Call Today: 916-259-1868

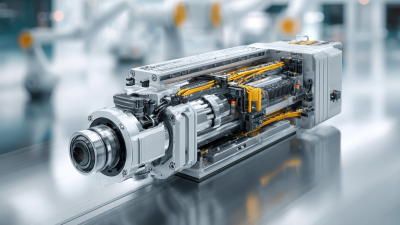

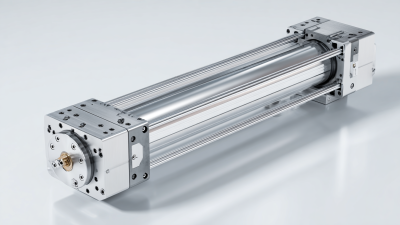

The linear direct drive motor has emerged as a revolutionary technology in various modern applications, offering significant advantages over traditional mechanical systems. In an era where precision, speed, and efficiency are paramount, industries ranging from robotics to manufacturing are increasingly turning to these innovative motors.

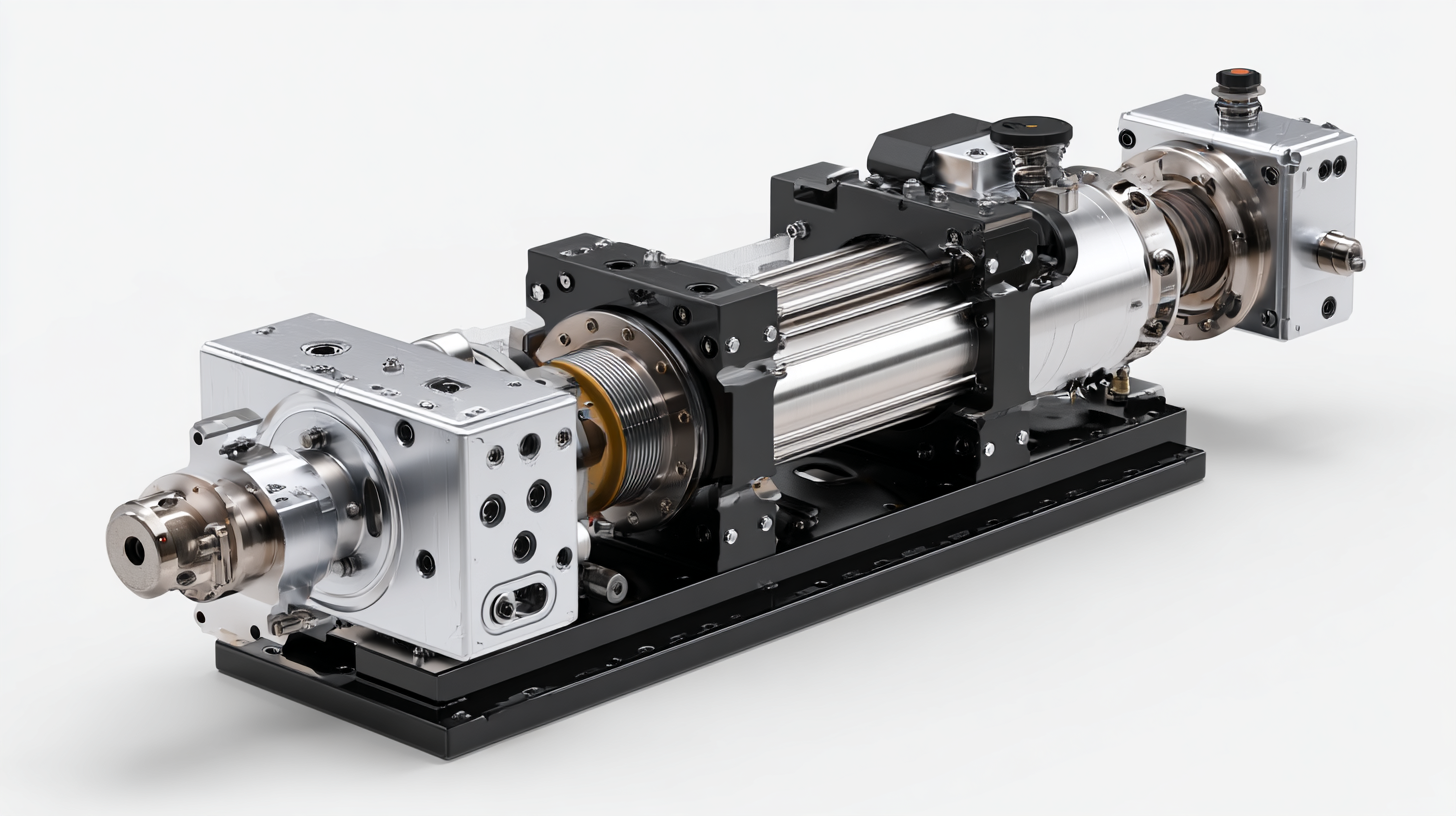

Unlike their rotary counterparts, linear direct drive motors provide seamless linear motion without the need for gears, belts, or other mechanical components that can introduce friction and reduce performance. This technology not only enhances the accuracy of movements but also minimizes maintenance costs and improves energy efficiency.

As we delve deeper into understanding the applications and benefits of linear direct drive motors, we uncover their pivotal role in advancing automation, enhancing machinery performance, and driving the future of various technological innovations.

Linear Direct Drive Motors (LDDMs) are transforming the landscape of precision engineering by delivering unparalleled accuracy and responsiveness. Unlike traditional rotary motors, LDDMs convert electrical energy directly into linear motion, eliminating the need for mechanical gears and reducing friction. This innovation results in smoother operation, significantly increasing the efficiency of machinery in applications ranging from semiconductor manufacturing to robotics. According to a recent report by MarketsandMarkets, the global linear motor market is expected to grow from USD 3.49 billion in 2022 to USD 4.84 billion by 2027, driven largely by advances in automation and precision engineering.

The advantages of LDDMs extend beyond just enhanced performance. Their design inherently provides excellent control over position, speed, and acceleration, making them ideal for applications requiring extreme precision. For instance, in the field of CNC machining, LDDMs contribute to a reduction in machining errors by 30%, as highlighted in a study by the International Journal of Advanced Manufacturing Technology. Additionally, the compact size and lightweight nature of LDDMs enable more flexible equipment design, allowing engineers to create innovative and space-efficient systems that can operate in confined environments. The integration of LDDMs thus represents a significant leap forward in the pursuit of accuracy and efficiency in modern technology.

| Application Area | Benefit | Precision Level | Speed (m/s) | Energy Efficiency (%) |

|---|---|---|---|---|

| Industrial Automation | High-speed operation | ±0.01 mm | 5 | 90 |

| Robotics | Enhanced control and maneuverability | ±0.005 mm | 3 | 85 |

| Aerospace | High reliability and precision | ±0.001 mm | 4 | 95 |

| Medical Equipment | Superior performance in diagnostics | ±0.002 mm | 2 | 92 |

| 3D Printing | Increased printing speed and quality | ±0.01 mm | 6 | 88 |

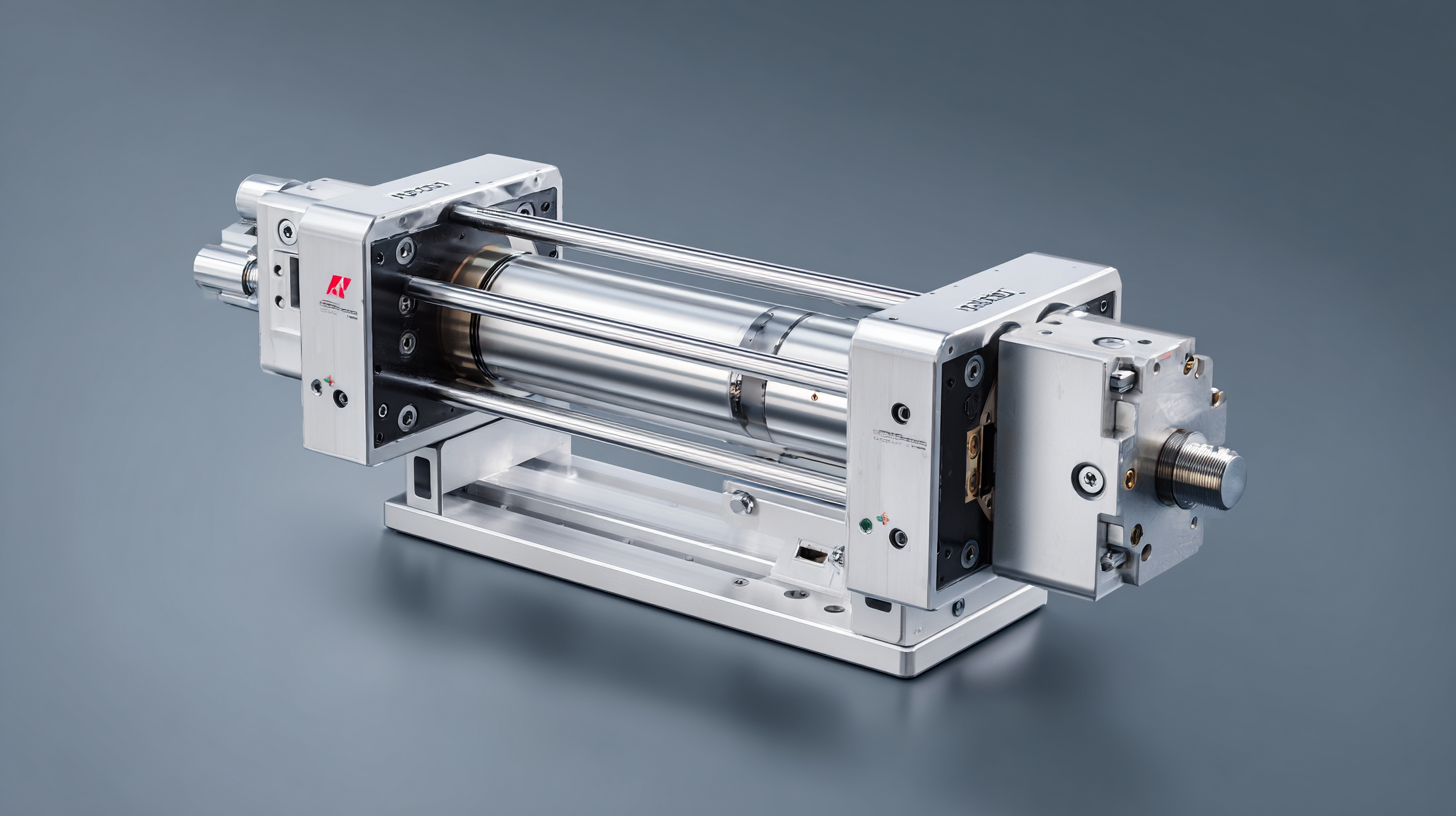

Linear direct drive motors (LDDMs) are transforming industries by providing significant efficiency gains compared to traditional rotary motors. According to a report by the International Electrotechnical Commission (IEC), LDDMs can achieve up to 90% efficiency in specific applications, reducing energy consumption and operational costs. This technology eliminates the need for mechanical components such as gears and belts, which often introduce friction and maintenance requirements, leading to longer system lifespans and reduced downtime.

Linear direct drive motors (LDDMs) are transforming industries by providing significant efficiency gains compared to traditional rotary motors. According to a report by the International Electrotechnical Commission (IEC), LDDMs can achieve up to 90% efficiency in specific applications, reducing energy consumption and operational costs. This technology eliminates the need for mechanical components such as gears and belts, which often introduce friction and maintenance requirements, leading to longer system lifespans and reduced downtime.

Moreover, the precision and responsiveness of linear direct drive motors enhance productivity in various sectors. A study by the Motion Control Association highlights that LDDMs can achieve positioning accuracy within ±5 microns, which is critical in applications such as semiconductor manufacturing and high-speed packaging. As industries increasingly adopt automation and require improved performance, the adoption of LDDMs is projected to grow by 15% annually, reflecting a shift towards energy-efficient and cost-effective solutions that meet modern technological demands.

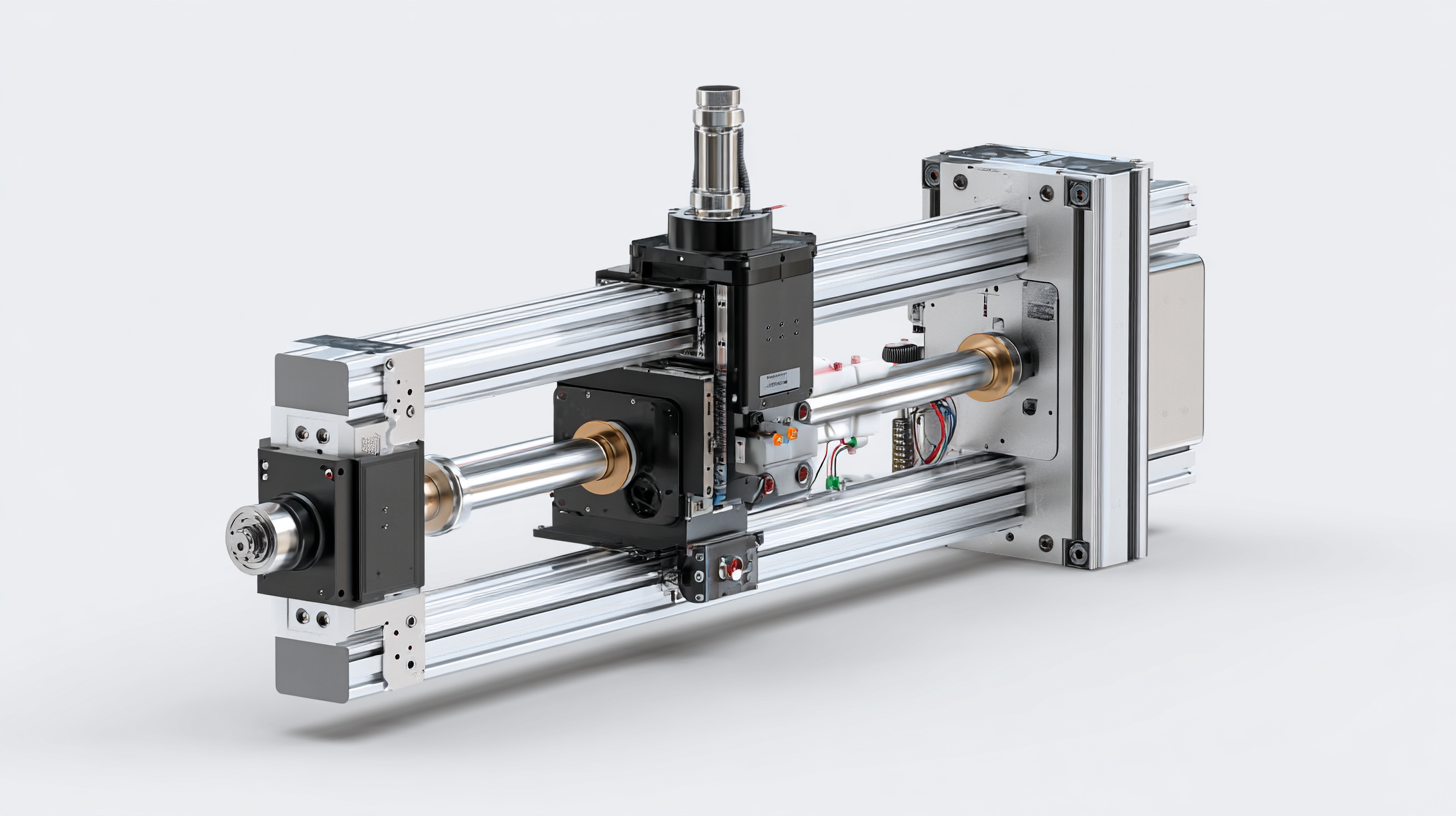

Linear direct drive motors (LDDMs) have become increasingly prominent in the fields of robotics and automation, offering several advantages that enhance performance and efficiency. According to a report by Research and Markets, the global linear motors market is projected to grow from $1.5 billion in 2021 to over $2.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 10%. This growth is primarily driven by the rising demand for high-precision and high-speed automation solutions across various industries.

In robotics, LDDMs provide exceptional positioning accuracy, facilitating complex movements and tasks. For instance, in pick-and-place applications, LDDMs enable robots to operate with a repeatability of ±0.01 mm, which is critical for assembly processes where precision is paramount. Additionally, LDDMs reduce mechanical complexity by eliminating the need for conventional actuators and associated transmission systems, leading to lower maintenance costs and improved reliability. A study by the International Federation of Robotics indicates that the installation of LDDMs in robotic applications can result in energy savings of around 30%, further reinforcing their value in modern automation systems.

Linear direct drive motors are revolutionizing various industries by offering maintenance-free operation, which holds significant benefits for manufacturers and users alike. According to a report by the International Federation of Robotics (IFR), the adoption of linear motors in production systems has surged by 30% in recent years, primarily due to their reliability and reduced operational costs associated with maintenance. By eliminating the need for mechanical transmissions and gearboxes, these motors minimize wear and tear, leading to a markedly lower frequency of service interventions.

The operational efficiency gained through maintenance-free systems can lead to substantial cost savings. As per recent research published by the Institute of Electrical and Electronics Engineers (IEEE), factories equipped with linear direct drive motors have reported up to 25% reduction in maintenance costs and downtime. This reliability allows businesses to allocate resources more effectively, focusing on productivity and innovation rather than routine upkeep. In an era where optimizing operational expenses is paramount for competitiveness, the significance of maintenance-free operation in linear drives cannot be overstated.

Linear direct drive motors (LDDMs) are increasingly favored in modern applications due to their superior performance compared to traditional drive systems. Unlike conventional motors that rely on gears and belts to transfer motion, LDDMs provide a direct connection between the motor and the load, resulting in higher efficiency, reduced maintenance, and enhanced precision. According to a report indicating a steady growth in the linear motor market, industries are gravitating towards these technologies for their capability to support demanding precision motion control requirements. This trend is driven by sectors such as robotics, where compact gearboxes are essential for optimizing space and performance, especially as human-robot interaction (HRI) becomes commonplace.

In terms of comparative analysis, LDDMs offer several advantages over traditional drive systems. Traditional systems often suffer from lag and backlash due to mechanical components, while LDDMs eliminate these issues, allowing for instantaneous response and high-speed operation. Recent advancements in control strategies, such as the improved terminal sliding mode control for linear induction machines, showcase the enhanced dynamic response provided by LDDMs across full speed ranges. As industries seek innovative solutions to enhance operational efficiency and performance, the advantages of linear direct drive motors become increasingly pronounced, positioning them as a vital component in the evolution of modern technology.

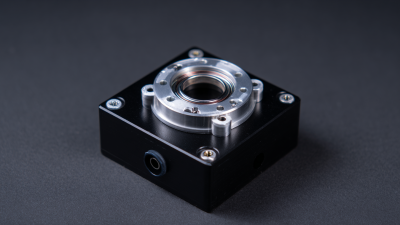

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.