Call Today: 916-259-1868

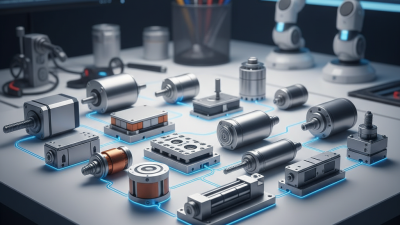

Choosing the right linear direct drive can be challenging. There are numerous options available. Each type has unique features and advantages. Understanding your specific needs is crucial.

Consider factors such as speed, torque, and application. Does your project require high precision or powerful performance? Each aspect significantly impacts the functionality of your linear direct drive. Sometimes, it is easy to overlook these factors.

Additionally, the cost versus performance balance is vital. A higher price tag does not always mean better quality. Making the best choice requires careful thought and research. Reflecting on your priorities can lead you to the ideal solution. It's worth taking the time to evaluate your options.

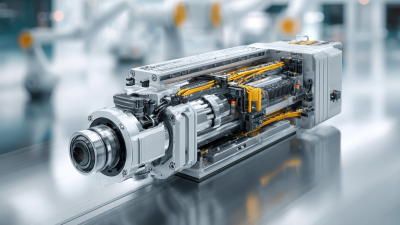

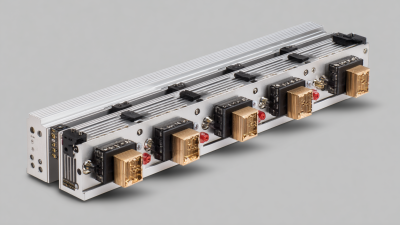

Choosing the right linear direct drive involves understanding its core principles. These drives use a linear motor for movement. This design allows for precise positioning and speed control. With no gears or belts, mechanical wear is minimal. This can lead to a longer lifespan and less maintenance.

When considering a drive, focus on load capacity and stroke length. Make sure it matches your project requirements. A small error in specifications can lead to major issues. Think about the environment, too. Factors like temperature and humidity affect drive performance.

Tip: Always test your motor in real scenarios. Simulations are helpful, but nothing beats hands-on experience.

Look for drives with flexible control systems. They can adapt to various applications. Not all setups will be straightforward. You may face compatibility issues. It's important to communicate with your suppliers or engineers early.

Tip: Review all documentation thoroughly. Sometimes, the information can be overwhelming. Take notes, and don’t hesitate to ask questions. A small detail can have a big impact on your success.

When evaluating power requirements for a linear direct drive system, it’s important to match the output with your specific needs. Identify the load that the system will carry. This includes understanding the weight and type of materials involved. Power ratings should align closely with these requirements. Overestimating can lead to higher costs and energy waste.

Consider the peak and continuous power needs. These are critical, especially in applications requiring variable speeds. A mismatched system can lead to inefficiencies or even failure. Think about the environment as well; some settings may require systems that can handle extra stress or temperature changes.

Tips: Always calculate possible fluctuations in power requirements. This helps prevent unexpected overloads. Examine your working environment to ensure that the drive can operate safely and efficiently. Adjust to the actual usage patterns over time for optimal performance. Recognizing potential limitations can lead to better choices.

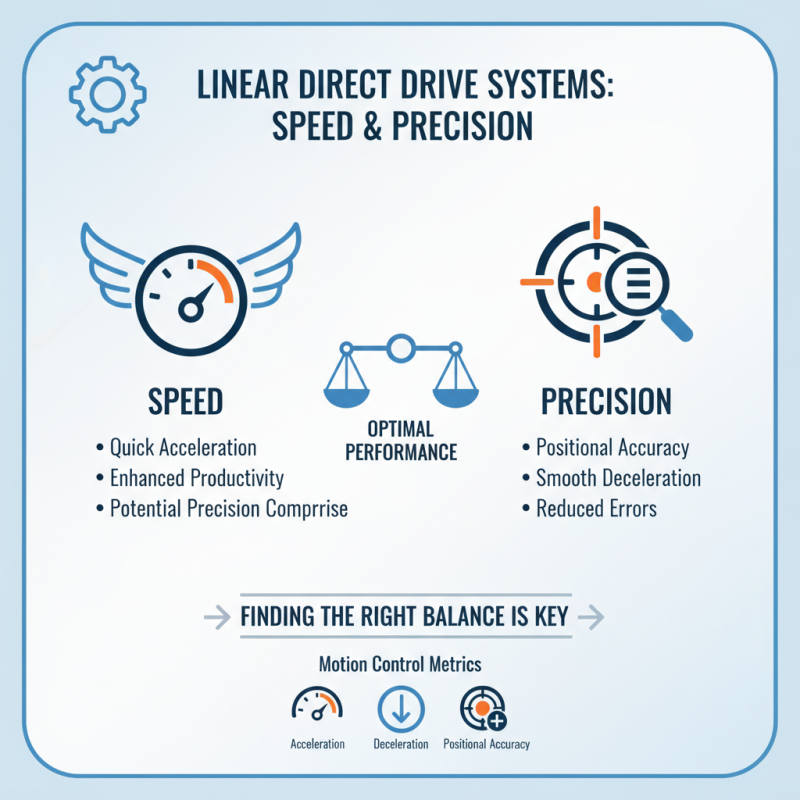

When selecting a linear direct drive system, speed and precision are crucial. These factors determine the performance in various applications. Motion control metrics include acceleration, deceleration, and positional accuracy. A drive that offers quick acceleration can enhance productivity. However, too much speed might compromise precision. Finding the right balance is key.

Understanding your needs is vital. If your project requires high-speed operations, focus on drives that excel in rapid response. Conversely, applications demanding intricate detail may prefer slower, more precise options. Evaluate how each motion control metric impacts your output. You might discover unexpected trade-offs in performance and reliability.

Testing different systems can yield insights. Hands-on experience helps clarify your specific requirements. Sometimes, results can be disappointing, prompting a reevaluation of your choices. Conduction thorough assessments early on can save time later. Balancing speed and precision is an ongoing challenge that requires thoughtful consideration.

When selecting a linear direct drive, cost and performance are often at odds. Financial factors play a crucial role in ensuring you get the best system for your application. According to a recent industry report, nearly 40% of companies consider total ownership cost as their primary selection criterion. This includes initial purchase price, maintenance, and energy efficiency. A system that seems affordable upfront may lead to higher costs over time.

Performance metrics, such as speed and precision, must be weighed against your budget. For example, a high-performance drive with an excellent torque rating may have a steep price tag, potentially doubling your investment. However, it can result in significant productivity gains. The data indicates that investing 20% more in a high-end model can lead to a 30% increase in output. This trade-off often requires careful consideration and reflections on your long-term goals.

It's also essential to factor in the hidden costs that arise from poor performance. A cheaper option could fail to meet required precision, leading to wasted materials and time. In fact, studies show that up to 25% of manufacturing expenses stem from inefficiencies in machinery. Thus, choosing based solely on price can be misleading. By thoughtfully analyzing cost versus performance, you can find a balance that fits your unique operational needs.

| Parameter | Value | Cost ($) | Performance Rating (1-10) |

|---|---|---|---|

| Max Load Capacity | 200 kg | 1500 | 8 |

| Max Speed | 1 m/s | 1200 | 7 |

| Precision | 0.01 mm | 1800 | 9 |

| Power Consumption | 350 W | 1100 | 6 |

| Maintenance Interval | 1000 hours | 900 | 8 |

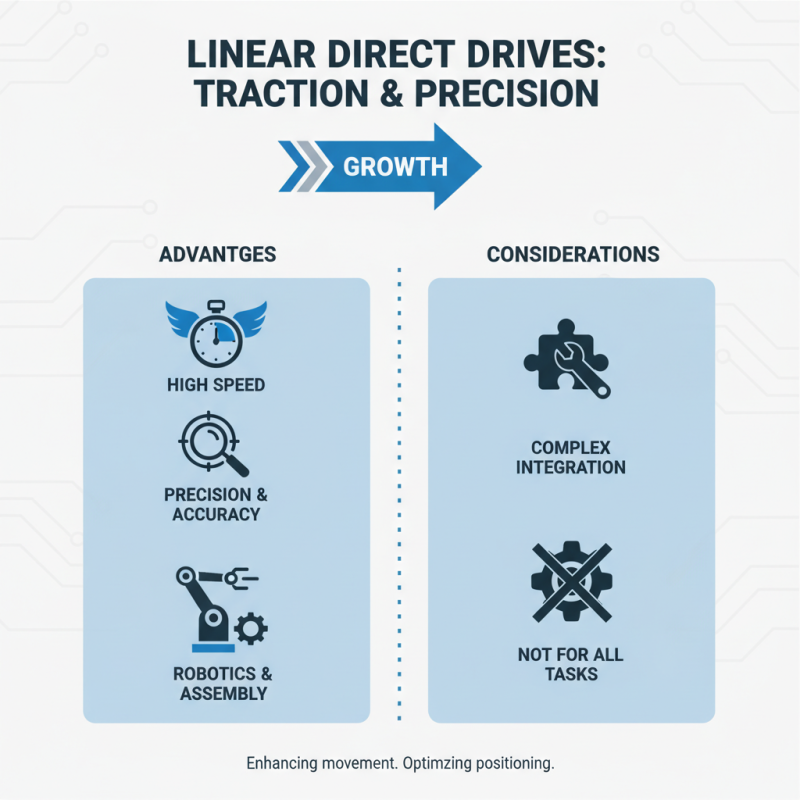

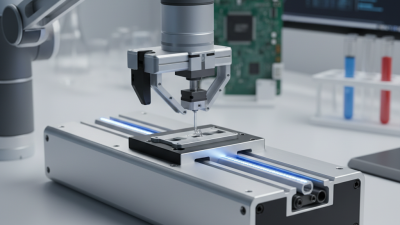

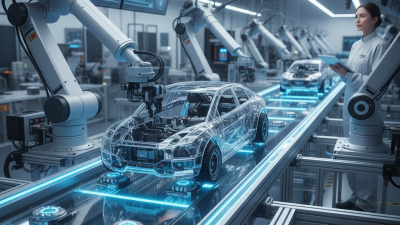

Linear direct drives are gaining traction across various industries. They excel in applications requiring high precision and speed. For instance, in robotics, these drives enhance movement accuracy. They facilitate quick positioning, which is crucial in assembly lines. However, they may not be suitable for all tasks. The complexity of integration can be a hurdle.

In manufacturing, linear direct drives optimize processes. They are ideal for CNC machines, improving cutting speeds. They also reduce mechanical wear in comparison to traditional systems. Still, the initial setup and cost could be barriers for some businesses. Understanding the specific needs of each application is vital.

Medical equipment also benefits from these drives. They provide reliable motion control in devices like MRI machines. Precision is critical in such applications, but noise can be an issue. Finding the right balance between performance and environment can be challenging. Companies must evaluate their requirements thoroughly to make informed choices.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.