Call Today: 916-259-1868

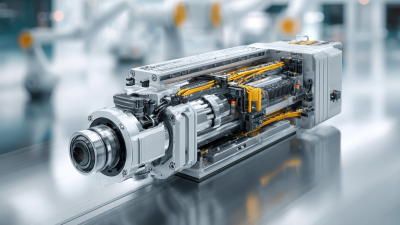

As the world continues to advance towards automation and precision engineering, the role of compact linear motors has become increasingly pivotal across various industries. These innovative devices not only promise enhanced performance but also cater to the growing demand for compact and efficient solutions in applications ranging from robotics to medical equipment. With numerous advancements on the horizon, 2025 is poised to witness significant developments that push the boundaries of what compact linear motors can achieve.

This article delves into the top 10 compact linear motors to watch in 2025, highlighting the latest innovations and their potential applications. With an emphasis on technological breakthroughs and performance enhancements, we explore how these motors are set to streamline operations, reduce footprint, and improve reliability in diverse environments. By examining both established players and emerging technologies in the compact linear motor space, we aim to provide insights into the future landscape of this dynamic field. As industries evolve and embrace new possibilities, staying informed about these advancements will be crucial for engineers, designers, and decision-makers alike.

As the demand for precision motion control escalates, compact linear motors are carving a niche in various applications for 2025. Notably, there is a surge in compact flexible linear stepping motors, designed to adapt dynamically to bending, twisting, and stretching, making them ideal for wearable and mobile technologies. This innovative approach is revolutionizing sectors like healthcare and consumer electronics, where space and weight constraints are paramount.

In the broader market landscape, the stack stepper motors segment is projected to soar from USD 591.1 million in 2025 to USD 1,028.9 million by 2035, reflecting a significant CAGR of 5.6%. This growth underscores the increasing reliance on advanced automation across industries, particularly in logistics, where micromotors play a critical role in enhancing operational efficiency.

**Tips:** When considering compact linear motors for your applications, prioritize those with integrated motor technology for improved performance. Additionally, explore flexible actuator options to leverage their versatility in emerging technology sectors. Lastly, staying updated with market forecasts can help in strategic planning for future investments.

| Motor Type | Force Output (N) | Speed (m/s) | Stroke Length (mm) | Applications |

|---|---|---|---|---|

| Linear Servo Motor | 200 | 2.5 | 150 | Robotics, CNC Machining |

| Voice Coil Motor | 50 | 1.2 | 100 | Optical Equipment, Industry Automation |

| Ironless Linear Motor | 100 | 3.0 | 200 | Pick and Place Systems, Packaging |

| Flat Motor | 80 | 2.0 | 120 | Medical Devices, 3D Printers |

| Slotless Linear Motor | 120 | 2.8 | 170 | Semiconductor Equipment, Laser Systems |

| Magnetic Levitation Motor | 150 | 4.0 | 300 | Transportation, Linear Elevators |

| Piezoceramic Linear Motor | 30 | 0.5 | 60 | Aeronautical Applications, Micro Positioning |

| Synchronous Linear Motor | 250 | 5.5 | 400 | Automated Guided Vehicles, Material Handling |

| Linear Stepper Motor | 75 | 1.0 | 90 | Textile Machines, Labeling Machines |

| Hybrid Linear Motor | 140 | 2.8 | 125 | Food Processing, Pharmaceutical Machines |

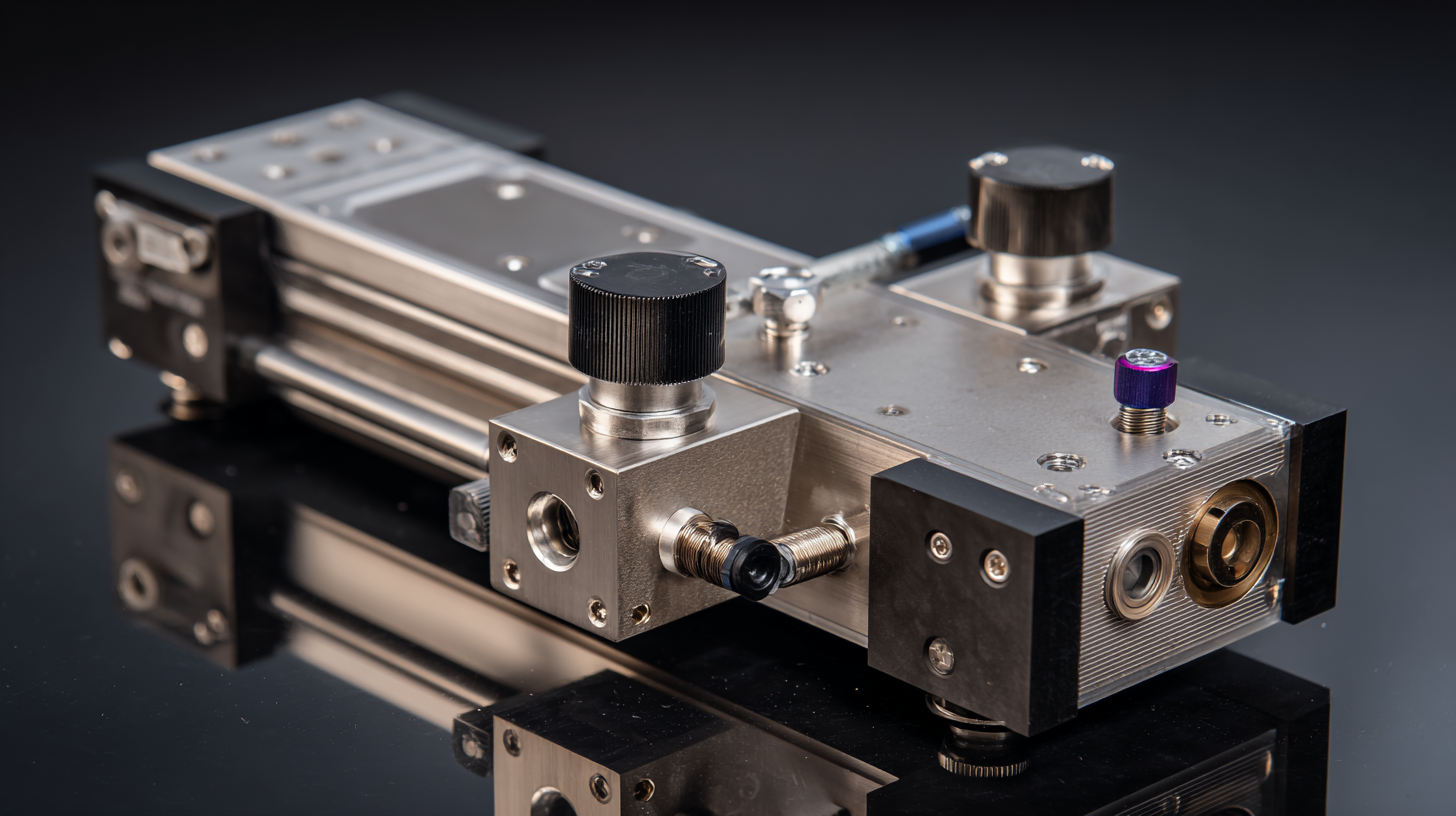

The evolution of compact linear motors is driven by key innovations that enhance their performance and broaden their applications across various industries. One standout development is the integration of advanced materials, such as lightweight composites and high-performance magnets. These materials not only reduce the overall weight of the motors but also improve their efficiency and power density, allowing for faster and more precise movements in compact designs.

Additionally, advancements in control algorithms and digital technology are revolutionizing how compact linear motors operate. The implementation of smart sensing and feedback systems allows for real-time adjustments, optimizing performance based on operational conditions. This adaptability not only enhances reliability but also extends the lifespan of the motors, making them suitable for demanding applications in robotics, automation, and medical devices. As these innovations continue to progress, the capabilities of compact linear motors are set to significantly expand, positioning them as critical components in the future of technology.

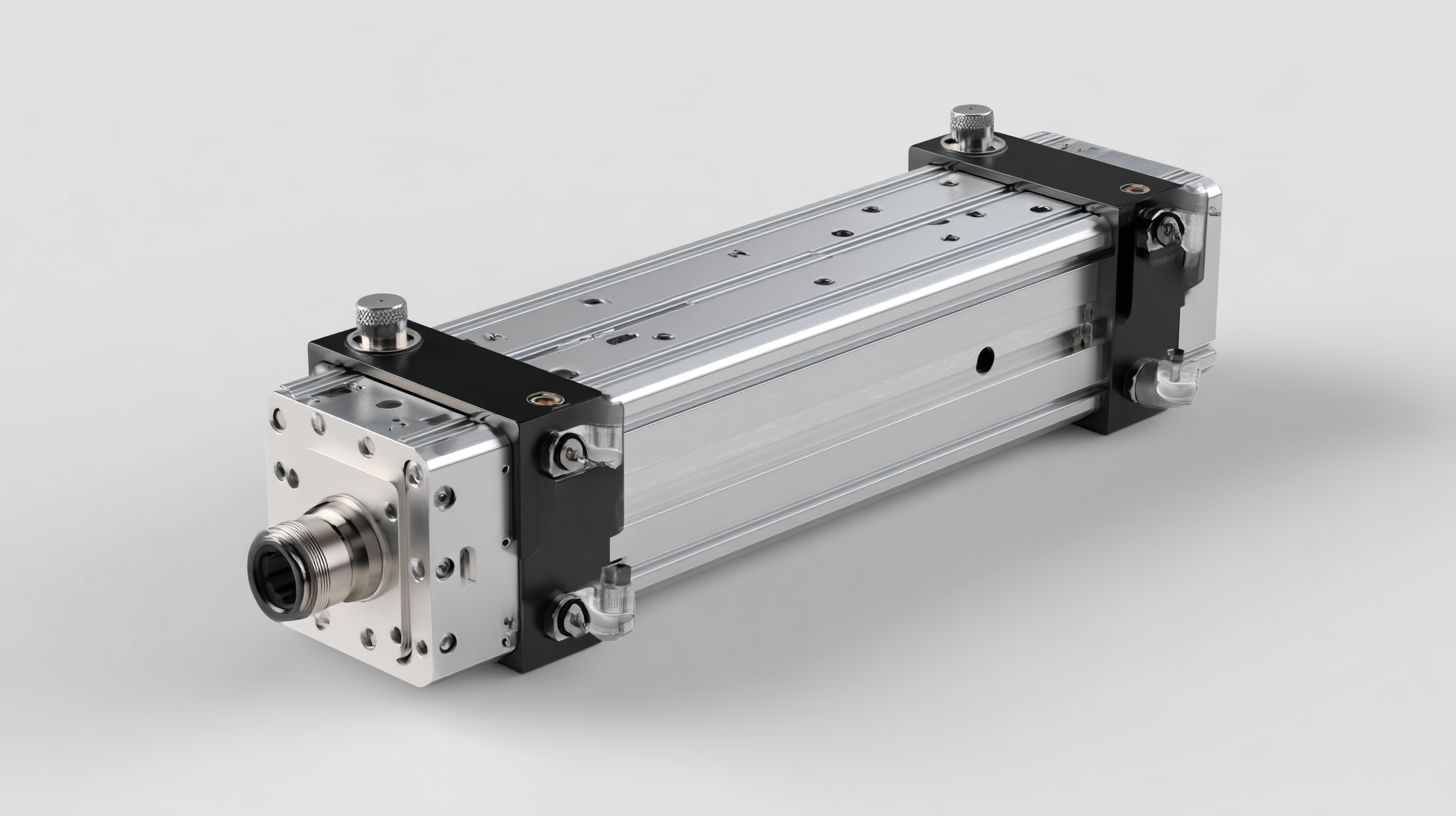

Compact linear motors are revolutionizing various industries by offering precise motion control in a compact form factor. Their applications range from robotics and automation to medical devices and semiconductor manufacturing. In robotics, for example, these motors enhance the performance of robotic arms, enabling smooth and accurate movements essential for assembly lines and precision tasks. Their ability to deliver fast acceleration and high repeatability makes them ideal for applications requiring intricate motion profiles.

In the medical field, compact linear motors are increasingly utilized in imaging systems and surgical equipment. These motors provide the necessary precision to control movements in MRI machines and surgical robots, improving diagnostic accuracy and patient outcomes. Additionally, the semiconductor industry leverages these motors for wafer handling and inspection processes, where the need for speed and accuracy is crucial. As advancements in technology continue, the demand for compact linear motors in diverse applications is set to grow, promoting innovation and efficiency across multiple sectors.

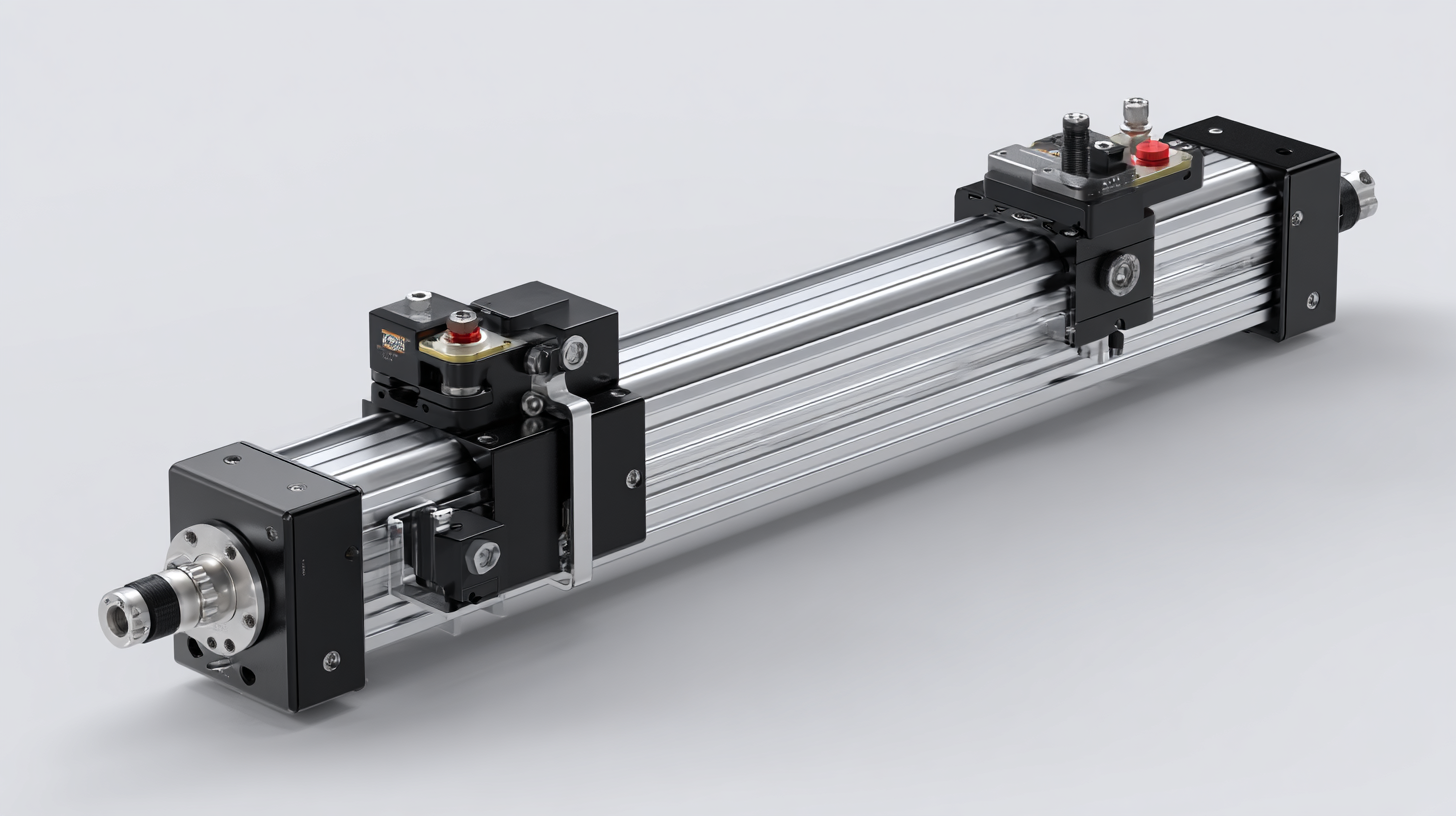

As the demand for precision and efficiency increases across various industries, compact linear motors are poised to play a significant role in future applications. A comparative analysis of leading compact linear motor manufacturers reveals that companies like Siemens, Beckhoff, and Yaskawa are at the forefront of innovation. According to a recent industry report, the compact linear motor market is projected to reach $2.5 billion by 2025, driven by advancements in automation and robotics. Siemens' latest models emphasize energy efficiency and reduced footprint, while Beckhoff focuses on integration with IoT technologies, enhancing overall system performance.

When selecting a compact linear motor, consider the specific application requirements such as load capacity and speed. This information is crucial, as a study indicates that a mismatch in motor specifications can lead to a 20% decrease in system efficiency. Additionally, manufacturers are increasingly offering customizable solutions to meet diverse industrial needs.

One tip for optimizing the use of compact linear motors is to invest in advanced control systems that enable sophisticated motion planning and dynamic response behaviors. This not only enhances overall operation but also extends the lifespan of the equipment. Furthermore, staying updated with the latest industry trends and innovations can significantly improve project outcomes and cost efficiency.

As we look toward 2025 and beyond, the compact linear motor market is poised for significant evolution driven by sustainability and efficiency in design. Manufacturers are increasingly focusing on creating motors that not only deliver high performance but also minimize environmental impact. Innovative materials and advanced manufacturing techniques are being implemented to enhance energy efficiency, reducing waste and lowering carbon footprints. This commitment to sustainable practices is becoming a key differentiator as companies strive to meet regulatory standards and consumer demand for eco-friendly solutions.

In parallel, the financial enterprise performance management (FCPM) software market is expected to reach impressive growth, with a projected market size of approximately $215.06 billion by 2032. This growth reflects the increasing need for organizations to streamline operations through robust performance management tools. Similarly, the electric vehicle traction motor market is witnessing explosive growth, predicted to swell from $632.06 million to over $2.23 billion by 2031, highlighting a compound annual growth rate of 52.2%. Such trends underscore a broader shift in industries toward electrification and efficiency, echoing the priorities driving innovation in compact linear motors.

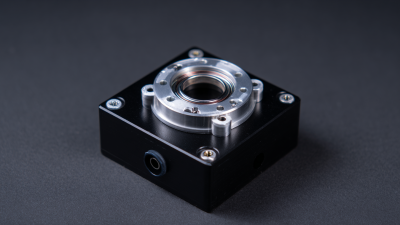

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.