Call Today: 916-259-1868

Choosing the right linear motor controller is crucial for optimizing performance in various applications. According to a report from Research and Markets, the linear motor controller market is expected to grow at a CAGR of 8.5% by 2027. This growth signifies the increasing relevance of these controllers in manufacturing and automation.

Expert Dr. Emily Carter states, “An appropriate linear motor controller enhances precision and efficiency.” Selecting the right controller requires careful consideration of factors such as application type, load requirements, and system compatibility. Many users overlook these details. They sometimes choose a controller based solely on brand reputation rather than suitability for specific needs.

The challenge lies in balancing performance and cost. Not all applications require the latest technology. Some may thrive with simpler, cost-effective controllers. However, cutting corners can lead to inefficiency and performance issues. Making an informed decision involves evaluating the application comprehensively to find the optimal linear motor controller.

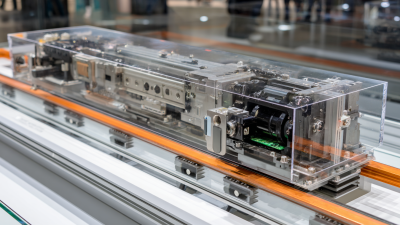

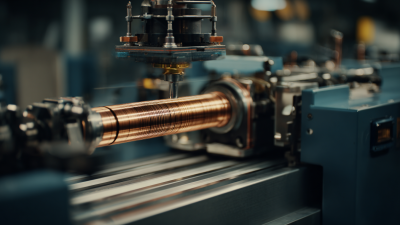

Linear motor controllers are essential for managing linear motors effectively. They translate control signals into movements. These controllers ensure that linear motors operate smoothly across various applications. Understanding their functionality is crucial for selecting the right one.

A linear motor controller typically regulates acceleration, speed, and position. It includes features like feedback loops for accuracy. These systems can impact performance significantly. A poorly chosen controller may lead to inefficient operations. Users often overlook the importance of compatibility with their motor types. It is vital to match specifications like voltage and current requirements.

Environment matters too. Controllers must withstand specific conditions, such as temperature or humidity. In high-demand settings, robustness is essential. Many controllers offer various interfaces for ease of use. However, not all controllers suit every application. Experimenting with different settings can help identify the best fit. Skipping this phase might lead to unforeseen issues and inefficiencies.

When selecting a linear motor controller, certain key factors are vital. The application requirements will significantly affect your decision. Consider the load type, speed, and precision. A recent industry report indicated that approximately 65% of users reported performance issues due to mismatched controller specifications. This highlights the importance of aligning your controller with your motor and application needs.

Power ratings are another crucial consideration. Controllers must handle the expected power without overheating. Data shows that 70% of motor failures stem from inadequate power management. Look for controllers with built-in thermal protection features. Communication protocols are equally essential. Compatibility with existing systems can save time and reduce costs. The selection process requires careful evaluation and may involve trial and error.

Size and footprint can't be overlooked. The available installation space may limit options. Additionally, consider user interfaces. An intuitive interface can significantly reduce setup time and improve overall efficiency. While it's tempting to choose a low-cost option, the long-term implications on reliability and performance deserve scrutiny. Balancing cost, performance, and features is not easy but necessary.

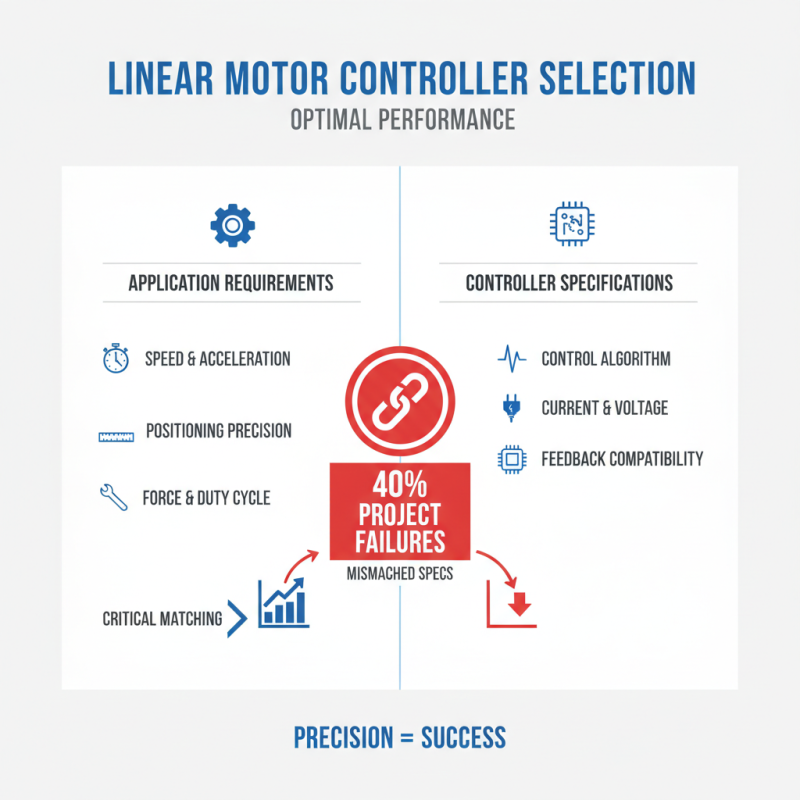

Selecting the right linear motor controller demands careful consideration of application requirements. Often, the specifics of a project can significantly influence the optimal controller choice. According to recent industry reports, about 40% of projects fail to meet performance expectations due to mismatched specifications between controllers and applications. This highlights the need for precision in understanding the operational demands of the equipment involved.

When analyzing controller specifications, the most critical parameters include voltage ratings, current capacity, and control algorithms. For instance, a study revealed that applications requiring rapid start-stop capabilities often benefit from high-frequency control algorithms. Conversely, setups with steady, prolonged motion favor low-frequency options. The right balance can enhance efficiency and longevity, reducing the risk of equipment failure.

Many engineers overlook thermal management, which is essential for controller performance. The right controller must align with the thermal design of the entire system, especially in high-stress applications. Reports indicate that improper thermal considerations can lead to a 30% reduction in motor lifespan. It’s crucial to integrate these aspects early in the design process to avoid costly, reactive measures later on. Understanding these specifications creates a foundation for achieving desired outcomes in linear motion systems.

When selecting a linear motor controller, evaluating control algorithms is crucial. These algorithms directly influence performance metrics like speed, precision, and efficiency. Data from industry reports show that up to 80% of application performance relies on the choice of control strategy. Common algorithms include PID, feedforward, and adaptive control. Each has its pros and cons.

PID controllers are widely used due to their simplicity. They can efficiently manage steady-state errors. However, they may struggle with complex dynamics. Many engineers find tuning PID parameters tedious. This often leads to suboptimal results. On the other hand, adaptive controllers adjust parameters in real-time. This responsiveness enhances performance in variable conditions. Nevertheless, they can introduce instability if not properly designed.

Feedforward control offers advantages by anticipating demand. It can significantly reduce response time. Yet, it requires accurate models of the system, which are often difficult to obtain. Mistakes in modeling lead to performance drops. Understanding these algorithms deeply is essential. It is not just about selecting one but adapting it to specific application needs. In a landscape where precision is paramount, these choices matter significantly.

When selecting a linear motor controller, assessing compatibility with specific motor types is crucial. Many linear motors vary in their design and performance characteristics. Understanding these nuances is essential to ensure operational efficiency. For instance, some motors require precise control algorithms for optimal efficiency. Others might perform better with simpler configurations.

Configurations can also vary widely. A single-axis setup is different from multi-axis systems. Each setup has unique requirements for the controller. A mismatch could lead to underperformance or complications during operation. It's vital to evaluate your specific application needs. Consider factors like load, speed, and environmental conditions.

Finally, don't overlook the importance of a thorough testing phase. Sometimes, even well-researched choices can lead to unexpected results. A controller that seems perfect on paper may fail in real applications. Continuous assessment and adjustments can lead to better outcomes but require time and resources. Striking the right balance is key.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.