Call Today: 916-259-1868

In the rapidly evolving landscape of industrial applications, the direct drive torque motor stands out as a game-changer. Experts like Dr. Emily Carter, a leading authority in motion control technologies, state, “Direct drive torque motors provide unmatched precision and efficiency.” This insight encapsulates the pressing need for innovation in today's competitive market.

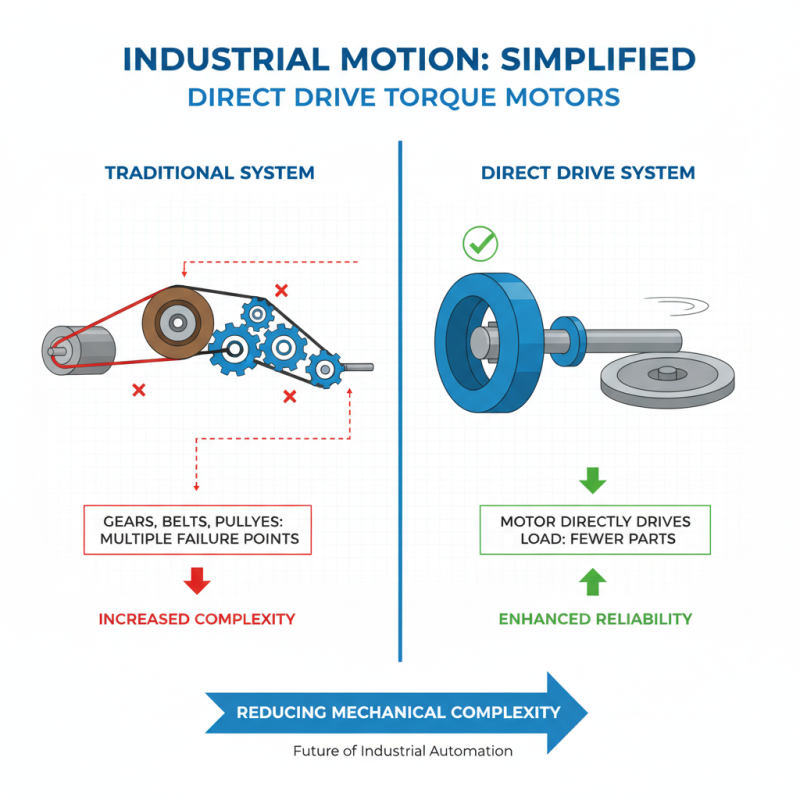

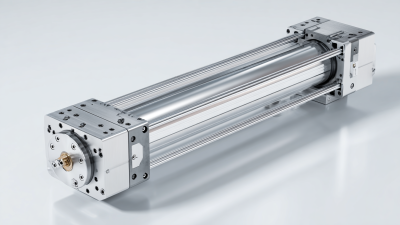

Direct drive torque motors eliminate the need for gears and belts. This leads to reduced wear and maintenance costs. Industries can achieve higher performance levels with fewer components. The benefits extend beyond mere efficiency. These motors enable better control and faster response times, which are crucial in various applications.

However, the transition to direct drive torque motors is not without challenges. Businesses must invest in new systems and retrain staff. This adjustment period can be daunting, yet the rewards are considerable. Embracing this technology may involve hurdles, but the potential for revolutionizing productivity makes it a worthy consideration for industrial players.

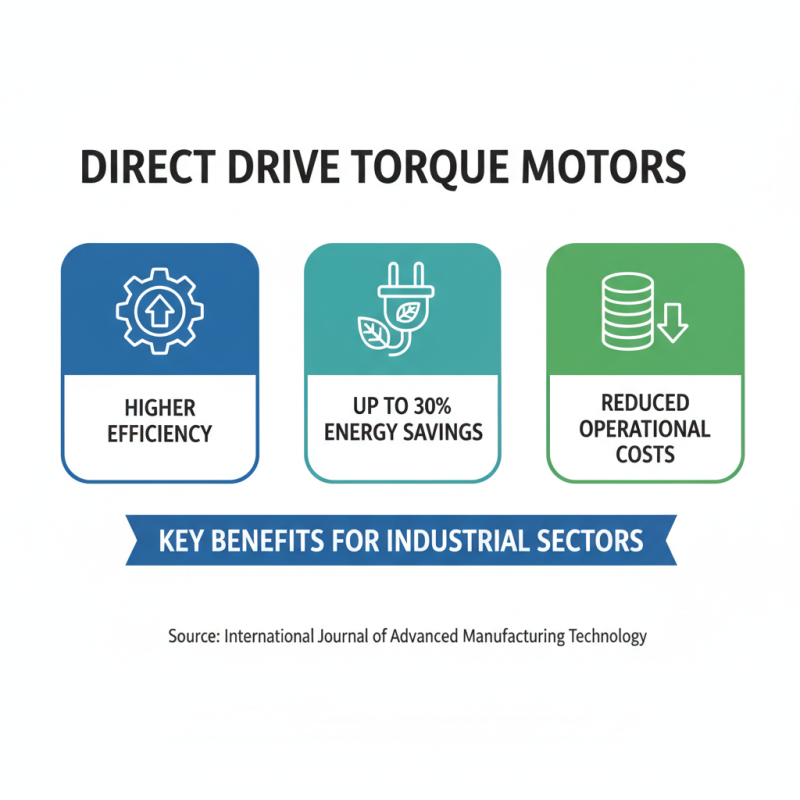

Direct drive torque motors have become increasingly popular in precision applications due to their unique advantages. These motors eliminate the need for gearboxes, which reduces mechanical complexity. This simplification often results in better efficiency. According to a report by the International Society of Automation, systems using direct drive motors can achieve energy savings of up to 30%. This reduction in energy consumption is crucial for environmentally conscious operations.

Precision is another major benefit of direct drive torque motors. They provide high torque at low speeds, making them ideal for applications requiring fine adjustments. For instance, in CNC machining, direct drive motors enable faster and more precise table movements. Data indicates that companies using these motors report up to 20% improvement in production cycle times. This can significantly enhance overall throughput.

Despite these benefits, some challenges remain. Implementation costs can be high, and not every application may require such precision. System integration can also pose difficulties. Therefore, it's important to evaluate whether a direct drive system is truly necessary. Some manufacturers may find that traditional options still meet their needs, especially in less demanding contexts. Balancing effectiveness and cost is vital in decision-making.

Direct drive torque motors are reshaping industrial applications by reducing mechanical complexity. Traditional systems often have multiple gears, belts, and pulleys. Each component adds potential points of failure. By using direct drive technology, the need for these parts is minimized. This simplification enhances overall system reliability.

Fewer mechanical components mean less maintenance. Maintenance downtime costs money and limits productivity. Fewer parts can lead to improved performance. This shift to direct drive systems can bring about more efficient operation. However, not all industries are ready to make this switch. Some may still rely on older systems due to habit or risk aversion.

**Tip:** Always evaluate the specific needs of your machinery. Understand how a direct drive system fits into your operations. It may not be a one-size-fits-all solution. **Tip:** Consider the long-term benefits versus the initial investment. Can you afford to make a change? Sometimes, hesitation can block progress. Reflecting on your equipment’s reliability can lead to better decisions.

Direct drive torque motors are changing the industrial landscape. They offer high efficiency that leads to significant energy savings. Reducing energy consumption is crucial in today’s operations. Unlike traditional motors, these systems eliminate gearboxes. This design reduces friction and mechanical losses. The direct connection to the load also enhances responsiveness.

Efficiency translates into cost savings. Companies see lower utility bills due to optimized energy use. For example, a plant running 24/7 can exhibit noticeable savings over time. It's a tangible benefit that can be measured and tracked. However, transitioning to this technology isn't always straightforward. Existing infrastructure may not easily accommodate new systems.

Tips for implementation:

Direct drive torque motors are revolutionizing industrial applications. They provide significant benefits in performance while reducing maintenance needs. Traditional motors often require complex gear systems. These systems can wear out over time, leading to costly repairs. In contrast, direct drive motors have fewer moving parts. This simplicity results in lower maintenance requirements and increased reliability.

One interesting detail is the efficiency of these motors. They can achieve higher torque with less energy input. This leads to cost savings in energy bills over time. However, some users report challenges in initial setup. Adjusting the parameters for optimal performance can take time. These motors also rely heavily on proper installation and alignment. Misalignment can lead to increased wear and potential failures.

Maintenance is simplified with direct drive systems. Routine checks are often reduced to basic visual inspections. Some operators find the lack of routine tasks refreshing. Still, there is a need for training to understand the technology better. New users may struggle with troubleshooting without extensive experience. Overall, while the benefits are clear, adapting to this technology requires careful thought.

| Benefit | Description | Impact on Operation |

|---|---|---|

| High Efficiency | Eliminates the need for gears, resulting in higher energy efficiency. | Reduced energy costs and increased productivity. |

| Compact Design | Smaller size compared to traditional motors allows for better space utilization. | Easier integration into tight spaces. |

| Low Maintenance | Fewer moving parts leads to reduced wear and tear. | Lower downtime and maintenance costs. |

| High Torque Density | Provides high torque outputs in a compact package. | Better acceleration and performance in applications. |

| Improved Precision | Offers precise control in motion applications. | Enhanced quality of manufactured products. |

| High Reliability | Robust construction ensures consistent performance over time. | Less operational risk and increased uptime. |

| Low Noise Operation | Operates quietly, minimizing noise pollution. | Better working environment for personnel. |

| Thermal Management | Designed to manage heat better than traditional motors. | Prolonged lifespan and stable operation. |

| Versatile Applications | Can be used in various industries from robotics to packaging. | Increases the flexibility of manufacturing setups. |

| Enhanced Control Capabilities | Advanced control options for improved operation. | Optimized production processes and efficiency. |

Direct drive torque motors are becoming increasingly popular across various industrial sectors. Their unique design eliminates the need for gears, providing higher efficiency. A report from the International Journal of Advanced Manufacturing Technology states that these motors can reduce energy consumption by up to 30%. This is a significant improvement for industries looking to cut operational costs.

In manufacturing, these motors excel in applications like robotics and CNC machines. Their precision is impressive, leading to higher product quality. Industries that need swift responses benefit greatly from this technology. According to a recent study by the Robotics Industry Association, companies using direct drive torque motors report up to a 25% increase in production rates. However, the initial investment can be a hurdle for small businesses.

The versatility of direct drive motors extends beyond manufacturing. In packaging, they improve reliability and speed without compromising safety. Yet, challenges remain. Integration with existing systems can be complicated. Not every operation may benefit from switching to direct drive. Ongoing assessments are crucial. Making informed decisions can lead to better outcomes in industrial efficiency.

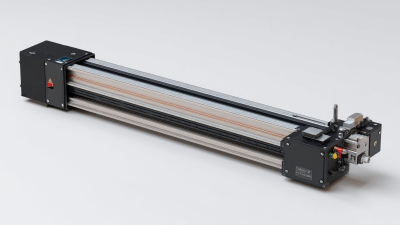

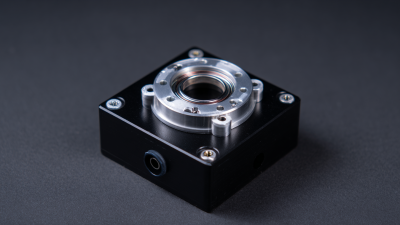

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.