Call Today: 916-259-1868

Choosing the right linear direct drive motor for your application is a critical decision that can greatly influence the efficiency, precision, and overall performance of your systems. With a wide array of options available in the market, understanding the fundamental characteristics and operational requirements of linear direct drive motors is essential for engineers and designers alike. These motors offer unique advantages, such as high torque at low speeds, minimal maintenance requirements, and the ability to deliver precise control, making them ideal for a variety of applications ranging from automation to robotics.

As you navigate the selection process, it is important to assess your specific operational needs, including load conditions, speed requirements, and environmental factors. Each application presents its own unique challenges, and the right choice of a linear direct drive motor can significantly enhance performance and reliability. By considering factors such as stroke length, thrust, dimensions, and the integration of control systems, you can better ensure that the selected motor aligns with your technical needs and operational objectives. This guide aims to provide essential insights into how to make an informed decision when choosing a linear direct drive motor, ultimately leading to more efficient and successful implementations in your projects.

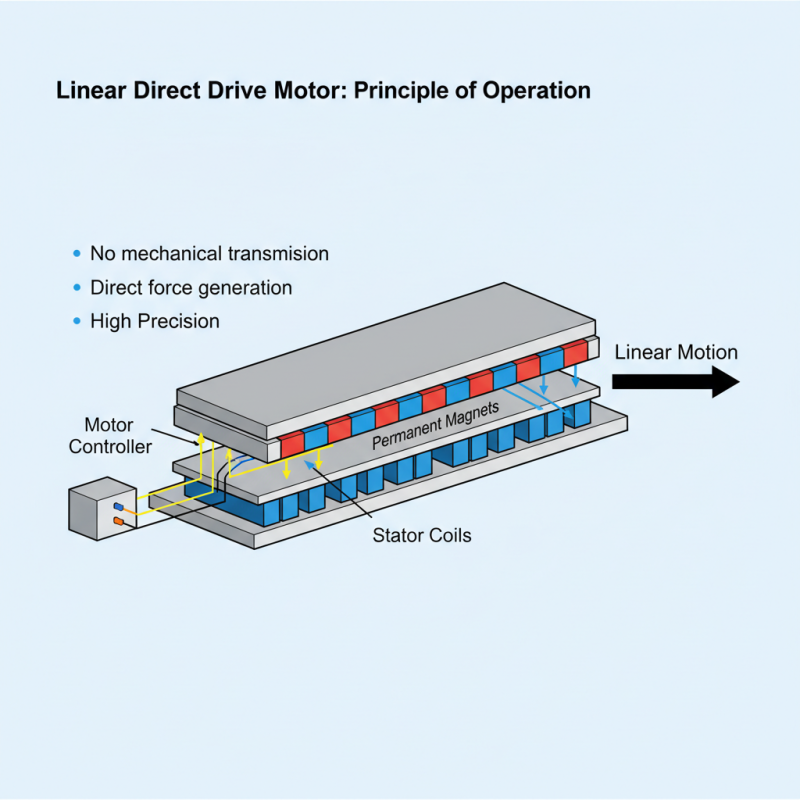

Linear direct drive motors have emerged as crucial components in various industries due to their ability to provide precise motion control and high-speed operation. Unlike traditional motors that rely on a mechanical transmission system, linear direct drive motors produce linear motion directly from electromagnetic forces, resulting in minimal friction and wear. This operational efficiency is particularly valuable in applications requiring high accuracy, such as semiconductor manufacturing and robotic assembly. According to the latest industry report by Research and Markets, the global direct drive motor market is projected to grow at a CAGR of approximately 7.5% from 2021 to 2026, driven by the increasing demand for automation and high-performance systems.

Understanding the fundamentals of linear direct drive motors is essential for selecting the proper motor for specific applications. Key performance metrics include thrust force, speed, and motion control resolution. Thrust force is generally proportional to the size of the motor and its coil design, impacting load capabilities in various applications. Speed is another critical factor that influences productivity, especially in fast-paced environments. Furthermore, advancements in digital control systems have enhanced the ability to achieve precise motion profiles, making linear direct drive motors suitable for complex applications such as CNC machines and material handling systems. Industry reports indicate that applications in automation and robotics account for over 40% of the demand for linear direct drive motors, highlighting their significance in modern manufacturing processes.

When selecting a linear direct drive motor for your application, several key specifications must be taken into account to ensure optimal performance. First and foremost, you should evaluate the motor's force output. This specification is crucial as it determines the motor's ability to move loads efficiently. You'll need to match the required force with the weight and inertia of the objects the motor will be moving, as this directly impacts acceleration and overall system responsiveness.

Another important factor is the travel speed and stroke length. Different applications may require varying speeds and distances, so understanding your operational demands is essential. It's also vital to consider the motor's resolution and accuracy, as they influence the precision of movement. High-resolution motors are ideal for applications like robotics and CNC machines, where even minor inaccuracies can lead to significant operational issues. Additionally, attention must be paid to thermal characteristics, including how the motor dissipates heat during prolonged use, as overheating can affect performance and longevity. Balancing these specifications will help you select a linear direct drive motor that meets your application needs effectively.

When selecting a linear direct drive motor, understanding the specific load and speed requirements of your application is crucial. The load refers not only to the weight that the motor needs to move but also to the inertia associated with that load. A motor must be able to overcome static and dynamic forces, ensuring smooth operation without stalling. An accurate assessment of the load characteristics will help in determining the necessary torque ratings and motor capacity.

Speed requirements are equally important, as they dictate the responsiveness and overall performance of the system. Consider both the maximum speed needed for your application and the acceleration/deceleration rates that are required for efficient operation. The motor's ability to attain these speeds promptly can significantly influence productivity and precision. Additionally, understanding the operational cycle of the application—whether it requires constant speed, variable speed, or quick responsiveness to changes—will guide you in making the best motor choice suited to your needs. Evaluating these aspects meticulously will ensure optimal performance and reliability of your linear direct drive system.

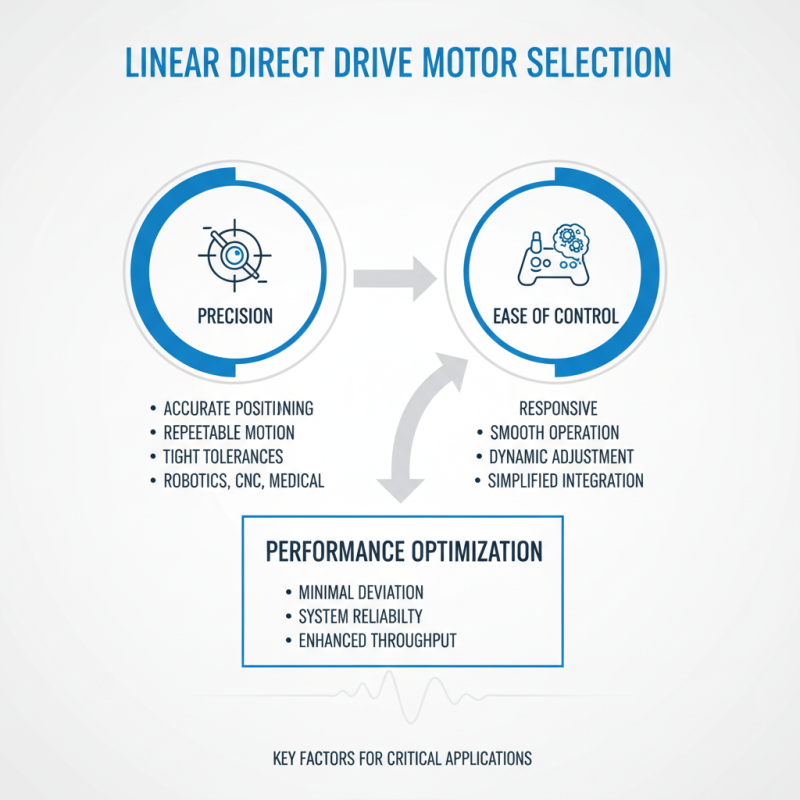

When selecting a linear direct drive motor for an application, precision and ease of control are paramount factors that significantly influence performance. Precision in a motor refers to its ability to deliver accurate positioning and repeatable motion. This characteristic is essential for applications that require tight tolerances and high levels of accuracy, such as robotics, CNC machining, and medical devices. The choice of motor must ensure that it can not only reach the desired position but also maintain it with minimal deviation, enhancing the overall reliability of the system.

Ease of control is equally crucial, as it affects how seamlessly the motor integrates with existing systems and the user experience. A motor that offers intuitive control options and compatibility with various control systems can streamline operations and reduce the learning curve for users. Advanced feedback mechanisms, such as encoders, can improve control accuracy, allowing for more nuanced adjustments and smoother operation. Ultimately, focusing on these two aspects—precision and ease of control—can help ensure that the selected motor aligns with the specific demands of the application, leading to optimized performance and efficiency.

When considering the investment in a linear direct drive motor, it's essential to conduct a thorough cost-benefit analysis to ensure that you are making a financially sound decision. While the initial purchase price may seem high, evaluating the long-term benefits can reveal substantial savings. A direct drive motor often results in reduced operational costs due to increased efficiency, lower maintenance needs, and a longer lifespan compared to traditional motor systems.

Tips for assessing the cost benefits include calculating the total cost of ownership over the motor's projected lifespan, including energy consumption and maintenance expenses. Moreover, consider the specific application requirements—motors designed for high precision and speed may provide a higher return on investment due to enhanced performance.

Additionally, explore potential productivity gains. A well-chosen motor can improve throughput and reduce cycle times, directly impacting profitability. Analyzing how the motor's performance aligns with your operational goals is crucial, as the right investment can lead to significant improvements in overall efficiency.

| Motor Type | Max Thrust (N) | Actuation Speed (mm/s) | Efficiency (%) | Cost ($) | Maintenance Frequency (months) |

|---|---|---|---|---|---|

| Type A | 300 | 200 | 85 | 1500 | 6 |

| Type B | 400 | 180 | 90 | 2500 | 12 |

| Type C | 250 | 220 | 80 | 1200 | 8 |

| Type D | 350 | 160 | 88 | 2100 | 10 |

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.