Call Today: 916-259-1868

The future of energy could hinge on innovations in linear magnet motors. As the world seeks cleaner alternatives, this technology stands out. Dr. Emily Carter, a leading expert in electromagnetic systems, notes, “Linear magnet motors could redefine efficiency.” Their potential is vast, but challenges remain.

Linear magnet motors offer precise control and reduced wear over traditional motors. They operate smoothly, providing impressive acceleration in various applications. Despite these benefits, adoption faces hurdles. Costs and manufacturing complexities are significant concerns. The current infrastructure may struggle to integrate this advanced technology.

Exploring the potential of linear magnet motors could lead to breakthroughs. However, the path to widespread use is fraught with uncertainty. The industry must address scalability and economic viability. Balancing innovation with practicality is essential for the future. The question remains: will linear magnet motors truly transform our energy landscape?

Linear magnet motors (LMMs) have evolved significantly in recent years, marking their growing presence in the energy sector. These motors utilize magnetic fields to create linear motion, which can enhance efficiency in various applications. According to recent data from industry reports, the market for linear magnet motors is expected to grow by 20% annually through 2026. This increase reflects a broader trend toward more sustainable energy solutions.

Tips: Explore the differences between various types of linear motors. Knowledge is key.

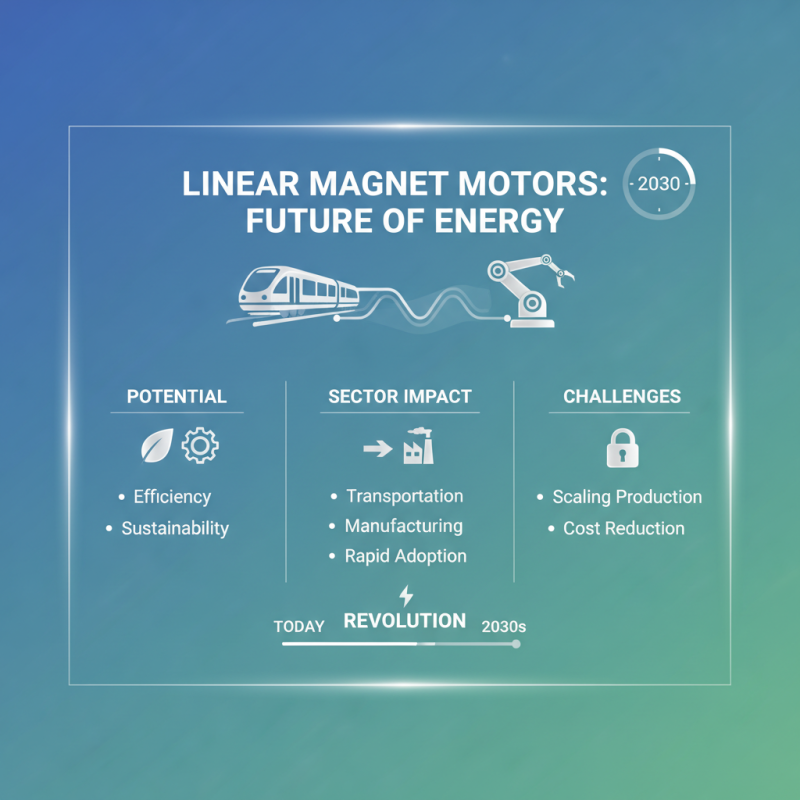

Innovations in LMM technology include their integration into transportation systems. For instance, some urban transit systems are adopting magnetic levitation trains powered by linear motors. These trains can travel at remarkable speeds with low energy consumption. However, there are still challenges to overcome. Costs for implementation and maintenance can be high.

Tips: Consider the lifecycle costs of technology before investing.

The use of LMMs in renewable energy cycles, such as wind turbines, shows promise. They can enhance the adaptability of turbines, allowing them to adjust to changing wind conditions efficiently. Yet, the technology is not yet perfect. Technical issues and reliability concerns could hinder widespread adoption. Research and development are crucial to address these gaps and push LMM advancements further.

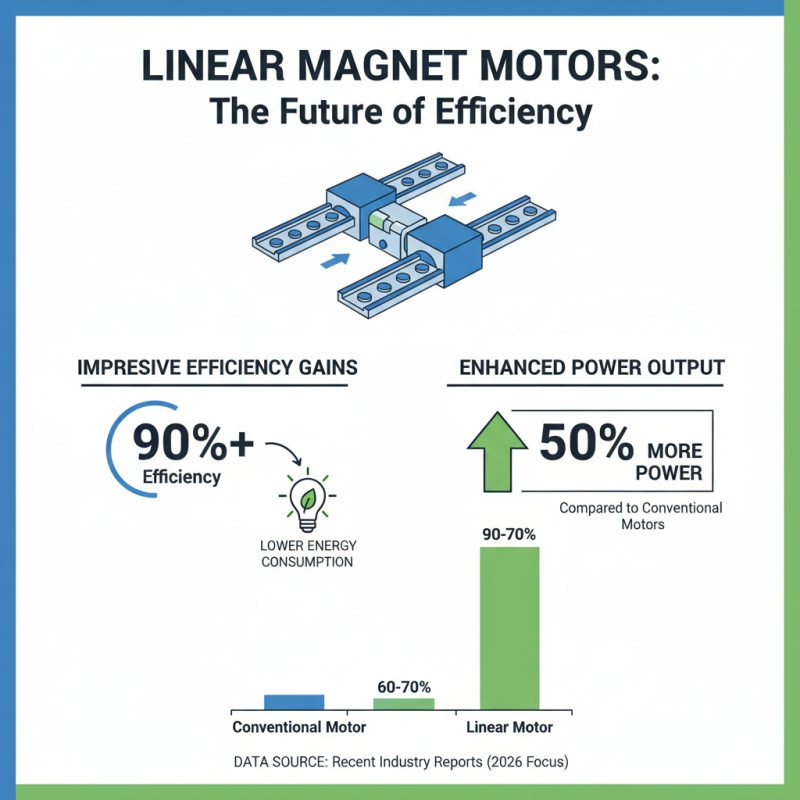

This chart illustrates the estimated efficiency improvements in linear magnet motors over recent years, showcasing their potential impact on the energy sector by 2026.

The advancements in linear magnet motor technology in 2026 are remarkable. These motors offer higher efficiency and lower maintenance compared to traditional systems. The efficiency rate can reach up to 95%, a significant improvement over older technologies. This increase in performance can lead to substantial energy savings in various applications.

Industry analysts predict the linear magnet motor market will grow by over 12% annually. This growth reflects the rising demand for innovative, sustainable energy solutions. The motors' ability to provide direct linear motion with minimal friction is game-changing. They can be used in transportation, industrial automation, and renewable energy sectors. This versatility makes them appealing to a wide range of industries.

However, challenges remain. Manufacturing costs are still high, making widespread adoption difficult. Reliability in different operational environments is another concern. While the promise of lower operational costs exists, the initial investment can deter potential users. These are areas requiring further innovation and reflection. Addressing these issues will be crucial for the sector's long-term sustainability and growth.

As we approach 2026, the potential of linear magnet motors is worth examining. These motors promise impressive efficiency gains. According to recent industry reports, linear motors can reach efficiencies above 90%, a significant leap compared to conventional motors. This translates to lower energy consumption and better power output. For example, a linear motor can produce up to 50% more power in the same operational settings.

Tips: Consider how the design of these motors influences performance. Factors like coil arrangement and magnetic configuration play crucial roles. They can significantly affect both the torque and speed achieved. Testing different formats could lead to breakthrough applications.

Even with these benefits, challenges remain. The cost of materials could hinder widespread adoption. Manufacturers need to balance performance enhancements with affordability. As technology evolves, reflections on these trade-offs will be essential to ensure sustainable growth in the industry.

Linear magnet motors (LMMs) are garnering attention as viable alternatives to traditional energy solutions. Unlike conventional motors, LMMs employ magnetic levitation. This innovative approach reduces friction and increases efficiency. According to recent data from energy sector reports, LMMs can achieve efficiency levels above 90%. Traditional solutions, in contrast, often operate below 80% efficiency.

Moreover, LMMs offer scalability that traditional motors struggle to match. They can be customized for various applications, from transportation to industrial machinery. However, the initial development costs are a barrier. Many companies are still exploring funding options to conduct further research. Reports indicate that LMM technology may require substantial investment to reach maturity.

Yet, concerns linger. Reliability over time is still being evaluated. With traditional motors, longevity is well understood. In contrast, LMM technology is relatively new. Data shows that real-world applications are limited. This raises questions about long-term performance. As the industry evolves, careful analysis is crucial. The potential impact on energy efficiency and sustainability remains promising but is far from guaranteed.

| Feature | Linear Magnet Motors | Traditional Energy Solutions |

|---|---|---|

| Efficiency | 85-90% | 40-60% |

| Maintenance | Low | High |

| Cost of Production | Medium | Low |

| Environmental Impact | Minimal | Substantial |

| Scalability | High | Limited |

| Application Versatility | Wide | Narrow |

The future landscape of energy may be revolutionized by innovations in linear magnet motors. Forecasts suggest that by 2030, these motors could transform multiple sectors. Their potential lies in efficiency and sustainability. Many experts predict rapid adoption rates, particularly in transportation and manufacturing. However, challenges remain in scaling production and reducing costs.

Tips: Consider exploring niche applications for linear magnet motors. They can be ideal for small-scale projects. Start small to understand their unique benefits.

Despite their promise, skepticism exists. Technical hurdles and market readiness need addressing. Not every application will benefit equally. Companies must evaluate whether the benefits outweigh the challenges before fully committing to these technologies.

Tips: Investors should remain cautious. Engage with industry experts to assess feasibility. Flexibility in approach can lead to innovative solutions. Take the time to experiment and refine processes as you explore this evolving field.

Sierramotion engineers help customers design solutions to complex motion problems. Whether a simple coil, or a precision motion assembly working in vacuum, Sierramotion has the experience to create a solution that works the first time.