Call Today: 916-259-1868

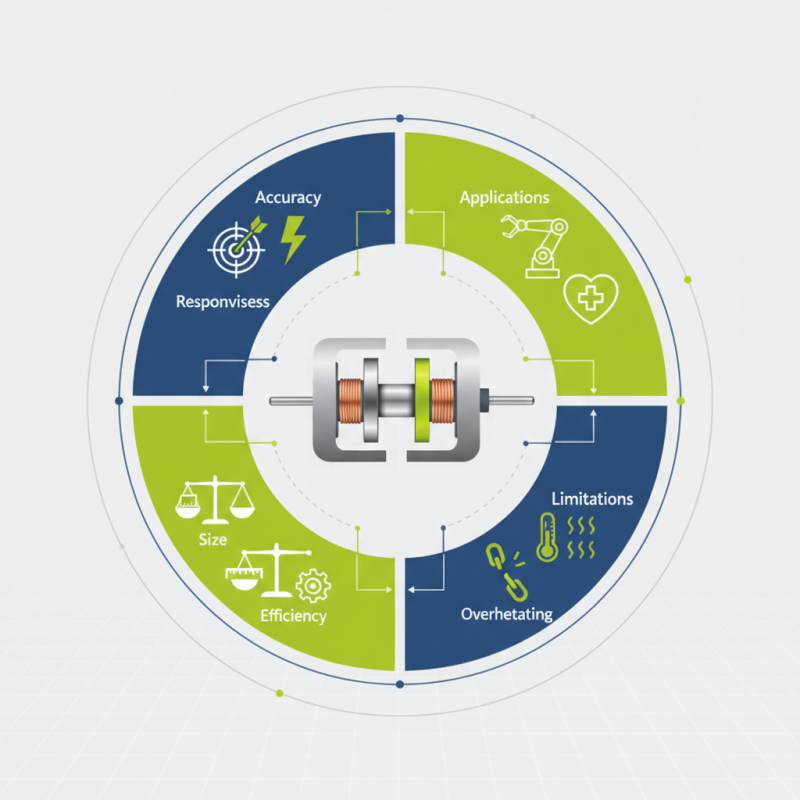

In the field of automation and precision control, the "moving coil actuator" stands out as a crucial component. Dr. Emily Carter, an expert in mechatronics, emphasizes its significance by stating, "Moving coil actuators deliver unmatched accuracy and responsiveness." This statement underlines the actuator's role in various applications, from robotics to medical devices.

The design of a moving coil actuator enables quick and precise movements. It utilizes electromagnetic principles, providing excellent control over positioning. When choosing an actuator, factors like size, weight, and performance efficiency must be considered. Users need to balance these parameters to meet their specific requirements effectively.

However, despite their advantages, moving coil actuators may not suit every application. Limitations in force output and potential overheating issues can arise. Decision-makers must carefully evaluate these aspects before implementation. Ultimately, exploring the benefits and drawbacks leads to more informed choices in automation technology.

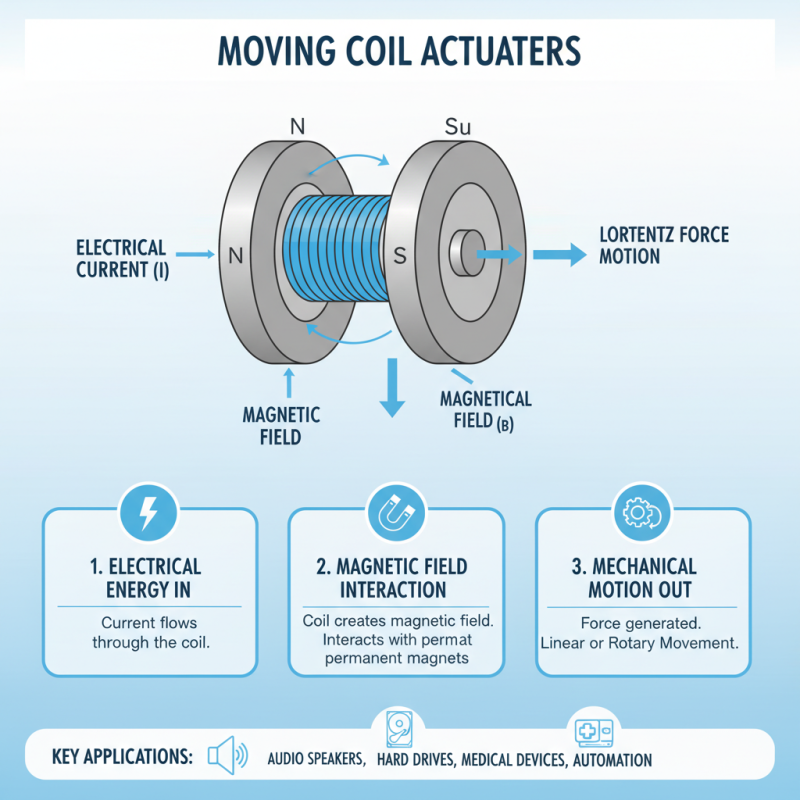

Moving coil actuators are a fascinating subject in the realm of electromechanical systems. They convert electrical energy into mechanical motion. This straightforward mechanism is influenced by magnetic fields. When current flows through the coil, it creates a magnetic field. This interaction produces movement, making them crucial in various applications.

These actuators are known for their simplicity and efficiency. They have relatively few moving parts compared to other systems. This design reduces wear and tear, leading to increased reliability. However, the simplicity can be a double-edged sword. Their performance may not meet high-demand scenarios, particularly in extreme conditions. Understanding their limitations is necessary before implementation.

In practical applications, moving coil actuators are prevalent in audio equipment and robotics. They provide precise control over small movements. Yet, their power limitations can hinder performance in larger systems. As engineers, we must evaluate the need for power versus precision. This balance is critical in achieving desired outcomes. A deeper understanding can lead to more informed choices in actuator selection.

Moving coil actuators stand out for several key reasons. They offer precise control, making them ideal for applications requiring accuracy. For example, in robotics, a moving coil actuator allows for smooth and accurate movement of arms or joints. This precision can enhance functionality and user experience.

Another advantage lies in their compact design. These actuators are small yet powerful. They deliver high performance without occupying much space. In situations where size matters, moving coil actuators provide a strong solution. Their lightweight nature further contributes to ease of integration into various systems.

However, challenges exist. Installation may require careful consideration. They can be sensitive to external forces, affecting reliability. Understanding these limitations is crucial. As technology evolves, it becomes vital to reassess the effectiveness and suitability of moving coil actuators for specific needs. Keeping up with new developments can mitigate potential drawbacks.

Moving coil actuators have become essential in various industries. They are commonly found in robotics, automotive systems, and medical devices. These actuators deliver high precision and responsiveness, making them ideal for tasks that require quick adjustments. In robotics, they enable smooth movements and accurate control, from robotic arms to automated guided vehicles.

In the automotive sector, moving coil actuators play a crucial role. They are used in electric power steering and adjustable seats. Their ability to respond instantly to changes makes driving experiences smoother and more enjoyable. In medical applications, these actuators power surgical instruments, enhancing precision during operations.

Despite their benefits, moving coil actuators can have drawbacks. For instance, they may struggle under extreme temperatures. Also, their mechanical components can wear down over time. Users must consider these factors when integrating them into systems. Balancing the advantages and limitations is key for successful applications.

| Application | Industry | Key Features | Typical Use Case |

|---|---|---|---|

| Robotic Actuators | Manufacturing | High precision, Compact design | Pick and place tasks |

| Medical Devices | Healthcare | Low noise, High reliability | Surgical tools positioning |

| Consumer Electronics | Electronics | Reactive, Fast response | Camera autofocus systems |

| Musical Instruments | Entertainment | Compact, Low power consumption | Electronic keyboards |

| Aerospace Applications | Aerospace | High durability, Lightweight | Control surfaces and actuators |

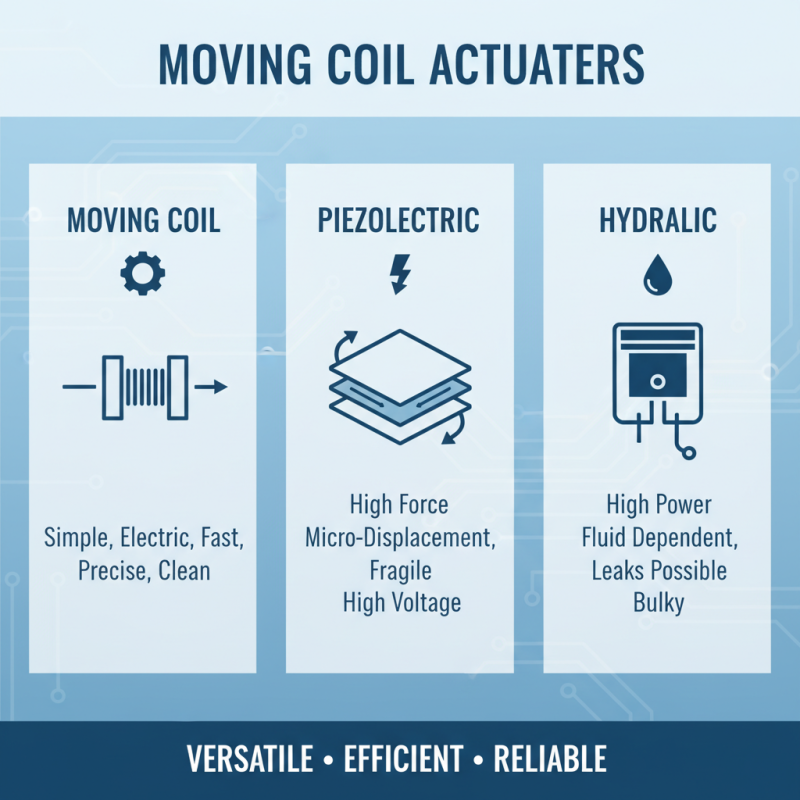

Moving coil actuators are a popular choice for various applications. Their simplicity and effectiveness make them stand out. When comparing them to other actuators, such as piezoelectric and hydraulic types, the differences become clear.

Moving coil actuators are known for their quick response and high precision. They convert electrical energy directly into motion. This direct conversion allows for smoother operation in devices like audio speakers and robotics. On the other hand, piezoelectric actuators offer high precision but can struggle with larger movements. Hydraulic actuators, while powerful, often require more space and maintenance. Their complexity might not be ideal for smaller applications.

Despite their advantages, moving coil actuators have limitations. They might not generate enough force for heavy-duty tasks. Additionally, their performance can degrade over time due to wear and tear. A careful assessment of your application needs is crucial. It's essential to consider both strengths and weaknesses when choosing an actuator.

When evaluating a moving coil actuator, several factors demand careful consideration. The actuator's force output is crucial. Typical force variability ranges from 1 to 10 Newtons for small applications. This level of precision is often necessary in robotics and precise control systems. Inadequate force may lead to equipment malfunction or inefficient operations.

Another key aspect is the actuator’s response time. Many applications require rapid movement. The ideal response time can be less than 10 milliseconds for high-performance needs. However, some devices may experience delays, impacting the overall system performance. Understanding these metrics is critical for successful implementation.

Thermal management is also important. Moving coil actuators can generate heat during operation. Proper cooling mechanisms must be in place. Failure to address thermal issues can lead to reduced lifespan or malfunction. Regular assessment of cooling needs can be beneficial. In some cases, users find an actuator's performance declines due to overlooked thermal factors. Thus, ongoing evaluation is pivotal for maintaining efficiency and reliability.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.