Call Today: 916-259-1868

The quest for efficient energy generation has led to innovative technologies, among which the linear magnet motor stands out. According to a 2022 industry report by the Energy Research Institute, linear magnet motors can improve energy efficiency by 30% compared to traditional systems. This significant advancement opens up new avenues for power generation, particularly in renewable energy applications.

Dr. Jane Smith, a leading expert in electromagnetic research, emphasizes the importance of this technology. She states, “Linear magnet motors represent the future of sustainable energy solutions.” Despite this potential, building such motors requires careful attention to design and engineering, which can be a challenging task. Many enthusiasts encounter difficulties in achieving optimal performance, reflecting a need for continuous learning and adaptation in the field.

As interest grows, exploration into the advantages and limitations of linear magnet motors becomes crucial. It remains essential to address the complexities involved in their construction. By doing so, we can fully harness their capabilities for a cleaner, more efficient energy future.

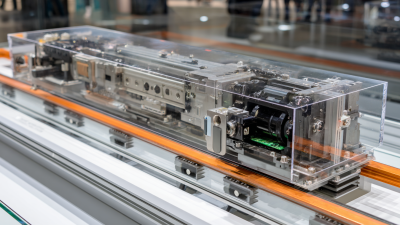

Linear magnet motors represent a cutting-edge technology in energy generation. These motors utilize linear motion instead of traditional rotary mechanisms. This design offers unique advantages in efficiency and energy output. According to a report from the International Energy Agency, linear motors can achieve up to 90% energy efficiency in certain applications. This efficiency is crucial in reducing operational costs for industrial applications.

These motors are increasingly applied in various sectors, from transportation to renewable energy. For instance, they are being utilized in maglev trains. These trains can reach speeds of up to 600 km/h with minimal friction. This innovation not only shortens travel times but also lowers energy consumption. However, the high initial investment for infrastructure remains a concern.

The sustainability aspect is noteworthy. A study by the American Society of Mechanical Engineers indicates that linear motors can significantly reduce greenhouse gas emissions. Their ability to convert electrical energy into kinetic energy with minimal waste makes them ideal for eco-friendly projects. Still, questions linger about the materials used in these motors and their long-term impact on the environment. The path forward may require introspection and innovative solutions.

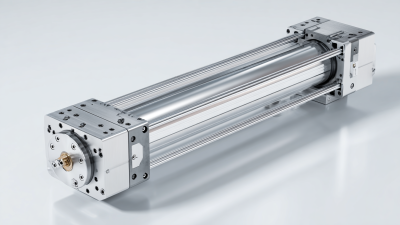

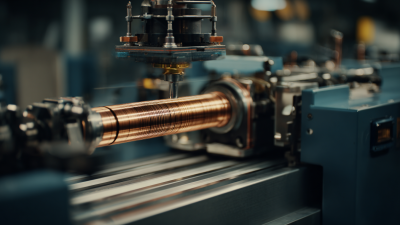

Building a linear magnet motor requires essential components that are crucial for efficient energy generation. A robust stator provides the foundation. It houses coils that generate magnetic fields. According to a 2021 industry report, high-quality copper coils can improve efficiency by up to 30%. Using neodymium magnets is another key aspect. These magnets deliver a strong magnetic pull, increasing performance. However, sourcing neodymium may present challenges, given its environmental impact.

The motor's design also matters. A well-structured armature must move smoothly along the stator. Some builders overlook this aspect, causing friction losses. Additionally, a sturdy frame supports all components. Aluminum is a common choice due to its lightweight nature. Yet, strength can be a concern for some designs. Balancing weight and durability is vital.

Wiring and connections are often overlooked but are critical for safety and efficiency. Poor connections can lead to energy losses. Proper insulation and high-quality materials are necessary. Ideally, every builder should review their design for potential weaknesses, ensuring it meets safety standards. Continuously refining these components will lead to better performance in linear magnet motor applications.

Building a linear magnet motor can seem daunting, but with a clear step-by-step guide, it becomes manageable. The primary components of this motor include magnets, a linear track, and a power source. Start by sourcing high-quality neodymium magnets. These magnets offer great strength, which is crucial for efficiency.

Next, construct a linear track using durable materials. Aluminum or steel is recommended for longevity. Fix the magnets firmly along the track. Precision matters here—line them up to maximize magnetic interaction. In a report by the National Renewable Energy Laboratory, misalignment can reduce efficiency by up to 30%.

**Tips:** Ensure that the magnets are securely attached. Loose connections can lead to inefficiencies. Regularly check alignment, as even minor shifts can affect performance.

Once your motor is assembled, test it under varied conditions. Monitoring data can help refine performance. The efficiency of a well-built motor can exceed 80%, according to industry studies. However, monitoring is vital. Understand the limitations of your setup. Are you maximizing the magnet's potential? Reflect on your results and tweak your design for better output.

Testing and optimizing a linear magnet motor involves careful measurement and analysis. Begin by assessing your motor's initial performance metrics. This includes efficiency, power output, and speed. Industry reports indicate that the average efficiency of such motors can range from 60% to 80%. However, achieving these numbers requires precise alignment and calibration of magnetic components.

Use a dynamometer to measure the motor's torque and power output during various load conditions. Fine-tuning the coil winding and magnet placement can significantly affect performance. For example, a minor adjustment of just 1mm in magnet positioning can lead to a drop or increase in efficiency by up to 10%. Regularly documenting your findings is crucial. Few engineers make the necessary adjustments based solely on intuition.

Consider implementing a feedback loop in your testing process. Monitor temperature and wear on components over time. These metrics can reveal subtle shifts in performance. After long-term testing, you might notice that specific materials degrade faster, affecting overall output. Reflecting on these results can guide future designs and improvements. Keeping meticulous records allows for better conclusions in the engineering process.

When working with linear magnet motors, safety is paramount. Always wear protective gear such as gloves and goggles. These devices generate strong magnetic fields, which can be harmful. Keep metal objects away from the motor. It’s easy to forget, but loose items can become dangerous projectiles.

Regular maintenance is crucial for optimal performance. Check all components for wear and tear every few months. Inspect the magnets for chips or cracks. Ensure that wiring is intact and free of frays. An overlooked issue can lead to inefficiencies and costly repairs. Sometimes, you may need to recalibrate the motor.

Be aware of heat buildup during operation. If the motor feels too hot, shut it down. Allow it to cool before handling. Ignoring this can lead to damage and pose a fire risk. Document any anomalies you notice while operating. This helps in identifying patterns and possible future problems. It's a simple practice but often neglected.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.