Call Today: 916-259-1868

The evolution of motion control technologies has reached a pivotal moment with the rise of electric linear motors, heralding a new era of efficiency and precision. As industries increasingly seek to enhance productivity while reducing energy consumption, electric linear motors have emerged as a leading solution. According to a report by Allied Market Research, the global electric linear motor market was valued at approximately $845 million in 2020 and is projected to reach $1.5 billion by 2027, growing at a CAGR of 8.3%. This growth is driven by their ability to provide direct drive systems with minimal friction, high speed, and reliable positioning.

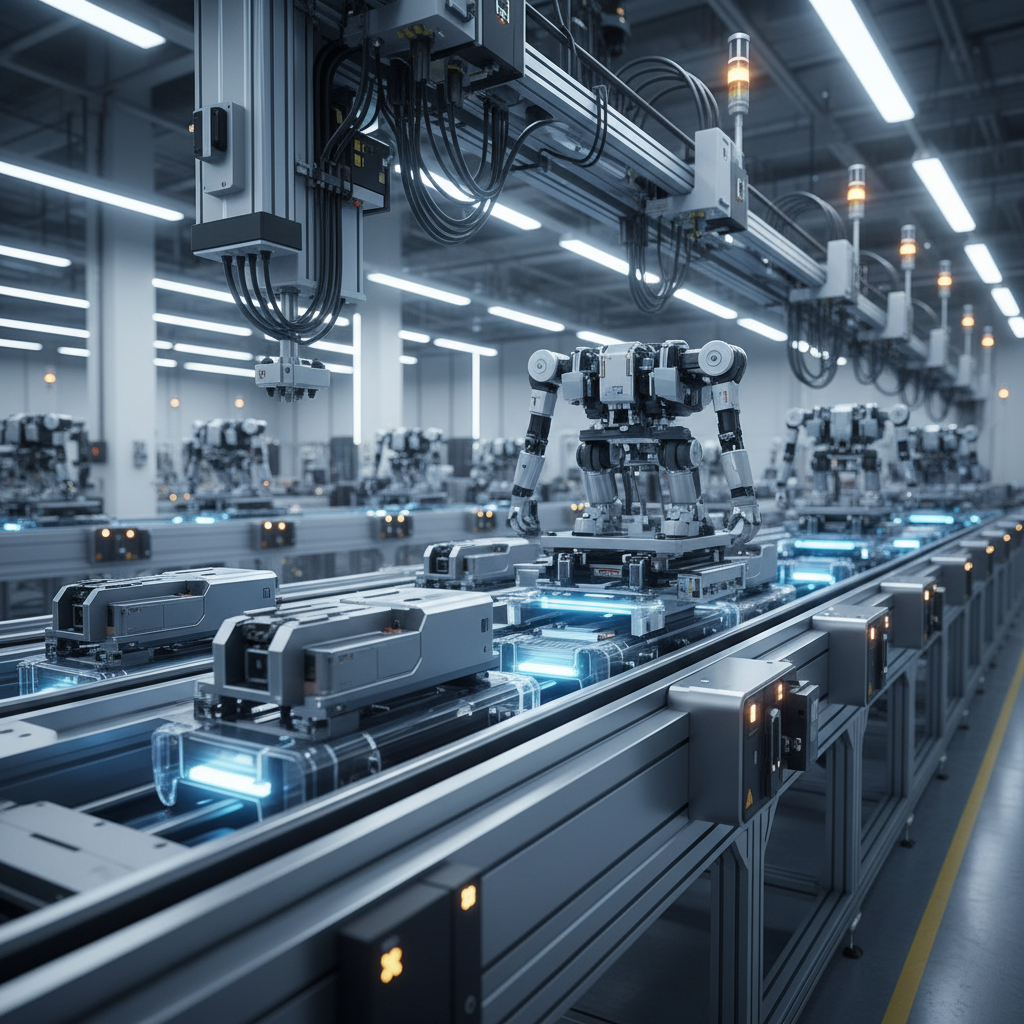

Electric linear motors are particularly advantageous in sectors such as manufacturing, robotics, and transportation, where the demand for high-performance motion control is paramount. A study conducted by the International Energy Agency (IEA) highlights that electric motors account for about 45% of the global electricity consumption in the industrial sector, making energy efficiency in motor technology a critical concern. By employing electric linear motors, companies can significantly decrease energy usage, optimize process times, and ultimately enhance their competitive edge in a rapidly evolving marketplace. As we delve deeper into the mechanics and benefits of electric linear motors, it becomes clear that they are not just an innovation; they represent the future of efficient and sustainable motion control.

The emergence of electric linear motors marks a transformative shift in motion control technology, reflecting significant market trends poised to reshape various industries by 2025. As companies increasingly seek to enhance efficiency and reduce operational costs, the demand for precise and reliable linear motion solutions has surged. With applications spanning from manufacturing automation to robotics, electric linear motors offer superior performance characteristics, including rapid acceleration, high precision, and reduced maintenance needs compared to traditional systems.

Projections for 2025 indicate a robust growth trajectory for the electric linear motor market, driven by advancements in technology and increasing adoption in sectors such as automotive, aerospace, and healthcare. Market analysts predict a compound annual growth rate (CAGR) that will be fueled by innovations such as improved energy efficiency and integrated smart technologies.

Moreover, as environmental concerns prompt a shift towards sustainable practices, electric linear motors present an eco-friendly alternative, minimizing energy consumption and waste. This convergence of factors underscores the pivotal role electric linear motors are set to play in the future of motion control, positioning them as the preferred choice for next-generation automation solutions.

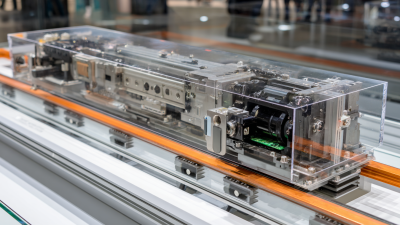

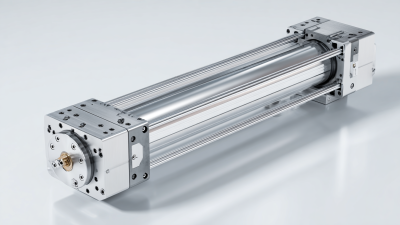

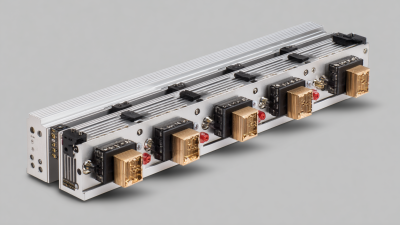

Electric linear motors represent a groundbreaking advancement in motion control technology, particularly when compared to traditional actuation systems. Unlike conventional systems that rely on rotary motors and complex mechanical linkages, electric linear motors deliver direct linear motion with high precision and minimal friction. This direct drive mechanism not only enhances speed and responsiveness but also reduces maintenance needs, making electric linear motors a more efficient choice for various applications.

One of the most significant efficiency gains is in energy consumption. Electric linear motors operate with a higher efficiency compared to their traditional counterparts, translating to lower operational costs. This improvement stems from their ability to eliminate the energy losses commonly found in gearboxes and other conversion systems. Industries that require high-performance motion control, such as manufacturing and robotics, greatly benefit from these advancements, enjoying the benefits of reduced energy bills while boosting productivity.

**Tips:** To maximize the advantages of electric linear motors, consider implementing them in applications that require precise positioning and high-speed operation. Additionally, regular monitoring of system performance can help identify areas for optimization, further enhancing efficiency and cost-effectiveness. Embracing smart control systems can also elevate the operational capabilities of electric linear motors, ensuring seamless integration into existing workflows.

The adoption of electric linear motors is set to transform several key industries in the next decade, driven by their efficiency, precision, and reduced maintenance requirements. In manufacturing, especially in automated assembly lines, electric linear motors offer rapid acceleration and precise positioning, which enhances productivity and product quality. Companies looking to improve operational efficiency are increasingly integrating these motors into robotic systems, enabling seamless and flexible manufacturing processes.

Similarly, the transportation sector is embracing electric linear motors for applications such as high-speed trains and maglev systems. These motors provide a smooth and efficient ride, significantly reducing energy consumption and operational costs. Additionally, the aerospace industry is exploring electric linear motors for their potential in improving the performance of aircraft systems, from landing gear to wing actuators. As these industries continue to innovate, the demand for electric linear motors is expected to surge, positioning them at the forefront of motion control technologies.

Recent advancements in electric linear motors have significantly enhanced their performance and reliability, positioning them as a critical component in motion control systems. A report by MarketsandMarkets indicates that the electric linear motor market is expected to grow from USD 1.8 billion in 2021 to USD 2.9 billion by 2026, reflecting a compound annual growth rate (CAGR) of 10.0%. This growth is largely driven by technological innovations such as improved magnetic materials and advanced digital control algorithms, which have bolstered the efficiency and precision of these motors.

Moreover, the rising demand for automation in industries such as manufacturing, logistics, and robotics further propels the development of electric linear motors. According to a study by Research and Markets, the integration of Industry 4.0 technologies is fueling a shift towards electric linear motors for applications that require high-speed, high-precision movements. These motors now offer enhanced features such as reduced maintenance requirements and increased energy efficiency, with some designs achieving energy savings of up to 30% compared to conventional systems.

As these technologies continue to evolve, electric linear motors will become increasingly vital for achieving optimal performance in modern industrial applications.

Electric linear motors are rapidly becoming a cornerstone of motion control technology, driven by their impressive sustainability and environmental benefits. Unlike traditional motors that rely on mechanical components, electric linear motors operate on a direct drive principle, minimizing friction and reducing wear and tear. This not only leads to longer service life and lower maintenance costs but also reduces energy consumption. By integrating these motors into manufacturing and automation processes, companies can significantly lower their carbon footprint while achieving superior performance.

Tip: To maximize the efficiency of electric linear motors, ensure proper alignment and installation. This can prevent unnecessary energy losses and extend the life expectancy of the motor.

Additionally, electric linear motion control solutions can facilitate the use of renewable energy sources. As industries shift towards greener operational practices, the high efficiency of electric linear motors allows for seamless integration with solar and wind energy systems. By harnessing these clean energy sources, companies can achieve sustainable production methods, further contributing to environmental conservation.

Tip: Regularly monitor and optimize power settings according to load requirements to enhance energy efficiency and reduce overall costs.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.