Call Today: 916-259-1868

Cylindrical linear motors represent a significant advancement in the field of motion control technology. These motors are designed for precise, direct drive applications, offering high efficiency and reliability. According to a report by Research and Markets, the global market for linear motors is projected to grow at a CAGR of 7.5% from 2021 to 2026. This growth is driven by increased automation in various sectors, including manufacturing and robotics.

Dr. Emily Chen, an industry expert on linear motor technology, states, “Cylindrical linear motors are pivotal in applications where speed and precision are paramount.” This highlights the importance of understanding how these motors function. The cylindrical design allows for a compact form factor, making them suitable for confined spaces.

While cylindrical linear motors offer numerous benefits, there are still challenges to address. For example, their integration can be complex and may require advanced control systems. Regular maintenance is crucial to ensure optimal performance. Awareness of these factors is essential for industries looking to adopt this technology effectively.

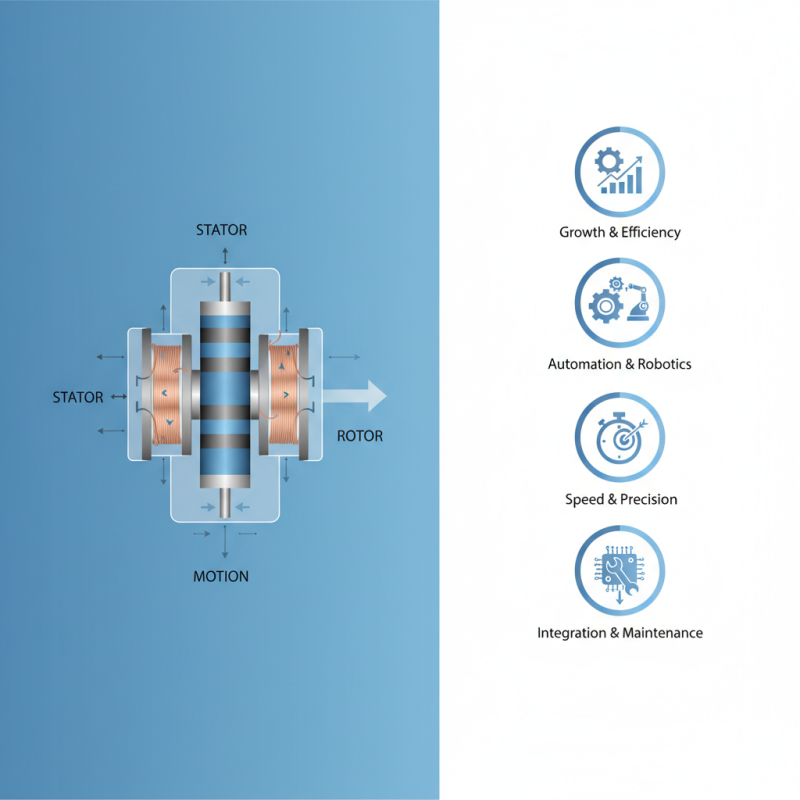

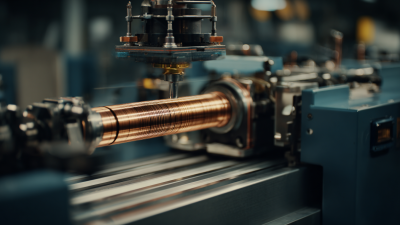

A cylindrical linear motor is an electromechanical device that converts electrical energy into linear motion. It consists of a cylindrical stator and a moving component. The stator contains coils that create a magnetic field when electricity flows through them. This magnetic field interacts with the moving part, generating motion along a linear path.

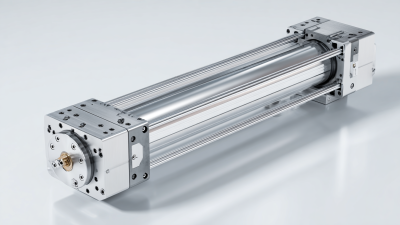

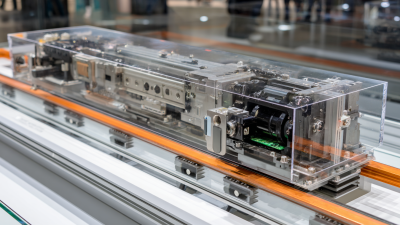

Unlike traditional motors, a cylindrical linear motor provides direct linear drive. This design improves efficiency and response time. Users can find this technology in various applications, from industrial automation to transport systems. The simplicity of the design allows for compact integration, saving space in machinery. However, the complexity of the control system can pose challenges.

One may encounter limitations when incorporating these motors into specific designs. Temperature management can be an issue due to heat generation. Additionally, wear and tear on the components can affect performance over time. Understanding these factors is essential for effective usage and implementation. Continuous improvement and innovation are necessary to overcome these challenges.

| Parameter | Description |

|---|---|

| Type | Cylindrical Linear Motor |

| Construction | Consists of a cylindrical stator and a moving slider |

| Operating Principle | Uses electromagnetic forces to generate linear motion |

| Applications | Robotics, CNC machines, and conveyor systems |

| Advantages | High precision, high speed, and low maintenance |

| Limitations | Cost and size considerations |

| Typical Force Output | Ranges from a few Newtons to several hundred Newtons |

| Control Method | Closed-loop control for precise motion control |

Cylindrical linear motors are fascinating devices. They convert electrical energy directly into linear motion. This mechanism is efficient and precise. But, how do they operate? The basic principle involves electromagnetic forces.

Coils generate a magnetic field when electricity flows through them. This field interacts with permanent magnets in the motor.

The alignment of the coils and magnets is crucial. Misalignment can lead to inefficiencies. The motion occurs when the magnetic field exerted by the coils pulls or pushes the attached components. For instance, the cylindrical shape allows smooth motion over a defined path. However, the design must be carefully engineered to reduce friction and wear.

Cooling is another concern in operation. High temperatures can affect performance. Regular monitoring is necessary to ensure optimal function. Sometimes, users may overlook these aspects. This oversight leads to increased maintenance costs. A better understanding of these operating principles can improve efficiency in various applications.

Cylindrical linear motors are fascinating devices used in various applications. They convert electrical energy into linear motion. Understanding their key components can shed light on their functionality.

One critical element is the stator, which contains coils that generate a magnetic field. This field interacts with the rotor. The rotor is equipped with permanent magnets. Together, these parts create motion. A report by the International Electromechanical Society noted that cylindrical linear motors can achieve speeds up to 10 meters per second. That's impressive, yet reliability issues can arise if not properly designed.

Another essential feature is the encoder. This device provides feedback on the rotor's position. Accurate positioning is crucial for precision tasks. However, encoders can sometimes fail or drift over time. Regular maintenance is essential for optimal performance. Lastly, the cooling system is vital for preventing overheating. It can affect the lifespan of the motor. Studies indicate that neglecting cooling can reduce efficiency by 15% or more. This highlights the importance of regular checks.

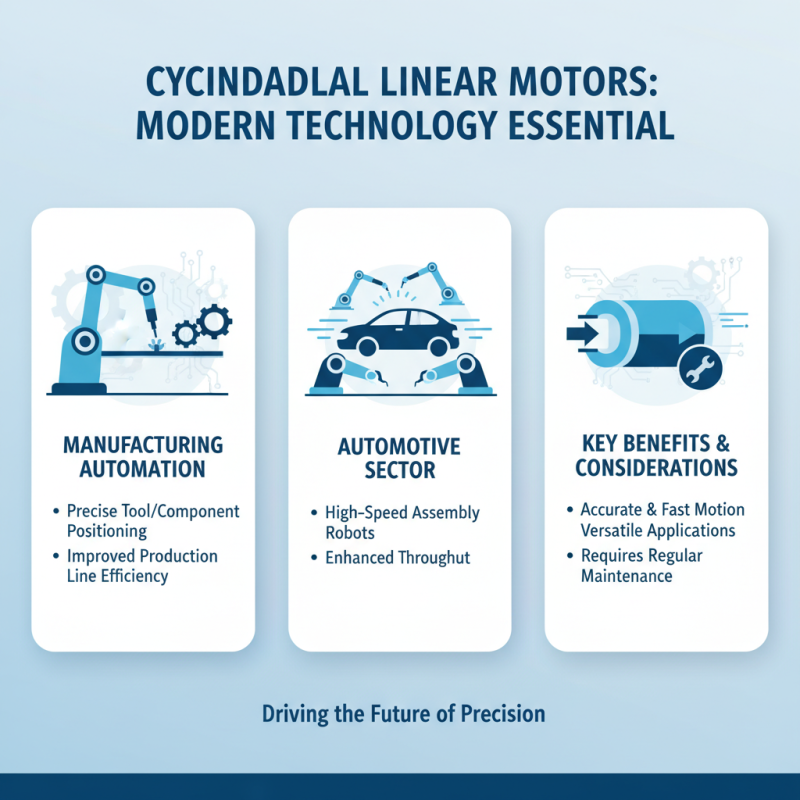

Cylindrical linear motors have diverse applications across various industries, making them essential for modern technology. In manufacturing, these motors drive precise movement in automation systems. They enable accurate positioning of tools and components, improving efficiency in production lines. In the automotive sector, they support assembly robots that require high-speed operations. These motors enhance throughput, but they may also necessitate regular maintenance to keep them operating smoothly.

In the medical field, cylindrical linear motors play a crucial role in medical imaging machines. They help position imaging equipment accurately, ensuring high-quality results. This precision is vital for diagnostics. However, the complexity of these motors can sometimes lead to issues that require troubleshooting. In logistics, cylindrical motors facilitate automated guided vehicles. These vehicles are used for transporting materials within warehouses. They increase speed and reliability but can face challenges in navigation, especially in crowded spaces.

In aerospace, these motors assist in controlling various mechanisms in aircraft. Their lightweight and compact design make them suitable for such applications. Yet, they require careful integration into existing systems. Each industry faces unique challenges, but the versatility and performance of cylindrical linear motors continue to drive innovation.

Cylindrical linear motors offer unique benefits and some drawbacks. One key advantage is their compact design. They can fit in tight spaces. This makes them ideal for applications where space is a premium. Their straightforward structure also ensures easy installation and maintenance. Many engineers appreciate this simplicity.

However, there are drawbacks to consider. Heat generation can be a concern. Excessive heating may reduce efficiency. Moreover, cylindrical motors can be sensitive to misalignment. This could lead to increased wear and tear over time. Users should be aware of these factors.

Tips: Always consider the environment where the motor will operate. Proper alignment is crucial for longevity. Regular maintenance can help prevent overheating. Make a checklist for inspections. This can save you from costly replacements.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.