Call Today: 916-259-1868

In today's rapidly evolving manufacturing landscape, the demand for higher efficiency and precision has propelled the adoption of advanced technologies, notably electric linear motors. According to a report by MarketsandMarkets, the global industrial automation market is projected to reach $295.6 billion by 2023, with electric linear motors playing a pivotal role in this transformation.

These motors are revolutionizing automation by offering advantages such as high-speed operation, excellent accuracy, and reduced maintenance needs compared to traditional systems. Their ability to deliver precise linear motion not only enhances productivity but also minimizes operational costs, making them an attractive option for manufacturers striving for a competitive edge. As industries increasingly shift towards automation and smart manufacturing, the implementation of electric linear motors is set to redefine performance benchmarks and drive innovation across various sectors.

Electric linear motors are transforming the landscape of automation in manufacturing by offering precision and efficiency that traditional systems cannot match. Understanding the basics of these motors is crucial for engineers who are navigating the complexities of motion control in automated environments. As highlighted in recent industry insights, the foundational principles of motion control are essential for developing effective automation strategies that maximize productivity while minimizing energy consumption.

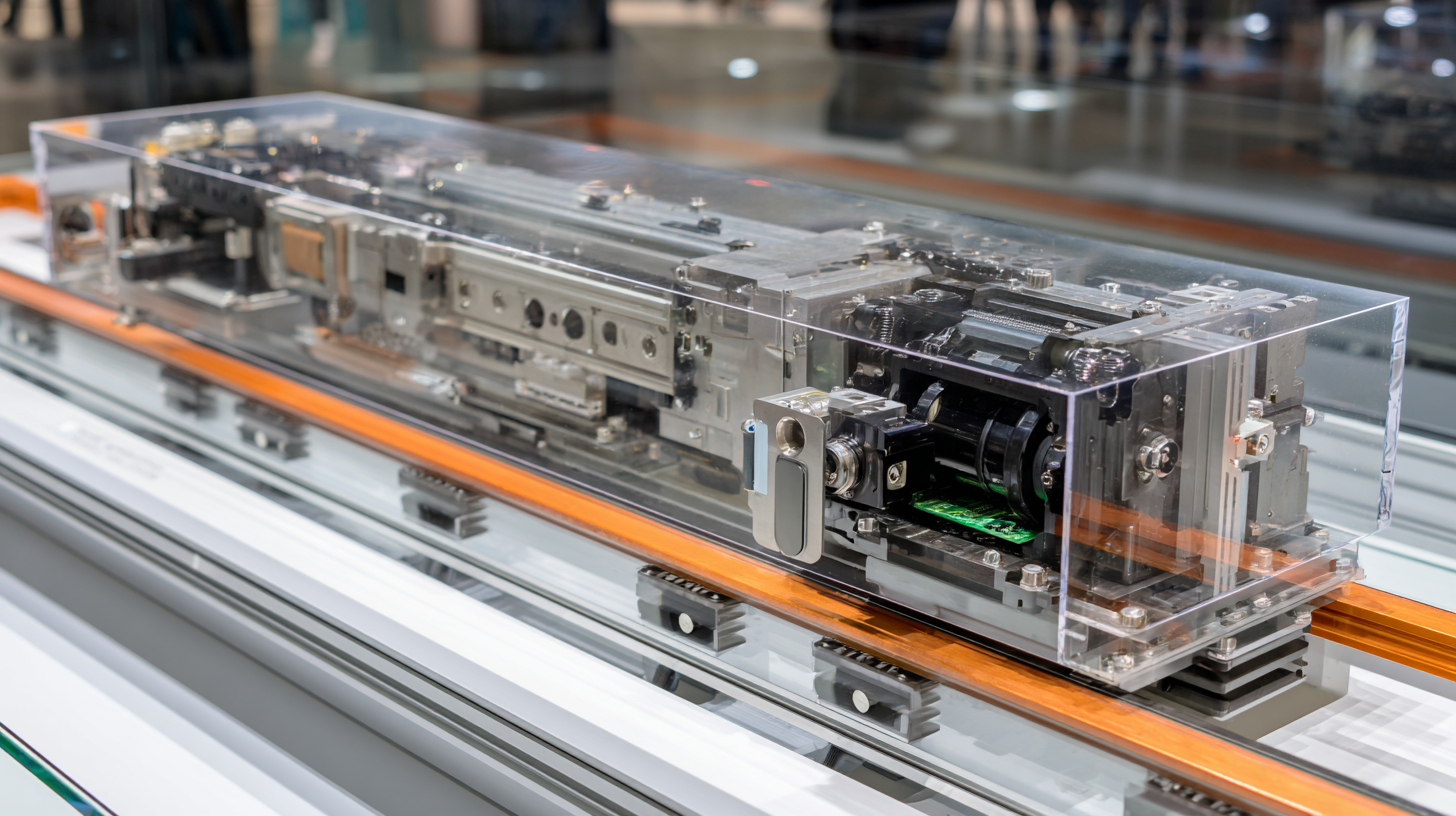

In 2022, the global market for electric linear actuators reached a valuation of $20.5 billion, illustrating the increasing reliance on these technologies within the manufacturing sector. The rise of smart factories, which digitize all aspects of production, further underscores the significance of integrating electric linear motors within advanced automation systems. These innovations not only improve operational efficiency but also facilitate better connectivity between discrete automation processes. As manufacturers strive to adapt to evolving demands, understanding how electric linear motors contribute to overall system performance becomes paramount.

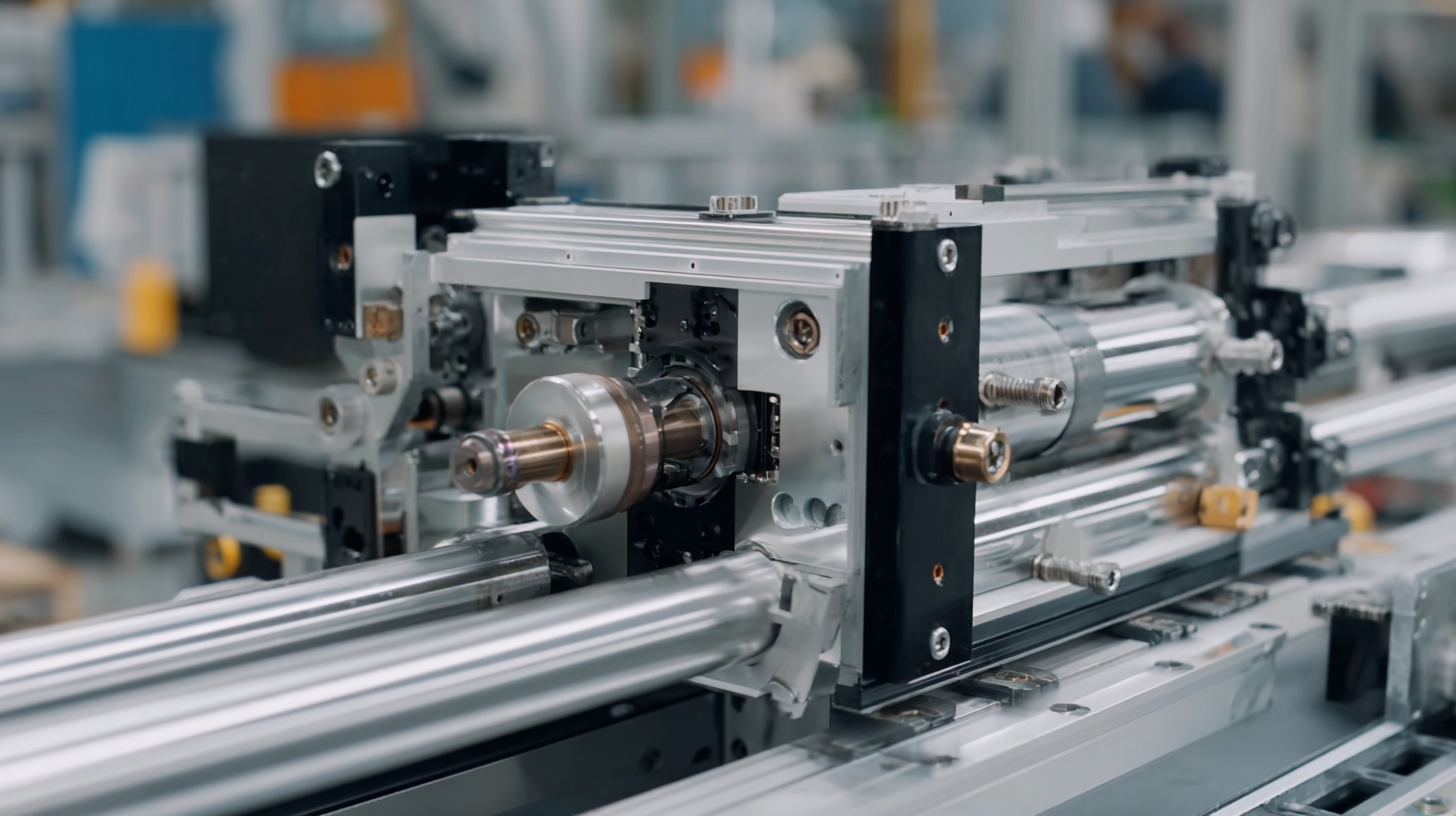

Electric linear motors are transforming the landscape of automation in manufacturing, thanks to their unique advantages over traditional linear motion systems. One of the key benefits is their precision. By providing direct drive motion, electric linear motors eliminate the need for mechanical components like gears and belts, which can introduce backlash and decrease accuracy. This precision not only enhances product quality but also allows for more complex and intricate manufacturing processes.

Electric linear motors are transforming the landscape of automation in manufacturing, thanks to their unique advantages over traditional linear motion systems. One of the key benefits is their precision. By providing direct drive motion, electric linear motors eliminate the need for mechanical components like gears and belts, which can introduce backlash and decrease accuracy. This precision not only enhances product quality but also allows for more complex and intricate manufacturing processes.

Tips for implementation: When integrating electric linear motors into your manufacturing operations, consider conducting a thorough analysis of your production workflows. Identify areas where precision and speed are critical, as these are the zones where electric linear motors can deliver the most significant improvements. Moreover, ensure that your team is trained on the latest technologies to maximize the benefits these systems offer.

Another crucial advantage of electric linear motors is their efficiency. They generally consume less energy compared to traditional systems, leading to lower operational costs. This efficiency not only supports sustainability initiatives but can also enhance overall throughput by reducing downtime associated with mechanical failures.

Tips for optimization: Regular maintenance and monitoring of the motors can help in sustaining their performance over time. Investing in predictive maintenance technology can further reduce costs by anticipating potential issues before they arise, ensuring continuous and efficient operation.

Electric linear motors are transforming the landscape of automation in manufacturing by providing unparalleled efficiency and precision. When implementing electric linear motors, it’s crucial to adopt best practices to fully leverage their advantages. According to a recent report from MarketsandMarkets, the global electric motor market is expected to grow from $121.87 billion in 2020 to $175.36 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.5%. This growth is driven by the increasing demand for automation in various sectors, showcasing the strategic importance of electric linear motors in modern manufacturing processes.

One of the best practices for implementing electric linear motors is to conduct a thorough assessment of the specific application requirements. Each manufacturing system has unique characteristics, and understanding these needs will aid in selecting the appropriate motor specifications. For instance, a study by the International Society of Automation indicates that the collaboration between engineers and motor manufacturers can lead to optimized performance and reduced downtime, resulting in up to a 25% increase in efficiency. Additionally, integrating advanced control systems can enhance the precision of operations, minimizing errors and maximizing throughput while ensuring the manufacturing process remains agile and responsive to changing demands.

| Application Area | Motor Type | Load Capacity (kg) | Speed (m/s) | Power Consumption (kW) | Efficiency (%) |

|---|---|---|---|---|---|

| Assembly Line | Linear Synchronous Motor | 100 | 1.5 | 0.75 | 90 |

| Packaging | Magnetic Linear Motor | 80 | 2.0 | 0.60 | 88 |

| Material Handling | Linear Induction Motor | 120 | 1.2 | 0.80 | 85 |

| CNC Machining | Servo Linear Motor | 150 | 1.0 | 1.00 | 92 |

| Conveyor Systems | Direct Drive Linear Motor | 200 | 2.5 | 1.25 | 95 |

Electric linear motors have become a focal point in modern manufacturing, providing unprecedented efficiency and precision. Numerous factories across various sectors have successfully integrated these motors, resulting in remarkable improvements in productivity and reduced downtime. For instance, an automotive manufacturer implemented electric linear motors in their assembly line, leading to a 30% increase in throughput while minimizing energy consumption. This transition not only improved operational efficiency but also contributed to a greener manufacturing process.

Tips for successful integration of electric linear motors include conducting a thorough needs assessment before implementation, ensuring compatibility with existing systems, and providing comprehensive training to the workforce. For example, a food processing plant that adopted electric linear motors for packaging saw significant gains by re-evaluating their workflow and using custom-designed tracks that optimized space and speed.

Another compelling case study involves a semiconductor fabrication facility that faced precision challenges. By switching to electric linear motors, they enhanced alignment accuracy and reduced defects by 25%. This transition underscores the importance of investing in advanced technologies to streamline operations and maintain high-quality standards. Engaging in continuous improvement practices will further amplify the benefits of these systems in manufacturing settings.

As Industry 4.0 continues to gain traction globally, the role of electric linear motors becomes increasingly pivotal in revolutionizing manufacturing automation. These motors, known for their precise control and high efficiency, are essential components in smart factories. They facilitate a seamless integration of the Internet of Things (IoT) and advanced robotics, significantly enhancing production lines' speed and flexibility. The demand for higher productivity and reduced downtime necessitates a shift from traditional motor systems to electric linear motors, which offer superior performance and reliability.

In Taiwan, the industrial computer industry is witnessing a remarkable transformation driven by these technological advancements. Companies are rapidly adopting electric linear motors to streamline operations and improve output. Industry leaders are focusing on developing smarter, interconnected systems that leverage data analytics and real-time monitoring to optimize processes. As businesses embrace these innovations, electric linear motors will play a crucial role in transitioning toward a more automated and intelligent manufacturing landscape, marking a significant step forward in the journey towards Industry 4.0.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.