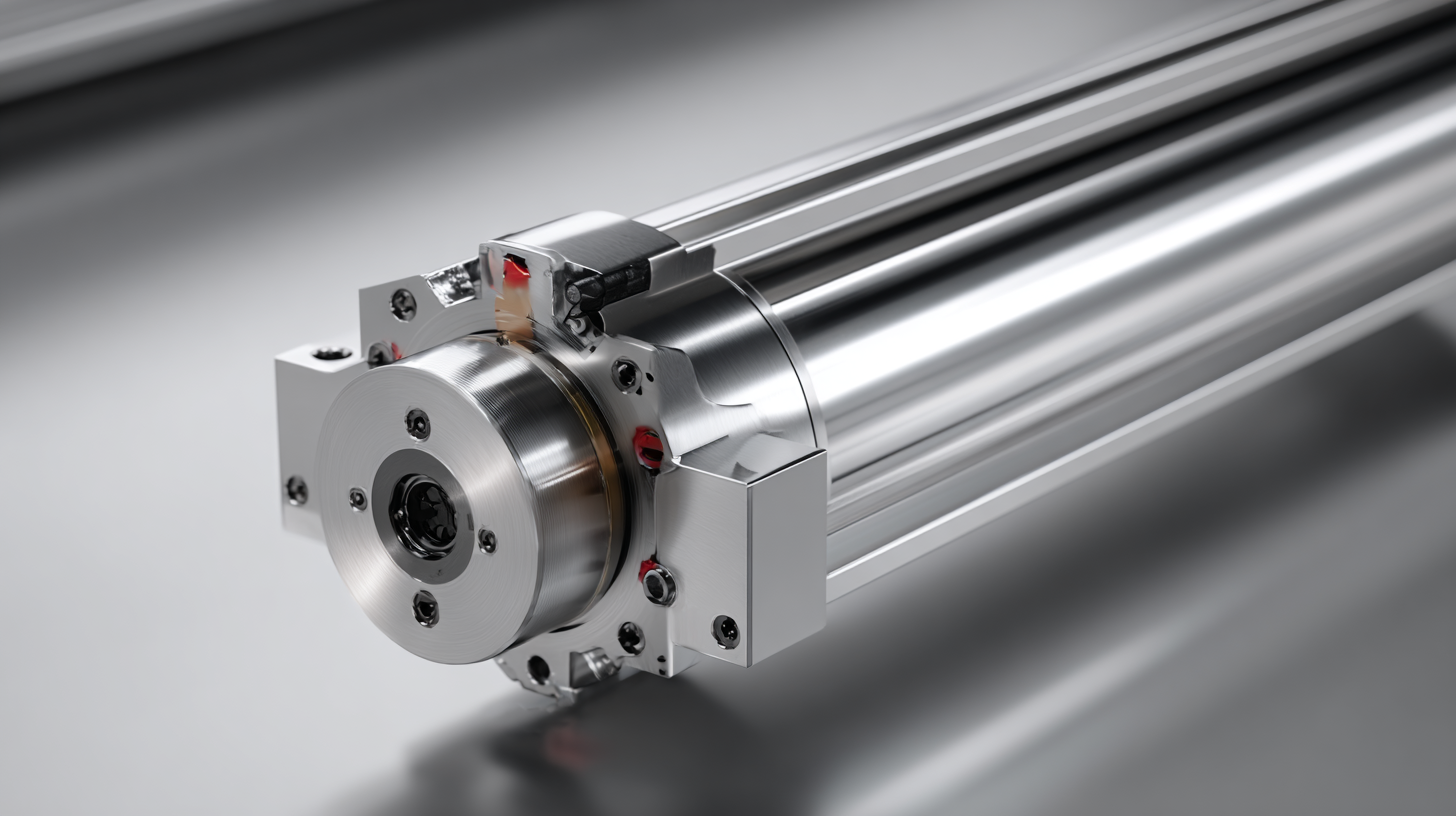

Cylindrical linear motors are revolutionizing automation across multiple industries by offering precise motion control and exceptional efficiency. In manufacturing, these motors are increasingly used in robotic systems that require rapid and accurate movements. Their design allows for direct drive applications, eliminating the need for mechanical linkages, which reduces wear and enhances reliability over time.

In the healthcare sector, cylindrical linear motors are finding significant applications in medical devices, such as advanced imaging systems and surgical robots. Their ability to provide smooth and repeatable motion is critical in environments where precision is paramount.

Additionally, in the logistics industry, these motors facilitate high-speed conveyor systems that ensure quick transportation and sorting of goods, contributing to streamlined operations and improved supply chain efficiency. The versatility of cylindrical linear motors positions them as a cornerstone of future automation endeavors across various sectors.

The advancement of cylinder motors, particularly cylindrical linear motors, is closely tied to the integration of intelligence that enhances their efficiency and performance. By employing artificial intelligence techniques in their design and optimization, manufacturers can significantly improve operational capabilities. AI facilitates more accurate predictive maintenance, allowing for timely interventions that not only increase uptime but also extend the lifespan of these motors.

Tips: When researching improvements in automation, consider the specific AI techniques that best suit your application. Machine learning algorithms can help optimize performance parameters and reduce energy consumption.

Furthermore, the use of intelligent control systems, such as those enhanced by deep reinforcement learning, adds another layer of efficiency. These systems dynamically adjust to varying conditions, thereby optimizing response times and ensuring that machinery operates within the most effective parameters.

Tips: Look into adaptive control strategies if you're aiming to elevate your automation processes. Such approaches can lead to substantial improvements in system responsiveness and accuracy, ultimately contributing to better overall efficiency.

| Motor Type | Max Force (N) | Efficiency (%) | Weight (kg) | Cooling System | Control Method |

|---|---|---|---|---|---|

| Cylindrical Linear Motor A | 250 | 89 | 15 | Air Cooling | Closed Loop |

| Cylindrical Linear Motor B | 300 | 92 | 18 | Liquid Cooling | Open Loop |

| Cylindrical Linear Motor C | 280 | 88 | 16 | Air Cooling | Closed Loop |

| Cylindrical Linear Motor D | 350 | 90 | 20 | Liquid Cooling | Closed Loop |

Cylindrical linear motors are revolutionizing automation by offering distinct advantages over traditional actuators. Unlike conventional systems that rely on mechanical linkages and gears, cylindrical linear motors provide direct drive capabilities. This eliminates mechanical losses and improves efficiency, leading to faster response times and increased precision in motion control. Additionally, these motors can handle higher speeds and longer stroke lengths, making them ideal for a variety of applications, from industrial automation to robotics.

When comparing cylindrical linear motors with traditional actuators, one notable difference is the design and maintenance requirements. Traditional actuators often require regular maintenance due to their mechanical components, which can wear out over time. In contrast, cylindrical linear motors have fewer moving parts, resulting in reduced wear and tear and lower maintenance costs. Furthermore, their compact design allows for more flexibility in system integration, making them a preferred choice in modern automation solutions. As industries continue to optimize their processes, the shift towards cylindrical linear motors reflects a significant advancement in actuator technology.

Cylindrical linear motors are poised to transform the landscape of automation, enhancing efficiency and precision across various industries. According to a report by MarketsandMarkets, the global linear motors market is projected to reach USD 5.3 billion by 2025, growing at a CAGR of 9.2% from 2020. This growth is largely driven by the increasing demand for automation in manufacturing, logistics, and assembly applications. The adoption of cylindrical linear motors provides key advantages, including higher speed, reduced maintenance, and improved energy efficiency, making them a compelling choice for modern automated systems.

Furthermore, the integration of cylindrical linear motors into robotics and mechatronics is expected to revolutionize production lines. As noted by ResearchAndMarkets, advancements in technology are leading to more compact and powerful linear motors, which are essential for high-precision tasks. The automotive and electronics sectors, in particular, are witnessing rapid innovations that leverage these motors for improved automation. With the convergence of Industry 4.0 and smart manufacturing, the role of cylindrical linear motors will only become more vital, setting the stage for unprecedented levels of operational excellence and productivity.

This bar chart illustrates the projected market growth of cylindrical linear motors in various industries from 2023 to 2028. The data shows an increasing trend in adoption, indicating their importance in the future of automation technologies.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.