Call Today: 916-259-1868

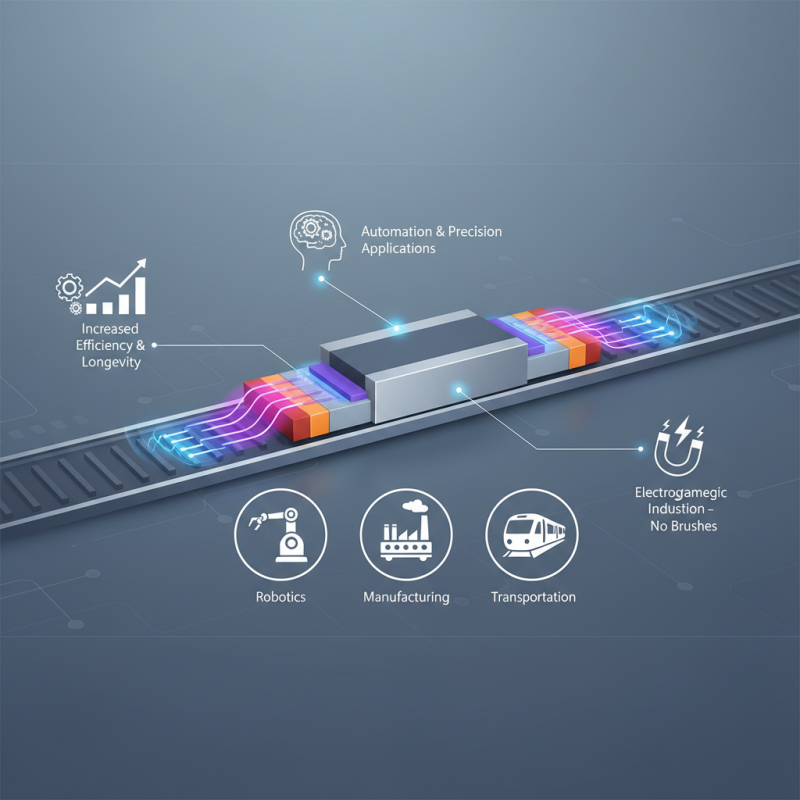

The brushless linear motor represents a revolutionary advancement in motion control technology, offering numerous advantages over traditional motors. According to Dr. Emily Carter, a leading expert in the field of linear motor technology, "Brushless linear motors are transforming the way we approach automation and precision applications." This technology operates on principles of electromagnetic induction, generating linear force without the need for mechanical commutation.

By eliminating brushes, these motors reduce friction and wear, resulting in increased efficiency and longevity. This innovation has opened up new possibilities in various sectors, including robotics, manufacturing, and transportation. As industries continue to seek enhanced performance and reliability, understanding the intricacies of brushless linear motors becomes paramount. In this article, we will delve into the workings of brushless linear motors, their benefits, and their potential applications in the modern world.

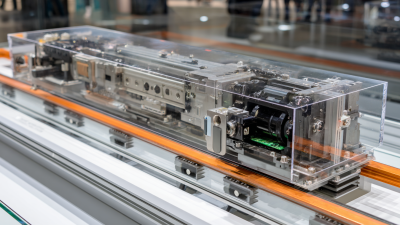

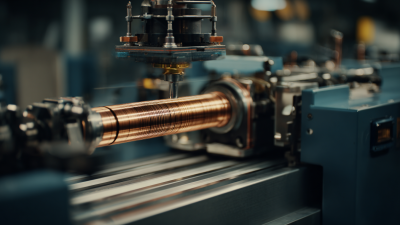

A brushless linear motor is a type of electric motor that produces linear motion instead of rotational motion, utilizing electromagnetic principles. Unlike traditional motors, which have brushes that make physical contact with the commutator, brushless linear motors rely on magnetic fields generated by coils and permanent magnets. This design eliminates mechanical wear and enhances reliability, making them an ideal choice for high-precision applications.

One key feature of brushless linear motors is their efficiency. With fewer moving parts, they can operate smoothly and with minimal energy loss. Additionally, these motors provide precise control over speed and position, allowing for applications in robotics, automation, and CNC machinery. Their ability to deliver high force and acceleration also makes them suitable for dynamic applications, providing significant advantages over traditional linear motors.

Tips: When selecting a brushless linear motor, consider the application requirements such as load capacity, speed range, and precision. Ensure that the motor's specifications align with your project's demands to maximize performance and efficiency. Also, pay attention to factors such as environmental conditions and mounting configurations that may affect the motor's operation.

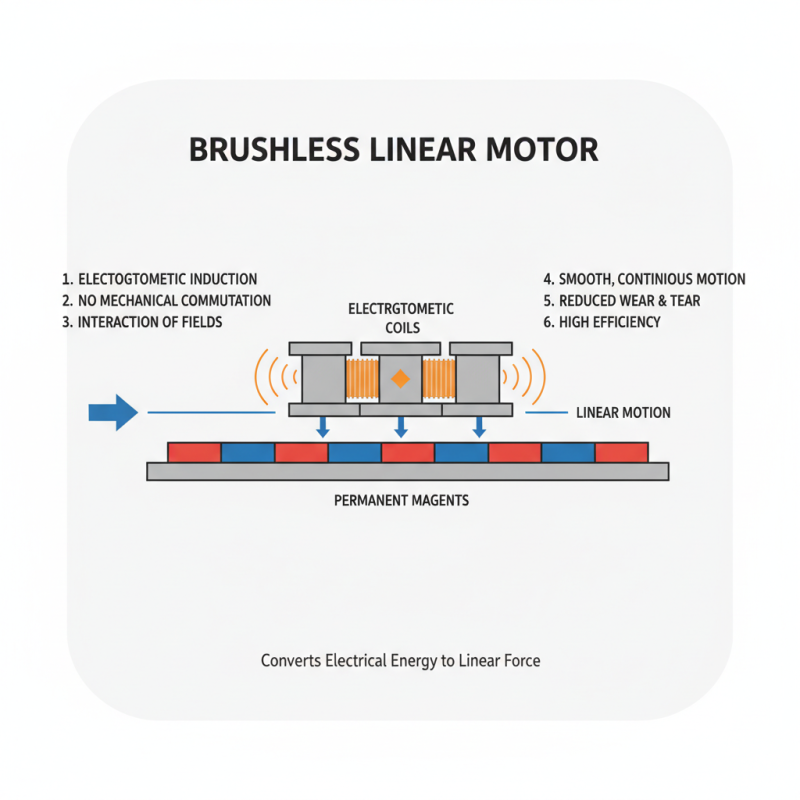

Brushless linear motors operate on the principles of electromagnetic induction, providing a reliable and efficient means of converting electrical energy into linear motion. Their design eliminates the need for mechanical commutation by using an array of permanent magnets and electromagnetic coils. In this setup, the interaction between the magnetic field produced by the coils and the fixed magnets generates linear force, allowing for smooth, continuous motion without the wear and tear associated with traditional brushed motors.

The mechanism begins when electric current flows through the coils, creating a magnetic field. This field interacts with the magnets positioned on the moving component, propelling it in a straight line. By controlling the current in the coils with precise timing, the motor achieves high-speed operation and accurate positioning. Additionally, the use of feedback systems enhances performance, as they continuously monitor the position of the moving parts, allowing for real-time adjustments to maintain optimal operation. This sophisticated interplay of magnetic forces ensures that brushless linear motors are not only efficient but also capable of providing high precision in applications where exact movement control is essential.

Brushless linear motors have gained significant attention in industrial applications due to their unique benefits. Unlike traditional motors, which rely on rotating components, brushless linear motors provide direct linear motion, resulting in higher efficiency and precision. This technology minimizes mechanical wear and tear, leading to extended service life and reduced maintenance costs.

As industries increasingly move towards automation and high-speed operations, the reliability and performance of brushless linear motors make them an ideal choice for various applications, from assembly lines to advanced robotics.

Tips for selecting the right brushless linear motor

Another advantage of brushless linear motors lies in their energy efficiency. They consume less power compared to traditional systems, which can translate into significant cost savings for businesses.

Moreover, their ability to operate quietly enhances workplace comfort, making them suitable for applications where noise reduction is critical. Investing in brushless linear motor technology can lead to improved productivity and a more sustainable operation over time.

Brushless linear motors (BLMs) represent a significant advancement over traditional rotary motors, particularly in terms of efficiency and performance metrics. Unlike conventional motors, which rely on mechanical components such as brushes and commutators that contribute to friction and wear, brushless linear motors employ magnetic fields to produce linear motion directly. This inherent design leads to increased efficiency, with studies indicating that BLMs can achieve up to 90% efficiency in specific applications, compared to 70-80% for traditional motors. The reduction in mechanical losses not only enhances energy savings but also extends the operational lifespan of BLMs due to their lower wear rates.

Performance metrics further highlight the advantages of brushless linear motors. With rapid acceleration and deceleration capabilities, these motors can achieve response times in the range of milliseconds, a significant improvement over the time delays often associated with traditional motor setups. In sectors such as automated manufacturing and robotics, the precision and speed of BLMs contribute to improved throughput rates, with performance benchmarks showing that they can operate at speeds exceeding 5 m/s while maintaining positional accuracy within micrometers. According to industry reports, this makes brushless linear motors particularly advantageous for applications requiring high-speed, high-precision movement, thereby revolutionizing how industries approach automation and mechanical design.

| Parameter | Brushless Linear Motor | Traditional Motor |

|---|---|---|

| Efficiency | > 90% | 70% - 85% |

| Maintenance | Low | High |

| Operational Noise | Low | Moderate to High |

| Speed | High | Moderate |

| Control Precision | High | Moderate |

| Initial Cost | High | Lower |

| Lifespan | Long | Short |

Brushless linear motors have emerged as transformative components across various industrial sectors, offering high efficiency and precise control. One of the primary applications is in automation within manufacturing environments, where these motors drive conveyors, assembly lines, and robotic arms. Their ability to provide instant torque and smooth motion enhances operational throughput, reducing cycle times and increasing overall productivity.

Another critical sector capitalizing on brushless linear motor technology is the medical field. These motors are commonly used in precision instruments such as MRI machines, surgical robots, and laboratory equipment, where accuracy and speed are paramount. The reliability and reduced maintenance needs of brushless linear motors make them particularly suitable for environments requiring stringent cleanliness and operational reliability.

Additionally, the packaging industry benefits significantly from these motors, as they facilitate fast and accurate movement for filling, sealing, and labeling processes. The adaptability of brushless linear motors allows them to accommodate various package sizes and materials, providing manufacturers with the flexibility needed in high-speed production lines. Overall, the integration of brushless linear motors in these key sectors demonstrates their essential role in modern industry, boosting efficiency and precision.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.