Call Today: 916-259-1868

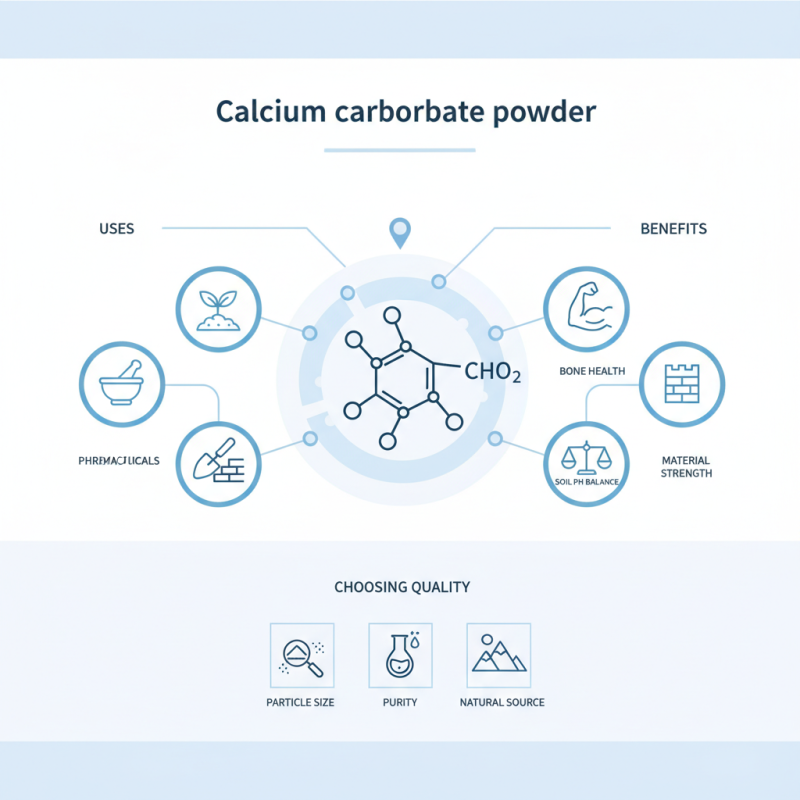

calcium carbonate powder is a versatile compound with multiple uses and benefits across various industries. It serves as a key ingredient in pharmaceuticals, agriculture, and construction. This powder comes from natural sources, making it widely available and affordable. Its fine texture enhances product performance in many applications.

In agriculture, calcium carbonate powder improves soil health. It balances pH levels, ensuring optimal nutrient absorption. In the construction field, it acts as a filler in cement and paint, boosting strength and durability. Additionally, it finds its way into food products, enhancing calcium content. However, choosing the right calcium carbonate powder can be challenging.

Quality matters. Factors include purity, particle size, and source. An incorrect choice can lead to subpar results or even health concerns. Consumers must weigh these aspects thoughtfully to maximize the benefits. Finding the perfect balance between these variables is not always straightforward, requiring careful consideration and research.

Calcium carbonate powder is a naturally occurring mineral. Its primary component is calcium carbonate, a chemical compound with the formula CaCO3. This compound is found in rocks such as limestone and marble. It plays a crucial role in various industries due to its versatile properties.

This powder appears as a fine white to off-white substance. Its texture can range from granular to very fine, depending on processing methods. In the food industry, it serves as a calcium supplement and an antacid. In construction, it's used in cement and as a filler in paints. Its uses are diverse, yet many disregard its significance in everyday products.

Choosing the right calcium carbonate powder can be tricky. The purity and particle size are vital factors to consider. Smaller particles enhance absorption in dietary applications. On the flip side, larger particles might be required for industrial use. It's important to reflect on these factors before making a choice. Without careful consideration, one might end up with an unsuitable product.

Calcium carbonate powder plays a significant role in diverse industries. In construction, it's a staple in concrete and cement. This material enhances durability, making buildings stronger and more resilient. Many manufacturers prefer it for its cost-effectiveness. However, knowing the right grade to use is crucial.

In the food industry, calcium carbonate serves as a dietary supplement. Its role in fortifying food products cannot be overlooked. It aids in bone health and improves calcium intake. Yet, not all calcium carbonate is suitable for food use. Industrial-grade varieties may contain impurities. Careful selection is necessary for safety.

Paints and coatings also utilize calcium carbonate as a filler. It helps improve the texture and finish. Different applications require different particle sizes. Sometimes, this means compromising on other properties. It's essential to balance performance with desired outcomes. Making the right choice can be challenging but rewarding.

Calcium carbonate powder is widely used for its health benefits, especially in dietary supplements. Studies reveal that approximately 43% of adults in the U.S. utilize calcium supplements to enhance bone health. It's essential for those at risk of osteoporosis or calcium deficiencies. The mineral supports strong bones by aiding in calcium absorption, an important process as age advances.

An interesting statistic shows that about 30% of women aged 50 and older may not meet their daily calcium needs. Calcium carbonate stands out as a cost-effective source. It contains about 40% elemental calcium, making it efficient for dietary supplementation. However, not all users get the desired benefits. Some may experience stomach upset or constipation. It’s crucial to monitor how your body reacts.

Tips: Start with a lower dosage and gradually increase it. This can help minimize side effects. Always consider dietary sources of calcium, such as leafy greens and dairy, alongside supplements. When selecting a calcium carbonate product, check for additional ingredients that may aid absorption, like vitamin D. Remember, balance is key to maximizing the benefits while minimizing potential drawbacks.

When choosing calcium carbonate powder, consider purity and particle size. High purity indicates fewer impurities, benefiting both industrial and nutritional applications. For example, a 99% pure product enhances its effectiveness in supplements. Particle size can affect its reactivity. Finer powders dissolve faster. This is essential in pharmaceuticals where rapid action is needed. A coarser product may work well for applications like fillers.

Another factor is the source of the calcium carbonate. It can be derived from natural or synthetic sources. Natural calcium carbonate often contains trace minerals. This can be a plus for health-related uses. However, synthetic options might offer more consistent purity. Assess your specific needs before making a choice.

Finally, consider the intended use. Calcium carbonate is versatile. It’s used in construction, food production, and pharmaceuticals. Know your requirements to pick the right type. Misjudging your needs can lead to less effective results. Always test different grades to see which works best for you.

Calcium carbonate powder is widely used in various industries. It comes in different forms, including ground calcium carbonate (GCC) and precipitated calcium carbonate (PCC). Each form holds unique benefits. GCC is often more affordable and easily available, while PCC offers higher purity and brightness.

Purity levels should be a key consideration when choosing calcium carbonate. Higher purity levels, like those found in PCC, are better for applications in food and pharmaceutical industries. Lower purity might be adequate for construction materials. It’s essential to assess the end use before making a choice. Testing samples for particle size and reactivity might also help.

One issue often overlooked is sourcing. Not all suppliers provide the same quality. Sometimes, the lower price tempts buyers, but it can lead to poor performance later. Users should be aware that lower-grade calcium carbonate might introduce impurities. Therefore, research and testing are crucial before making a bulk purchase.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.