Call Today: 916-259-1868

Choosing the right electric linear motor for your project can be complex. Industry expert Dr. Helen Carter states, “Selecting the correct motor is crucial for efficiency.” Her insight highlights the importance of making informed decisions.

Electric linear motors come in various types and sizes. Each option has unique features suited for different applications. Whether working on automation, robotics, or manufacturing, understanding your specific needs is vital.

Many projects suffer from mismatched motor selections. This can lead to inefficiency and increased costs. Take the time to analyze your requirements carefully. Reflect on the importance of alignment between motor capability and project demands. Knowing that the electric linear motor you choose will greatly impact your project's success can guide a more thoughtful selection process.

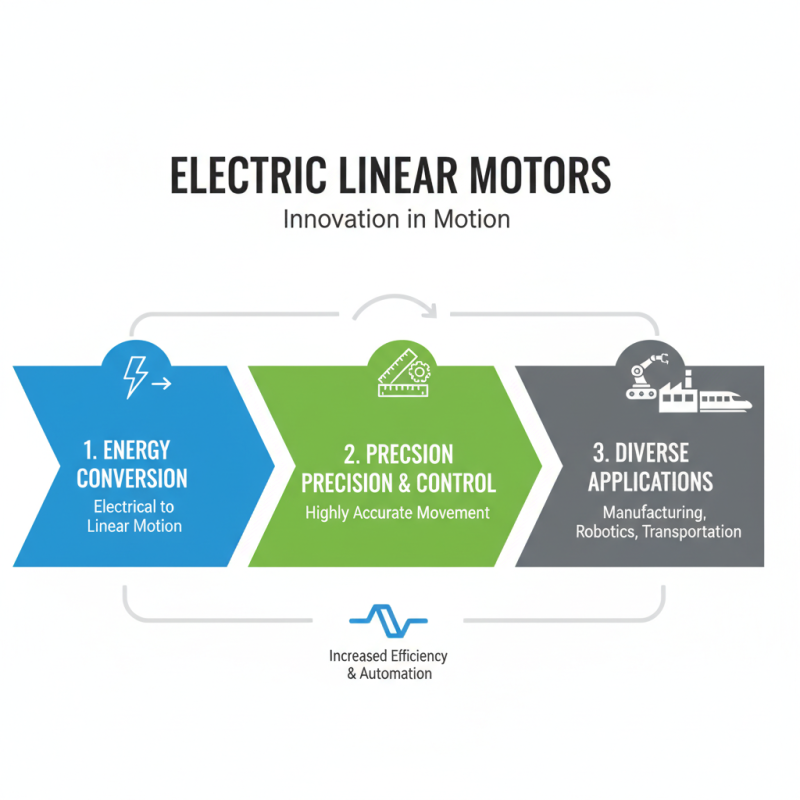

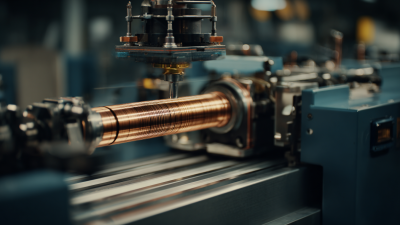

Electric linear motors are unique devices. They convert electrical energy into linear motion. This motion can be very precise. Many applications benefit from this technology.

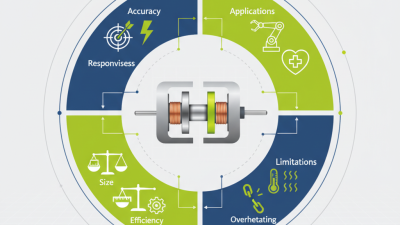

There are several types of electric linear motors. For instance, there are voice coil motors. They are compact and efficient. Then, there are stepper motors. They provide controlled movement at different speeds. Each type has its strengths and weaknesses. Understanding these can be challenging. It’s essential to analyze your project needs closely.

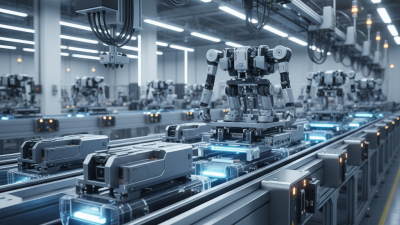

Applications vary widely. From automation in factories to robotics, the use cases are diverse. Some projects require fast response times. Others need high load capacity. It can be tough to find the perfect match. Engaging with professionals can provide better insights. However, sometimes their recommendations may not fit all unique requirements. Thus, it's crucial to assess the specifics of your project while choosing a motor.

When selecting an electric linear motor, key specifications require attention. The load capacity is crucial. Many applications demand motors that can handle various weights. Data from industry reports suggest that motors with a capacity of over 1000 N are common in automation settings. Consider the speed requirements too. Motors typically range from 0.1 m/s to 5 m/s. Your project's needs will dictate the best choice.

Another important factor is the precision of the motor. Applications may require different levels of accuracy. Devices like CNC machines often use motors with an accuracy of ±0.01 mm. If your task involves high precision, double-check these specifications. Additionally, the duty cycle matters; continuous operation might necessitate a motor rated for such use.

**Tips:** Always verify the installation space, as it directly impacts the motor's effectiveness. Also, consult professionals if uncertain about specifications. It saves time and resources later.

Evaluate your project thoroughly. Each application differs, and assumptions can lead to poor choices. Pay attention to thermal management too. Some motors require cooling, especially during demanding cycles. Look for a balance between performance and durability to avoid unexpected failures.

| Specification | Details |

|---|---|

| Force Output | 100 N to 5000 N |

| Stroke Length | 50 mm to 1000 mm |

| Speed | Up to 500 mm/s |

| Power Consumption | 10 W to 600 W |

| Weight | 1 kg to 50 kg |

| Ingress Protection | IP54 to IP67 |

| Control Type | Closed-loop or Open-loop |

When choosing an electric linear motor, performance metrics are key. Focus on force, speed, and stroke length. Each of these factors affects the motor's overall capabilities. For instance, the required force depends on the load the motor will move. Underestimating this can lead to inefficient operation. A motor that lacks sufficient force may struggle, or worse, stall.

Speed is another crucial element. It determines how fast the motor can complete tasks. For applications requiring quick movements, a higher speed rating is essential. However, achieving high speeds can lead to mechanical wear. Thus, striking a balance is vital. Also, consider the stroke length. This measurement shows how far the motor can extend and retract. A longer stroke length may seem better, but it could complicate system design.

It's easy to overlook these details when in a rush. Many projects suffer due to mismatched performance metrics. Reflecting on your specific needs can save time later. Ask yourself: what is the primary function? What limitations exist within the design? Tuning these metrics to the project will enhance final results and performance.

When selecting an electric linear motor, environmental factors play a significant role. The first consideration is the temperature range. Motors operate differently in extreme heat or cold. For instance, high temperatures may affect insulation, leading to failures. It's crucial to know the operating environment and its variations. If the motor will face high humidity, special coatings help prevent corrosion.

Dust and debris exposure is another factor. In clean rooms, standard motors suffice. However, in harsh environments, sealed designs are essential. These motors prevent particles from entering and damaging internal components. It’s easy to overlook this aspect, but it can save significant repair costs later.

Finally, consider vibration and shock levels. Certain applications involve heavy machinery where motors face constant movement. This can lead to motor wear over time. A robust motor design can handle these stresses. Be aware that a motor that works well in one place might fail in another. Research and adapt your choice accordingly.

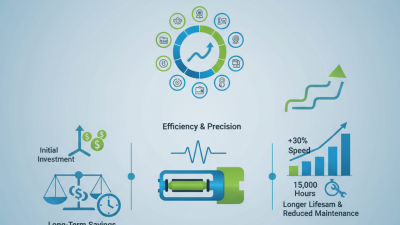

When budgeting for electric linear motors, understanding costs is crucial. According to a recent industry report, costs can vary greatly. Standard models may range from $100 to over $1,000. This wide range makes it essential to align motor choice with project needs.

Consider the total cost of ownership. Maintenance, energy consumption, and lifespan impact long-term expenses. For example, a motor with higher efficiency may cost more upfront but save in energy bills. Estimates suggest that energy-efficient motors can lower operating costs by up to 25% over time. However, selecting the most cost-effective option can be tricky. Without proper analysis, projects may exceed their budgets.

Flexibility in design is equally important. Some designs demand a specific type of motor, which can drive costs higher. A small oversight can lead to purchasing an oversized or undersized unit. Inadequate planning might lead to unexpected expenses, hampering project success. Evaluating multiple factors ensures that projects remain financially viable while meeting technical requirements.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.